Seed sowing machine

A technology of seeding machine and seeding mechanism, applied in the direction of manual seeding tools, etc., can solve the problems of high cost, low efficiency, high labor intensity, etc., and achieve the effect of light weight, small volume, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

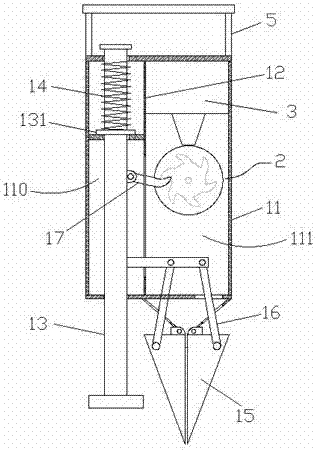

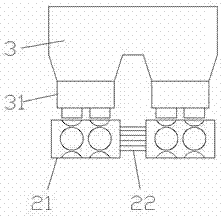

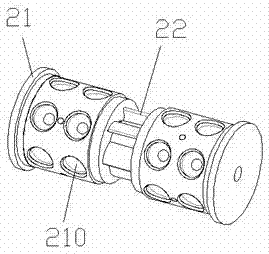

[0023] Such as Figure 1 to Figure 3 As shown, a planter of the present invention includes a housing 11, a first partition 12, a pressing rod 13, a spring 14, a cone mouth 15, a first connecting rod 16, a driving tooth 17, a seeding mechanism 2 and a collection box 3. The first partition 12 is set in the casing 11, and divides the inner cavity of the casing 11 into an installation cavity 110 and a seeding cavity 111. At the bottom of the casing 11, there is a hole that communicates with the seeding cavity 111. At the discharge port, the two cones 15 are hinged on the side wall of the discharge port, and the two cones 15 are connected to the pressure rod 13 through two first connecting rods 16 . The pressure rod 13 is movably inserted in the installation cavity 110, and the upper and lower ends of the pressure rod 13 pass through the side wall of the housing 11 and exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com