Cleaning liquid spraying device and cleaning liquid spraying method

A technology of spraying device and spraying method, which is applied in the direction of spraying device, spraying device, cleaning method and utensils, etc., can solve the problems such as the deterioration of the appearance of the steel plate surface, and achieve the effect of preventing nozzle clogging and suppressing spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

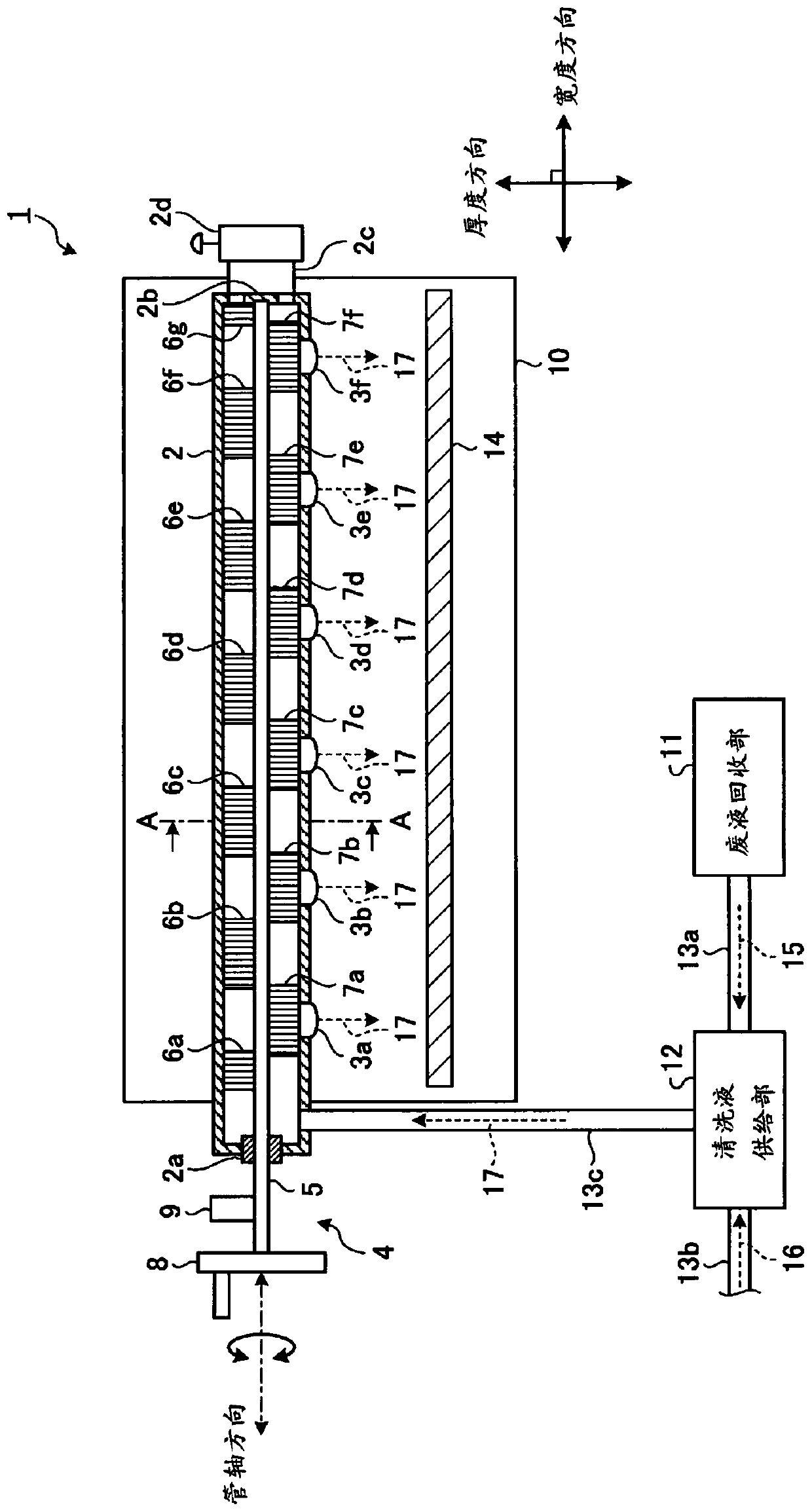

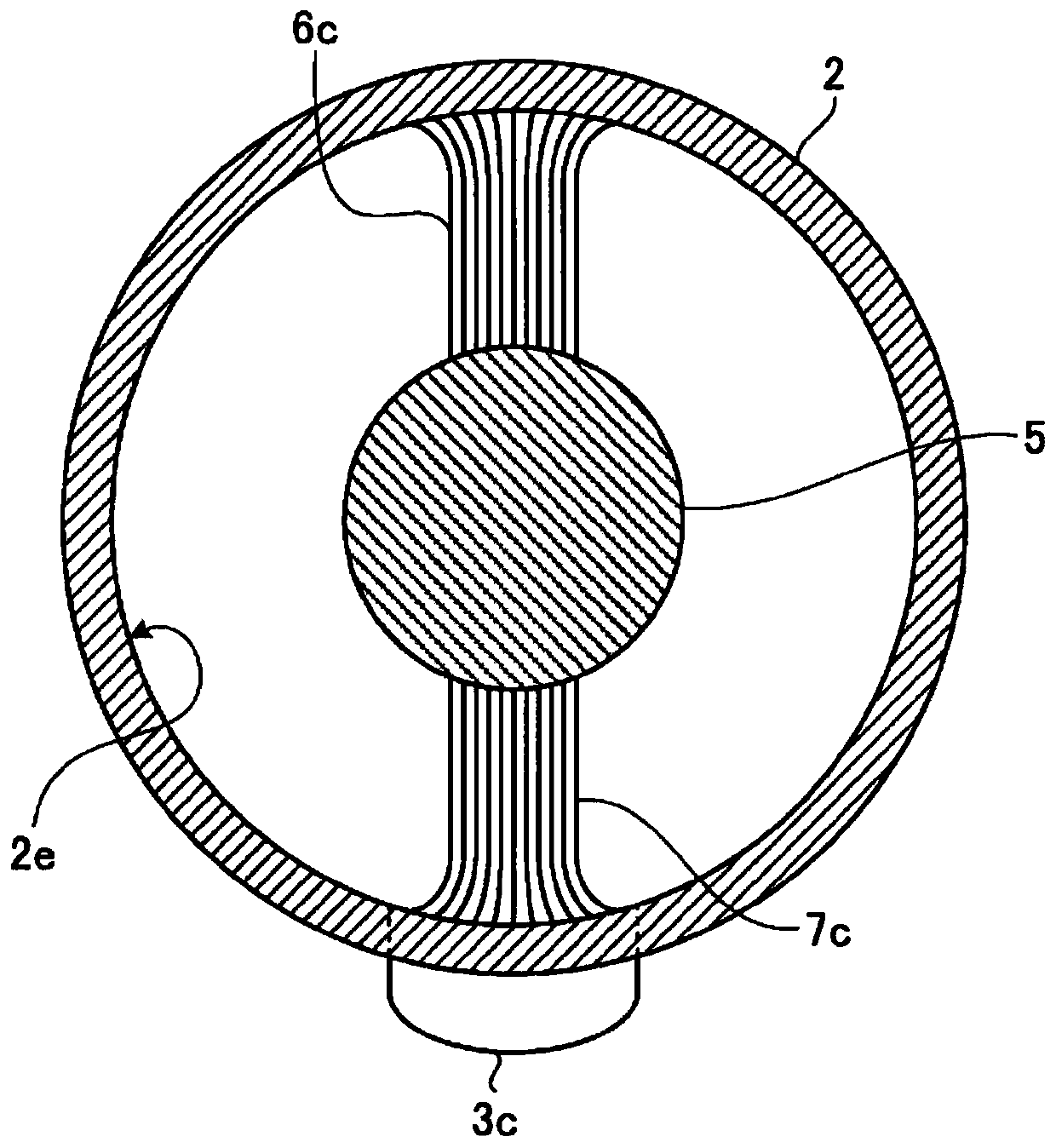

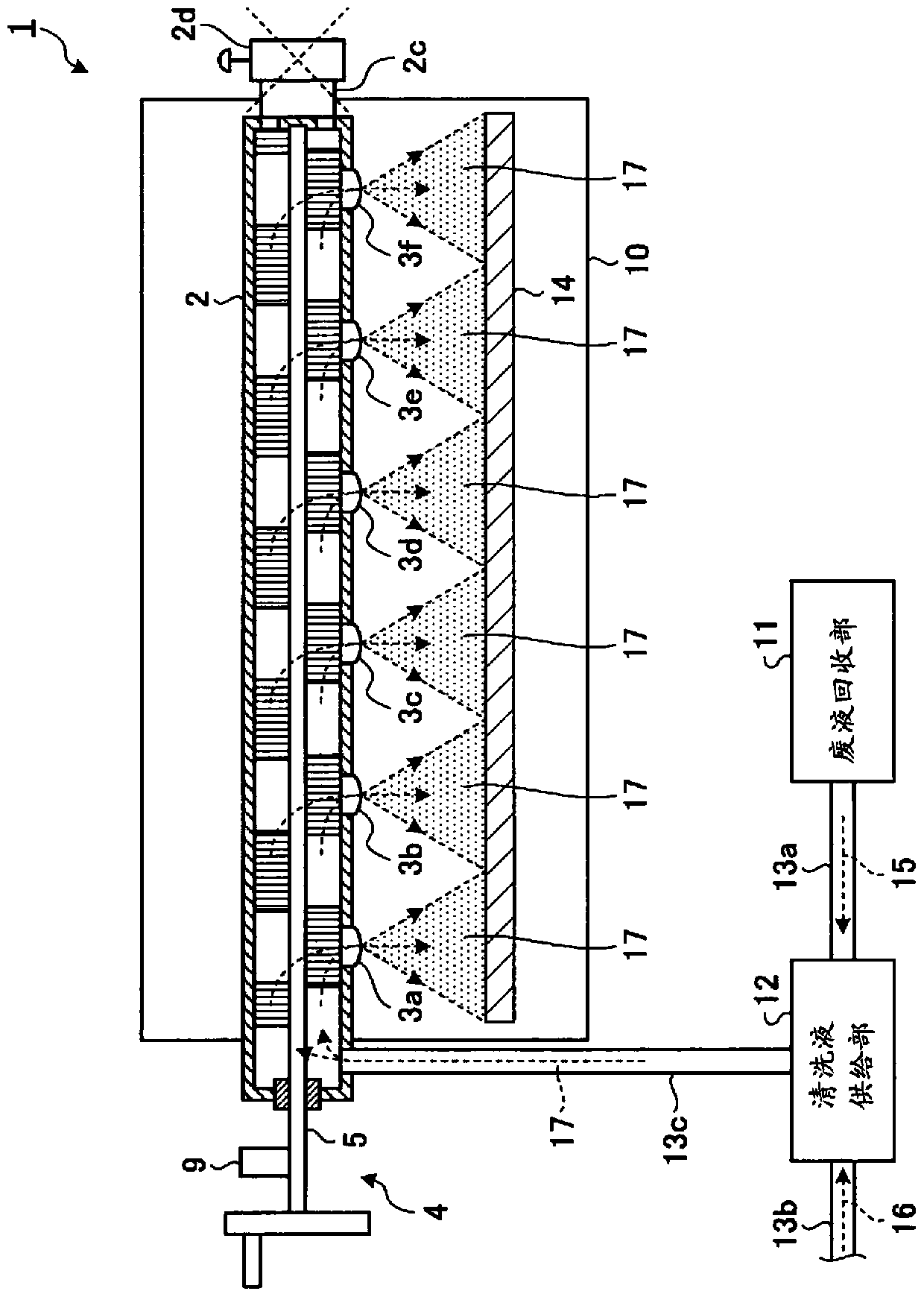

[0029] First, the configuration of the cleaning liquid spraying device according to Embodiment 1 of the present invention will be described. figure 1 It is a diagram showing a configuration example of the cleaning liquid spraying device according to the embodiment of the present invention. figure 2 is showing figure 1 A cross-sectional view along line A-A of the schematic structure inside the spray piping of the cleaning liquid spraying device shown. like figure 1 , 2 As shown, the cleaning liquid injection device 1 according to the embodiment of the present invention includes: a spray pipe 2 provided with spray nozzles 3 a to 3 f for spraying a cleaning liquid 17 ; and a rotary brush 4 for cleaning the inside of the spray pipe 2 and the magnetization portion 9, which magnetizes the rotating shaft 5 of the rotating brush 4 appropriately. In addition, the cleaning liquid injection device 1 includes: a housing 10 forming a cleaning space for performing a cleaning process; a...

Embodiment approach 2

[0073] Next, Embodiment 2 of the present invention will be described. In the first embodiment described above, the hard magnet (permanent magnet, etc.) of the magnetized portion 9 that switches the rotating shaft 5 of the rotating brush 4 between a magnetized state and a non-magnetized state is arranged outside the rotating shaft 5, but in the second embodiment , a hard magnet for switching between a magnetized state and a non-magnetized state is provided inside the rotating shaft of the rotating brush 4 .

[0074] on the one hand, Figure 8 It is a diagram showing a configuration example of a cleaning liquid spraying device according to Embodiment 2 of the present invention. like Figure 8 As shown, the cleaning liquid spraying device 21 according to the second embodiment includes a rotating shaft 25 instead of the rotating shaft 5 of the rotating brush 4 of the cleaning liquid spraying device 1 according to the first embodiment described above, and a magnetized part 29 ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap