Efficient sole pressing machine for shoemaking

A sole pressing machine and high-efficiency technology, applied in the direction of shoe-making machinery, soles, footwear, etc., can solve the problems of inconvenient time grasping, reducing the working efficiency of the sole pressing machine, and inconvenient for the stable transportation of shoes, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

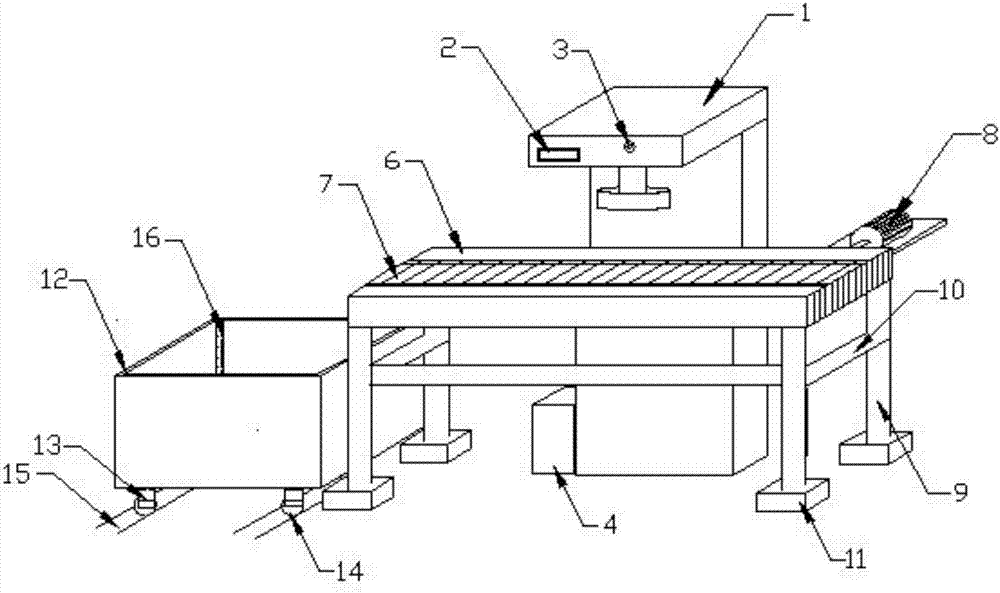

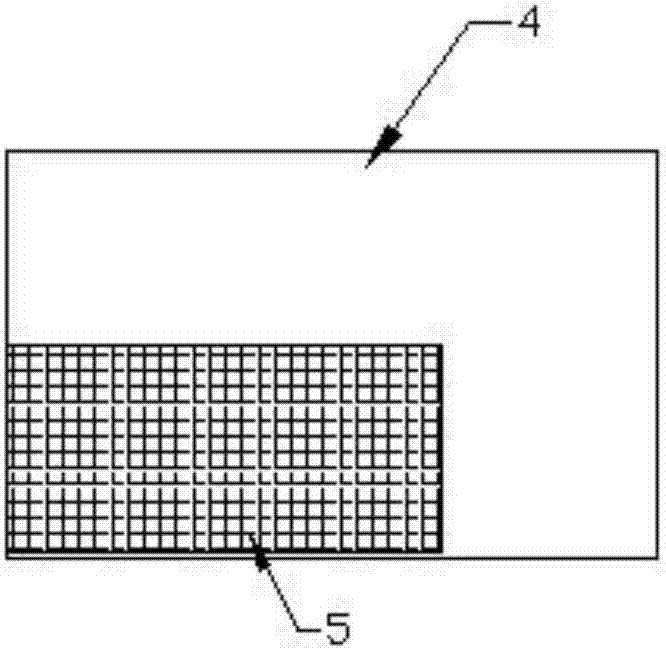

[0018] Example: such as Figure 1-2 As shown, the present invention provides a high-efficiency sole pressing machine for shoemaking, comprising a sole press body 1, an electronic watch 2 is provided on one side of the upper part of the sole press body 1, and an indicator light 3 is provided on one side of the electronic watch 2 , one side of the bottom of the indicator light 3 is provided with a control box 4, the interior of the control box 4 is provided with a controller 5, the bottom of the bottom pressing machine body 1 is provided with a conveying platform 6, and the top of the conveying platform 6 is provided with a conveyor belt 7. One side of the platform 6 is provided with a motor 8, the bottom end of the transmission platform 6 is provided with a support rod 9, one side of the support rod 9 is provided with a stabilizing bar 10, and the bottom end of the support rod 9 is provided with a stable base 11, and the transmission platform 6 The bottom of one end is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com