Measuring machine based on a delta robot assembly

A technology of robots and measuring machines, which is applied in the field of measuring machines and can solve the problems of reducing the accessibility of measuring volumes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

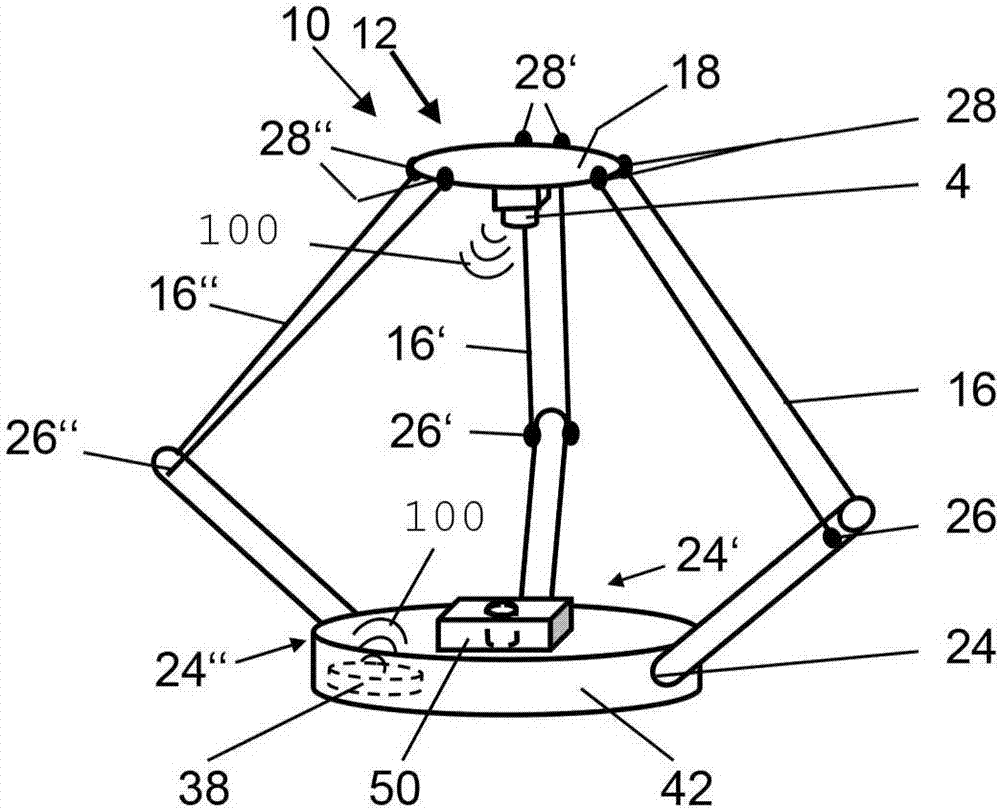

[0035] figure 2 A measuring machine 10 according to the invention is shown with a Delta robot structure 12 . Delta robot structure 12 (also abbreviated as Delta structure 12 ) includes a base plate 42 that supports a workpiece 50 during measurements. In the proposed embodiment the base plate 42 is located at the bottom of the structure for placement on a floor or table in a horizontal orientation. For greater accuracy, the base plate is advantageously provided with clamps (not shown) for securing the workpiece 50 . The three arms 16, 16', 16" of the Delta robotic structure 12 with intermediate joints 26, 26', 26" connect their first ends to the base plate 42 by means of first gimbal joints 24, 24', 24" The arms 16, 16', 16" connect their opposed second ends to the end effector 18 (also referred to as the movable platform 18) by means of a third joint 28, 28', 28", and by means of an actuator ( not shown) is controlled by the control and analysis unit 38. The mobile platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com