Automatic production device for bed cloth

A technology of production equipment and bedcloth, which is applied in the field of automatic production equipment for bedcloth, can solve problems such as different thickness and density, unguaranteed precision, and impact on production efficiency, so as to reduce production costs, avoid needle movement errors, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

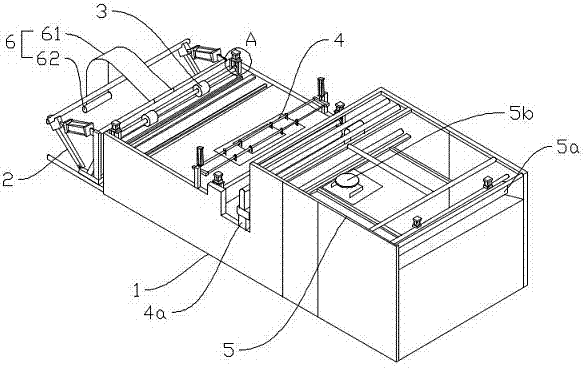

[0021] The technical scheme in the embodiment of the present invention is described below in conjunction with accompanying drawing:

[0022] like Figure 1-4 As shown, a kind of automatic bedcloth production equipment provided by the present invention includes and sequentially connected cloth loading device, cloth hemming device 4, cloth edge sewing device 4a, and cloth cutting mechanism 5b, wherein the cloth loading device It includes an upper cloth frame 2 and a cloth pressing device 3. The upper cloth frame 2 includes a frame body arranged on one side and a cloth holding frame arranged on the left side of the frame body. The cloth holding frame and the bottom of the frame body are hinged , the cloth holding frame is connected with the top of the frame body through a cylinder, the cloth holding frame can rotate, and a cloth pressing mechanism 6 is also arranged between the cloth holding frame and the frame body, and the cloth pressing mechanism 6 includes Cloth pressing bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com