Novel intermediate beam structure for hydraulic press

A technology of hydraulic press and intermediate beam, which is applied in the manufacture of intermediate beam of hydraulic press and the manufacture of intermediate beam of four-column hydraulic press, can solve the problem of excessive material consumption, and achieve the effects of reducing energy consumption, reducing and absorbing vibration of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention. It designs a rib plate structure, which is suitable for the middle beam of the existing four-column hydraulic press. It not only increases the equivalent stiffness of the middle beam, but also improves the vibration absorption capacity, realizes the light weight of the middle beam body, thereby improving the reliability and service life of the hydraulic press, and should be vigorously promoted.

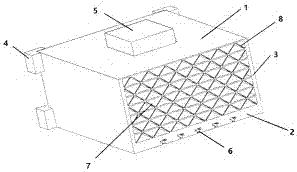

[0012] Such as figure 1 with figure 2 As shown, a novel middle beam structure of a hydraulic machine in the present invention is characterized in that it includes a lower panel 2 and an upper panel 1 arranged on the lower panel 2, and the lower panel 2 and the lower panel 1 are connected by a beam wall 3, A plurality of ribs 8 are arranged between the upper panel 1 and the lower panel 2, and the angle between two adjacent sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com