Vertical gluing machine

A melter, vertical technology, applied in the direction of surface pretreatment, coating, device for coating liquid on the surface, etc., can solve the problems of slow production speed and high energy consumption, reduce traction tension, improve work efficiency, improve The effect of increased warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

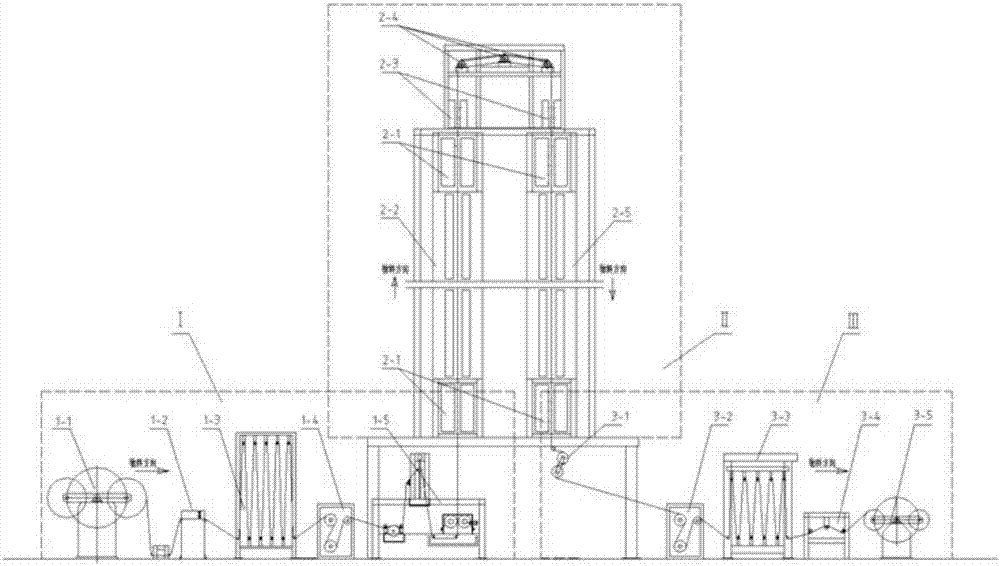

[0022] Vertical gluing machine of the present invention, as figure 2 As shown, it includes front-end equipment 1, drying unit 2 and back-end equipment 3 which are connected in sequence. There are multiple edge guides 4 .

[0023] The drying unit 2 comprises a hot air airtight box 12-1 and a descending oven 2-2 arranged below the hot air airtight box 12-1, the downward oven 2-2 is connected with a steering device 2-3, and the steering device 2-3 is It is also connected with an ascending oven 2-4, and the ascending oven 2-4 is connected with a hot air airtight box II2-5.

[0024] Such as image 3 As shown, the steering device 2-3 is installed between the outlet of the descending oven 2-2 and the outlet of the ascending oven 2-4, and its structure is: comprising fresh air filter boxes 2-3-1, Fresh air preheating box 2-3-2, hot air blower 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com