Composite measurement system and measurement method of laser line scanning and shadow Moire measurement

Technology of a measurement system, laser line, used in the field of optical inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is described in further detail below in conjunction with accompanying drawing:

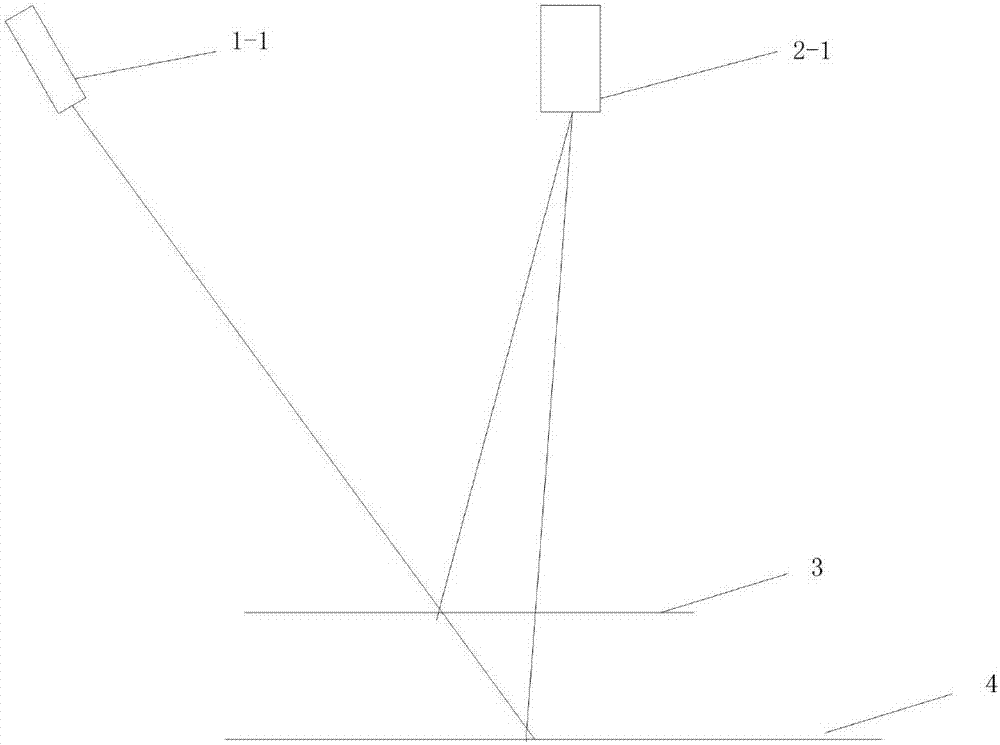

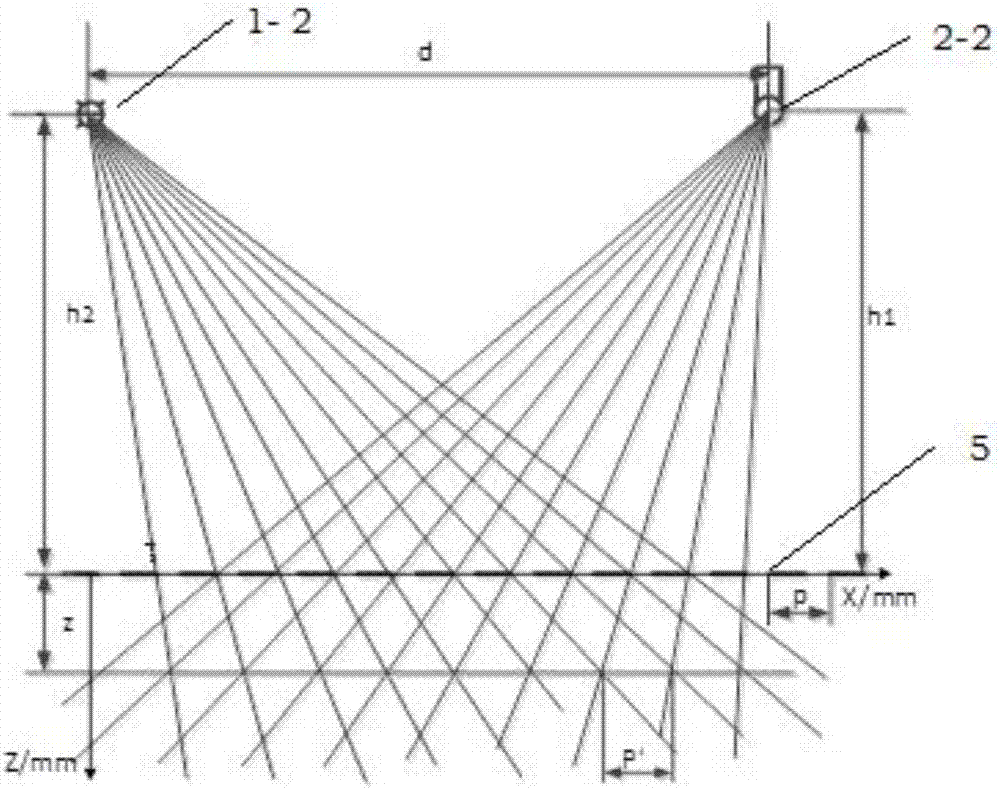

[0065] see figure 1 , 2 And 3, a laser light knife and shadow moiré fusion measurement method, specifically comprising the following steps:

[0066] The first step is to calibrate the system parameters.

[0067] Both the shadow moiré measurement system and the laser line scan measurement system require accurate calibration of system parameters. The parameters that need to be calibrated are: camera internal reference, projector internal reference, positional relationship among grating, projector, and camera. When the aperture and focal length of the camera are adjusted and the calibration plate is prepared, the calibration can be carried out. The calibration steps are as follows:

[0068] 1. Camera calibration and camera grating relative position calibration. Place the calibration board in the field of view of camera 2-3, change the pose of the calibration board, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com