Acoustic sensor for monitoring rock burst

An acoustic sensor and rockburst technology, applied in scientific instruments, instruments, seismology, etc., can solve problems such as undeliverable, easy to wear out cables or acoustic emission probes, time-consuming and labor-intensive problems, to ensure coupling effect and enhance monitoring The effect on forecast reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

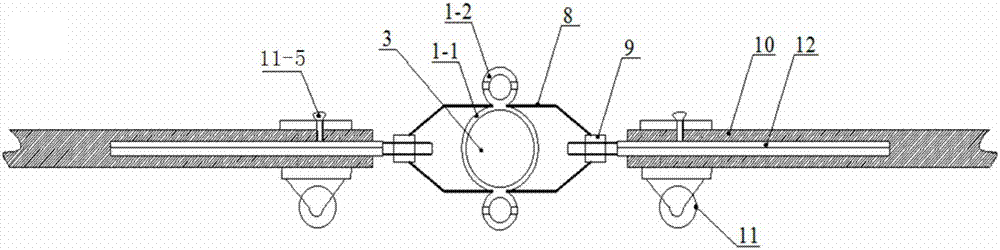

[0050] The rockburst monitoring acoustic sensor that present embodiment provides, as figure 1 As shown, the acoustic emission probe 3, the probe installation mechanism and the combination of the acoustic emission probe and the probe installation mechanism are transmitted to the transmission mechanism set in the borehole of the monitored rock mass; the probe installation mechanism and the acoustic emission probe 3 The quantity is one.

[0051] like Figure 4 , Figure 5 As shown, the above-mentioned acoustic emission probe 3 is a cylindrical structure with a cable connector 3-1 extending from the side, and one end of the acoustic emission probe is coated with butter.

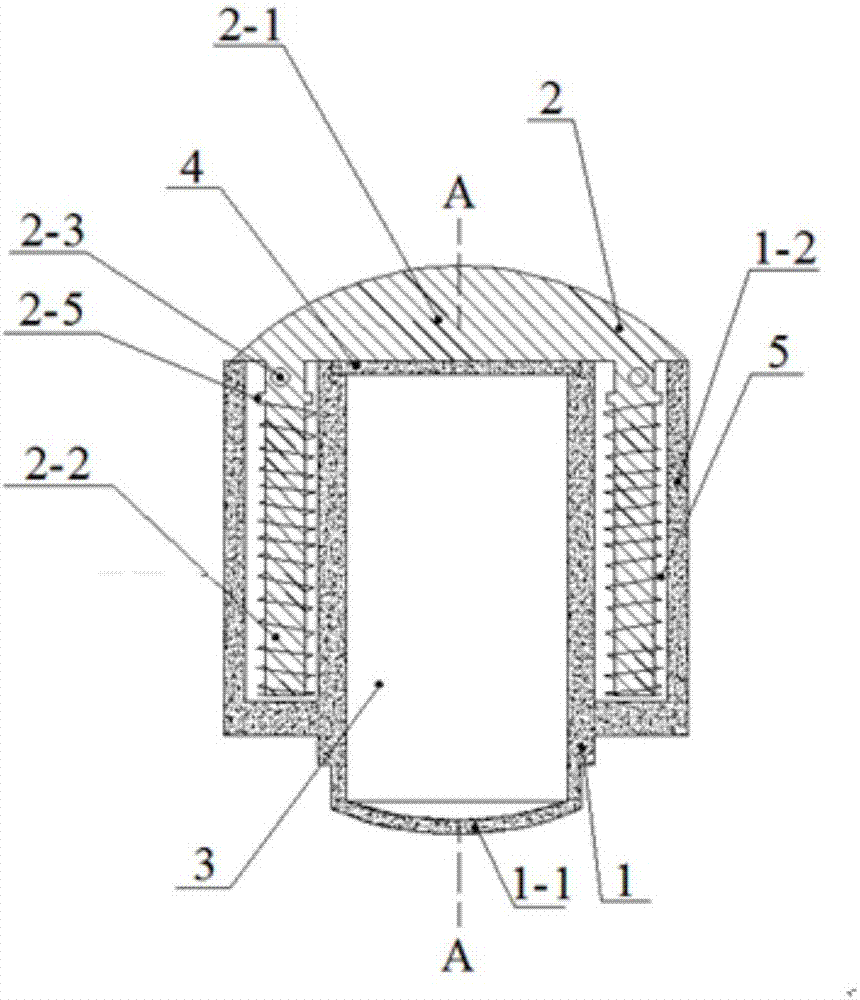

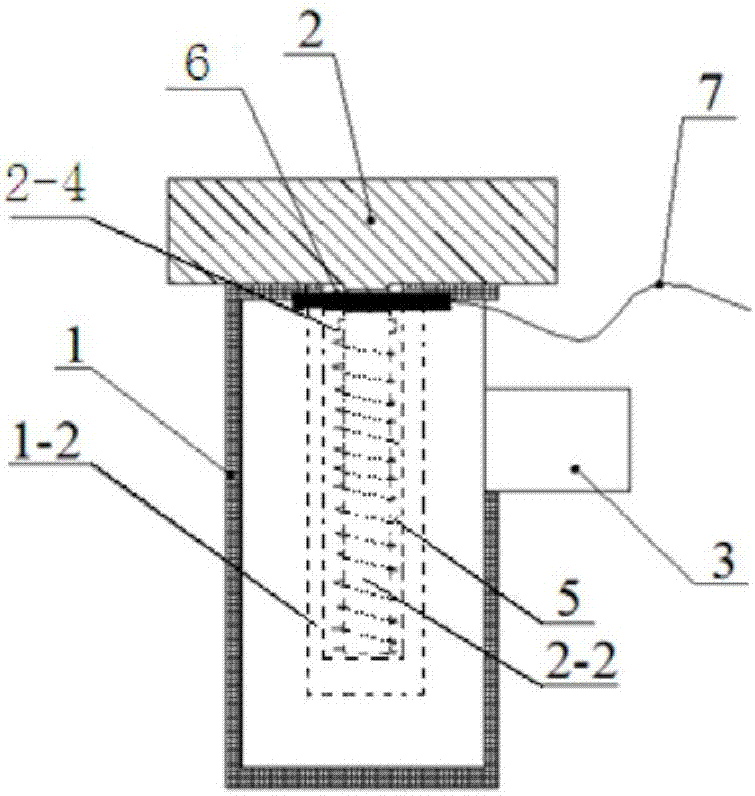

[0052] like Figure 1 to Figure 3 As shown, the above-mentioned probe installation mechanism is mainly composed of a sleeve assembly 1, a guide assembly 2, an end cover 4, a spring 5, a limit pin 6 and a connecting assembly.

[0053] like figure 2 , image 3 and Figure 6 As shown, the above-mentioned sle...

Embodiment 2

[0064] The acoustic sensor for rockburst monitoring provided in this embodiment is composed of an acoustic emission probe, a probe installation mechanism, and a transmission mechanism that transmits the combination of the acoustic emission probe and the probe installation mechanism to the set position in the borehole of the monitored rock mass; The number of the mechanism and the acoustic emission probe are both one.

[0065] The transmission mechanism provided in this embodiment is the same as the transmission mechanism provided in Embodiment 1.

[0066] The probe installation mechanism provided in this embodiment is basically the same as the probe installation mechanism given in Embodiment 1. In view of this embodiment, the guide assembly 2 and the sleeve are realized through the pluggable connection between the guide assembly 2 and the end cover 4. The moving direction of the barrel assembly 1 is controlled. In this embodiment, certain improvements are made to the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com