Air filtering net convenient to assemble and disassemble and used for workshop

An air filter, workshop technology, applied in membrane filters, dispersed particle filtration, applications, etc., can solve the problems affecting the stability of the filter, secondary pollution of the environment, loose installation holes, etc., to enhance the purification and filtration effect, convenient The effect of disassembly for cleaning or repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions and beneficial effects of the present invention will be further described and illustrated below in conjunction with the accompanying drawings.

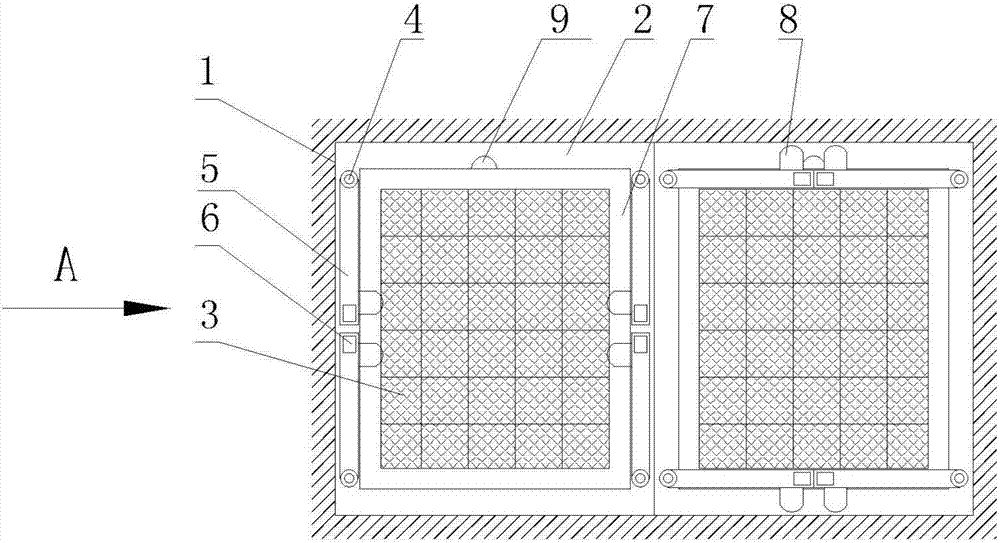

[0039] see figure 1 , with reference to Figure 2-Figure 7 , the figure shows a convenient detachable workshop air filter related to the present invention.

[0040] One of its key technical solutions lies in:

[0041] Such as figure 1 , 2 As shown, the workshop air filter that is easy to disassemble is installed in the groove 1 set on the wall N in the factory workshop, and one or more filter screens are arranged in the groove 1 of the wall from the outside to the inside. Frame mounting seat 2, filter screen frame 7 and inner frame 10 with filter screen 3.

[0042] The filter screen frame mounting seat 2 is embedded on the inner wall of the wall groove 1, the filter screen frame 7 is closely attached to the inner wall of the filter screen frame mounting seat 2, and the inner frame 10 with the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com