Sandwich treatment method of antibacterial non-natural leather

A treatment method, non-natural technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problem of non-natural leather antibacterial treatment that cannot be finished

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

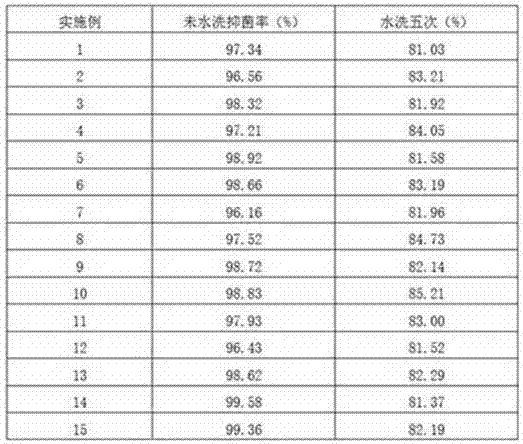

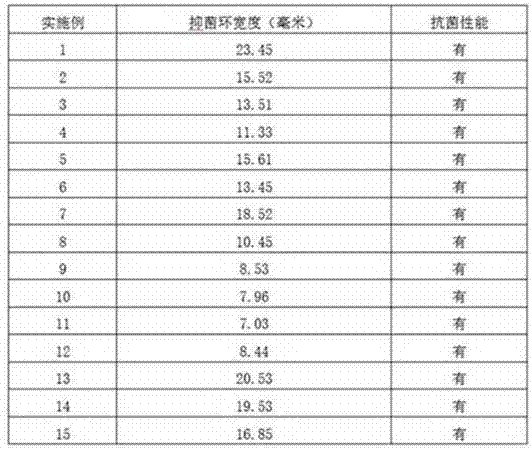

Examples

Embodiment 1

[0019] Use nano-silver antibacterial agent as the first layer, press 100g / m 2 Spray evenly on the base surface of the synthetic leather, and dry it at 50°C; then mix the nano-silver antibacterial agent and polyurethane in a mass ratio of 1:1 as the second layer, and press 80g / m 2 Spray evenly on the base surface of the synthetic leather, and dry it at 50°C; use pure polyurethane resin as the third layer at 50g / m 2 The amount is uniformly sprayed onto the base surface of the synthetic leather, then placed on the condition of 50°C for drying, and finally ironed once at 100°C under a pressure of 70Kg to obtain antibacterial non-natural leather.

Embodiment 2

[0021] Use nano silver as the first layer, according to 110g / m 2 The amount is evenly sprayed onto the base surface of the artificial leather, and placed at 55°C for drying; then the nano-silver antibacterial agent and polyacrylic resin are mixed in a mass ratio of 1:10 as the second layer, and the weight is 90g / m 2 Spray evenly on the base surface of the artificial leather, and dry it at 55°C; use pure polyacrylic resin as the third layer at 60g / m 2 The amount is evenly sprayed onto the base surface of the artificial leather, then placed on the condition of 50°C for drying, and finally ironed once at 100°C under a pressure of 70Kg to obtain antibacterial non-natural leather.

Embodiment 3

[0023] Use nano-zinc oxide as the first layer, according to 120g / m 2 Spray evenly on the base surface of the microfiber leather, and dry it at 55°C; then mix nano-zinc oxide and butadiene resin in a mass ratio of 1:20 as the second layer, and weigh 100g / m 2 Spray evenly on the base surface of the microfiber leather, and place it at 60°C for drying; use pure butadiene resin as the third layer at 70g / m 2 Spray evenly on the base surface of the microfiber leather, then dry it at 55°C, and finally iron it once at 100°C under a pressure of 70Kg to obtain an antibacterial non-natural leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com