Electric pipe climbing device

A tube-climbing, electric technology, applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problem of time-consuming and labor-intensive cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

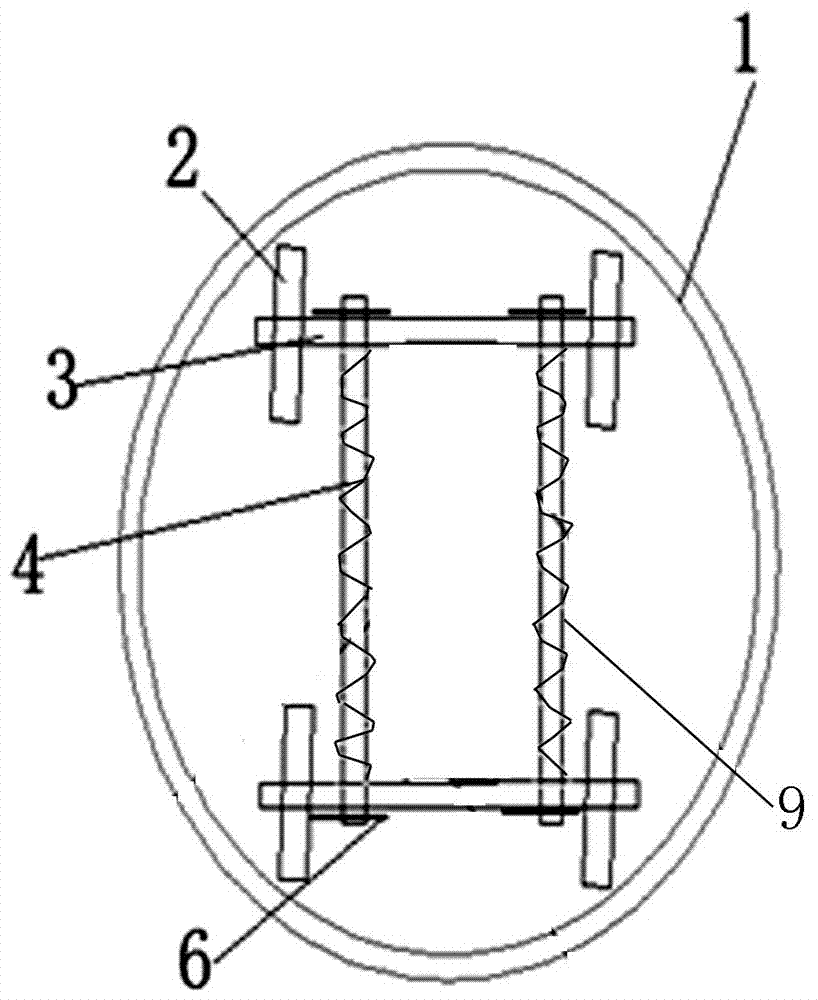

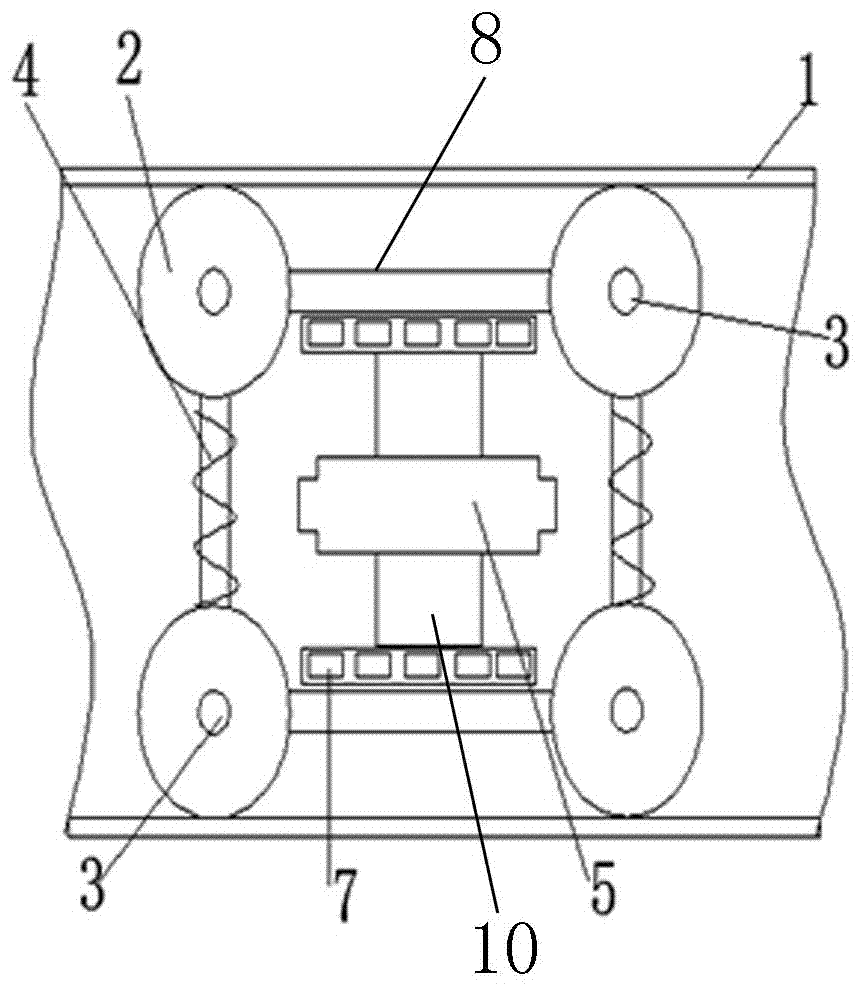

[0015] As shown in the figure, an electric pipe climber includes a brushless hub motor 2, a connecting shaft 3, a transverse connecting rod 8 and a longitudinal connecting rod 9. There are eight brushless hub motors, and two brushless hub motors They are connected by connecting shafts 3, and the four connecting shafts are vertically connected to each other through horizontal connecting rods and longitudinal connecting rods to form a rectangular three-dimensional frame structure; a bracket 10 is arranged between the two upper and lower horizontal connecting rods, and the battery 7 is arranged on the bracket. The battery is connected to the brushless hub motor; the longitudinal connecting rod is slidingly connected to the connecting shaft, and a pin hole is set on the connecting shaft, and the longitudinal connecting rod passes through the pin hole and is positioned by the horizontal pin 6; on the longitudinal connecting rod, there are two A spring 4 is sleeved between the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com