Automatic barreled garbage collecting device

A technology for automatic collection and garbage collection vehicles, applied in the field of garbage collection vehicles, can solve problems such as adverse effects on human health and safety of use, large physical energy consumption of the human body, etc., and achieve the effects of low cost, reduced labor intensity, and simple design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

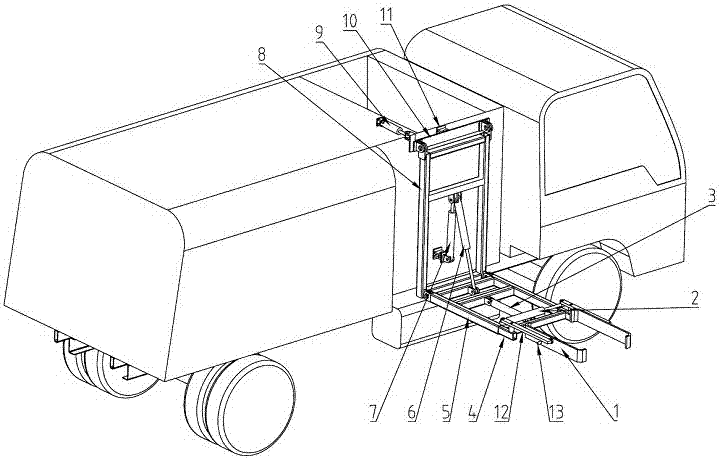

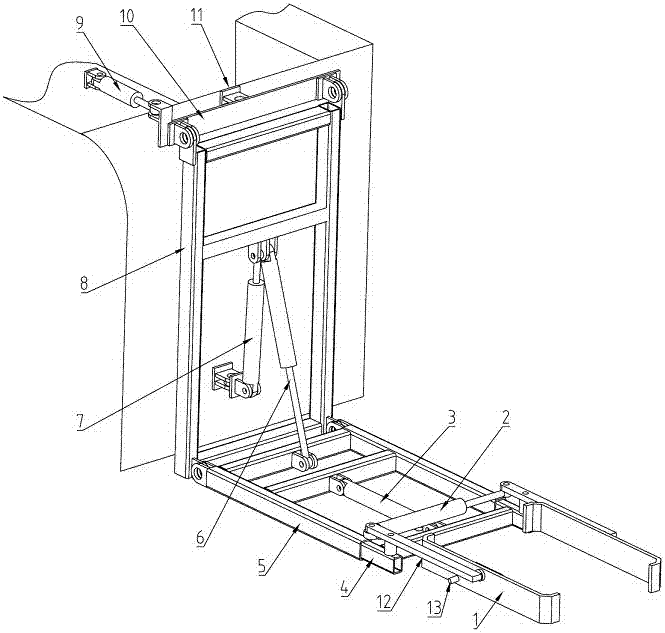

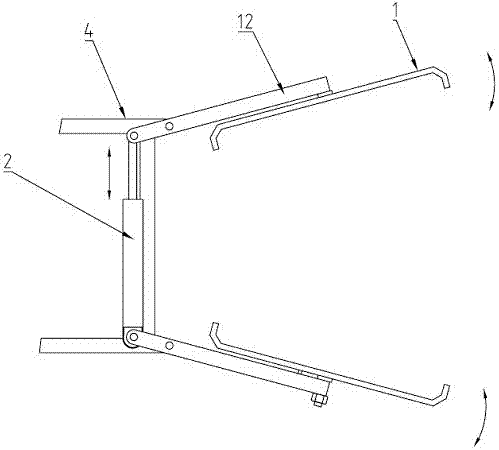

[0019] The device includes a clamping mechanism, a translation lifting and turning mechanism. like figure 1 , figure 2 , image 3 As shown, the clamping mechanism includes a splint 1, a clamping oil cylinder 2, and a clamping arm 12. Two splints 1 and a clamping arm 12 are arranged opposite to each other, and the two ends of the clamping oil cylinder 2 (a section of the bottom surface of the oil cylinder chamber and the connecting rod of the oil cylinder The top) is hingedly connected to one end of each clamping arm 12, and the other two ends of the two clamping arms 12 are connected to the middle outer walls of the two splints 1 in a rotatable and movable connection, and each splint 1 Fixed limit shaft 13 on the outer wall, the effect of limit shaft 13 is after splint 1 clamps garbage can, limit shaft 13 limits the rotation angle of splint 1 and clamping arm 12. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com