A conductive slip ring with two contact functions of rotation and slip ring at the same time

A conductive slip ring, conductive ring technology, applied in the directions of non-rotating current collectors, rotating current collectors, connections, etc., can solve problems such as the inability to meet the transmission of various signals, achieve the transmission of electrical signals, widen application fields, The effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

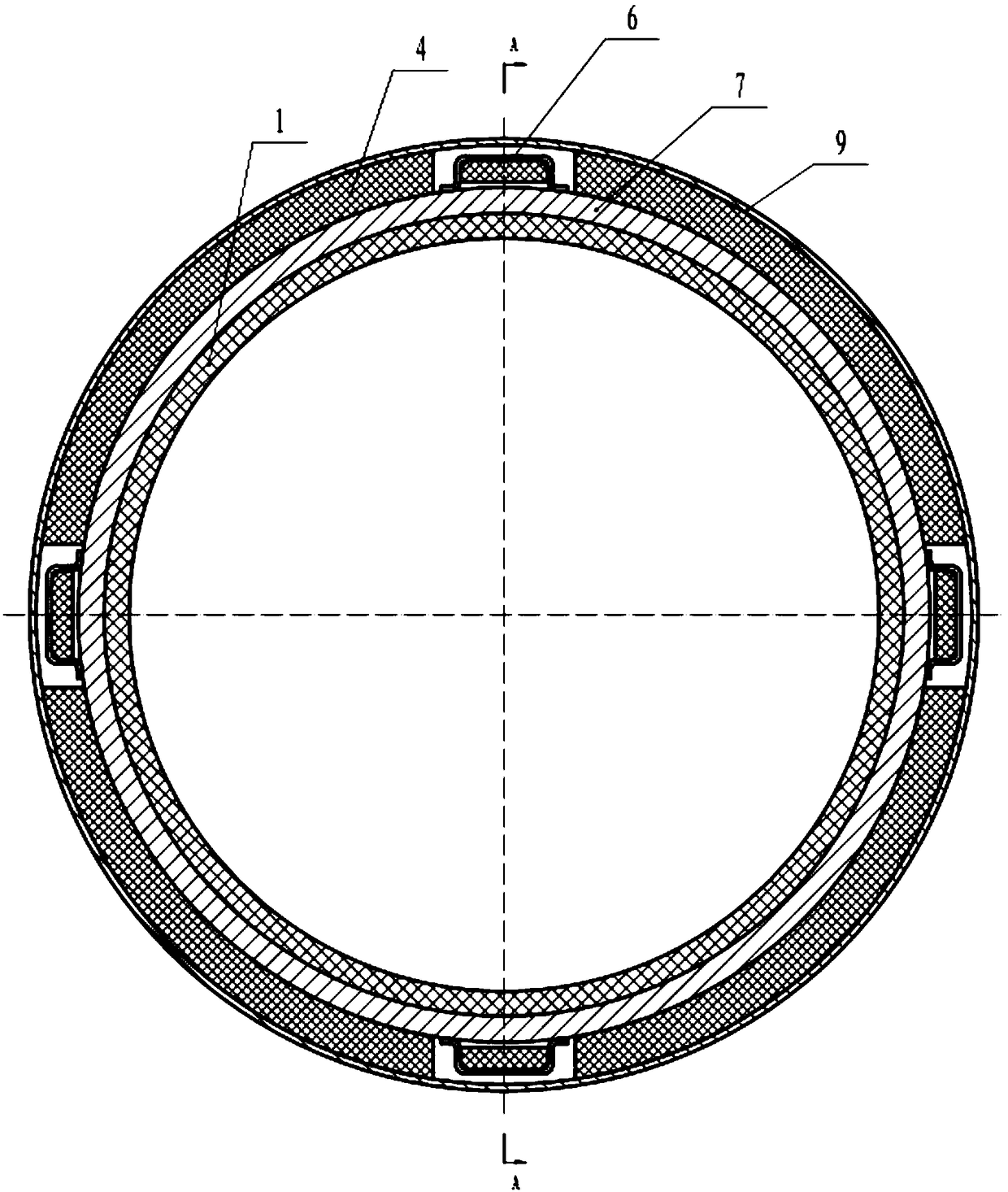

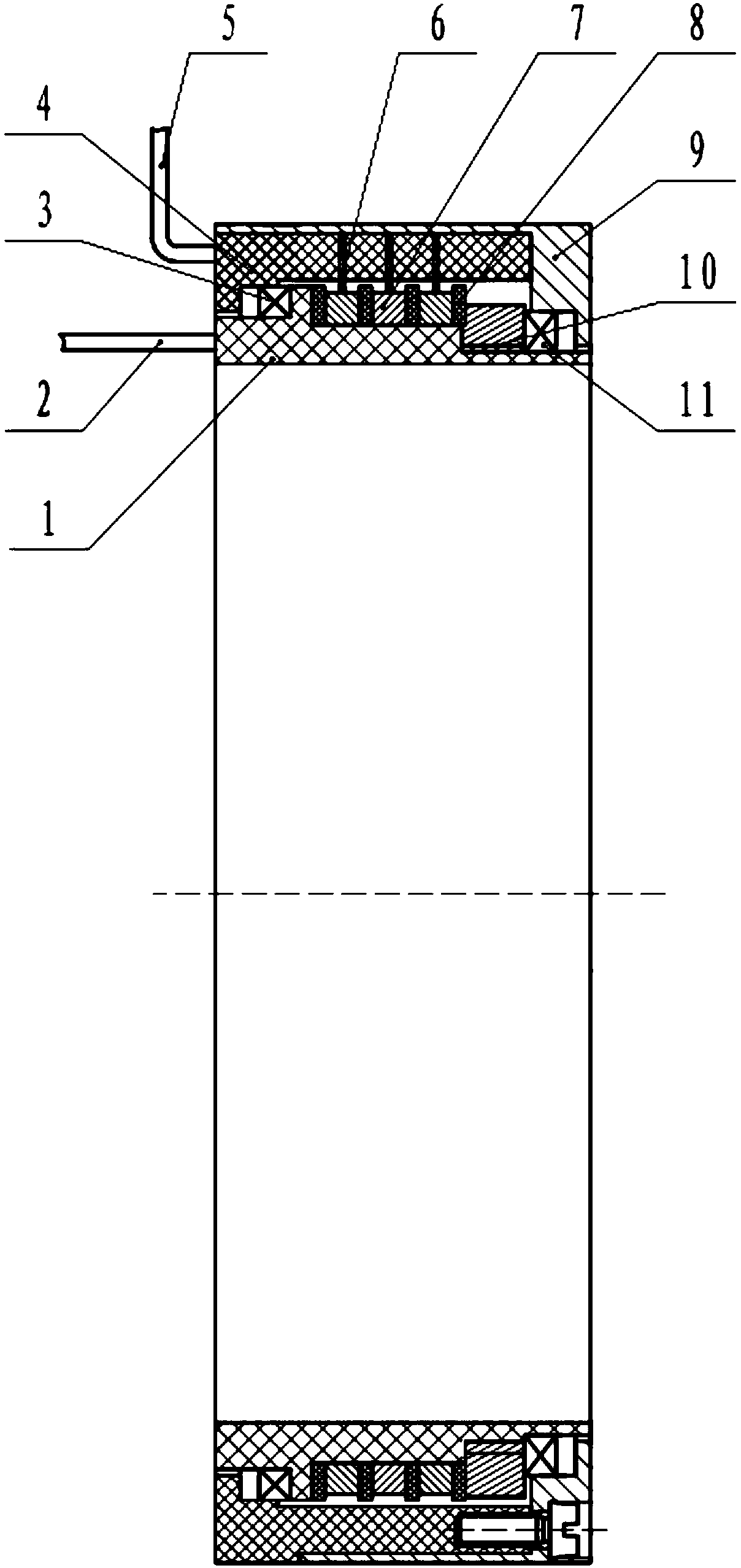

[0021] Such as figure 1 , figure 2 As shown, the conductive ring 7 and the insulating ring 8 welded with the rotor wire 2 are installed on the rotor shaft 1 of the conductive slip ring, and the rotor wire 2 is drawn out from the lead groove on the rotor shaft 1; and the conductive ring 7 and the insulating ring 8 Assembling, one side is fixed with a top nut 10, and the other side is close to the raised structure of the side wall of the rotor shaft 1.

[0022] After installing the sliding bearing I3 on one side of the rotor shaft 1, install the stator frame 4, and ensure that the two-way axial sliding displacement is more than 0.5mm each, and they can rotate freely within 360°.

[0023] The brush 6 welded with the stator wire 5 that is in sliding contact and rotational contact with the conductive ring 4 is installed on the stator frame 4, and fixed with epoxy glue. The stator wire 5 is drawn out from the lead groove on the stator frame 4.

[0024] After installing the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com