Spinning Mechanism, Method and Application of Gradient Function Spinning with Front Moving Coupling and Wrapping

A functional and translational technology, applied in yarn, textile and paper making, etc., can solve the problems of disorder and fuzziness of fiber arrangement, increase energy consumption and noise, and achieve the effect of overcoming uneven thickness, precise control and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

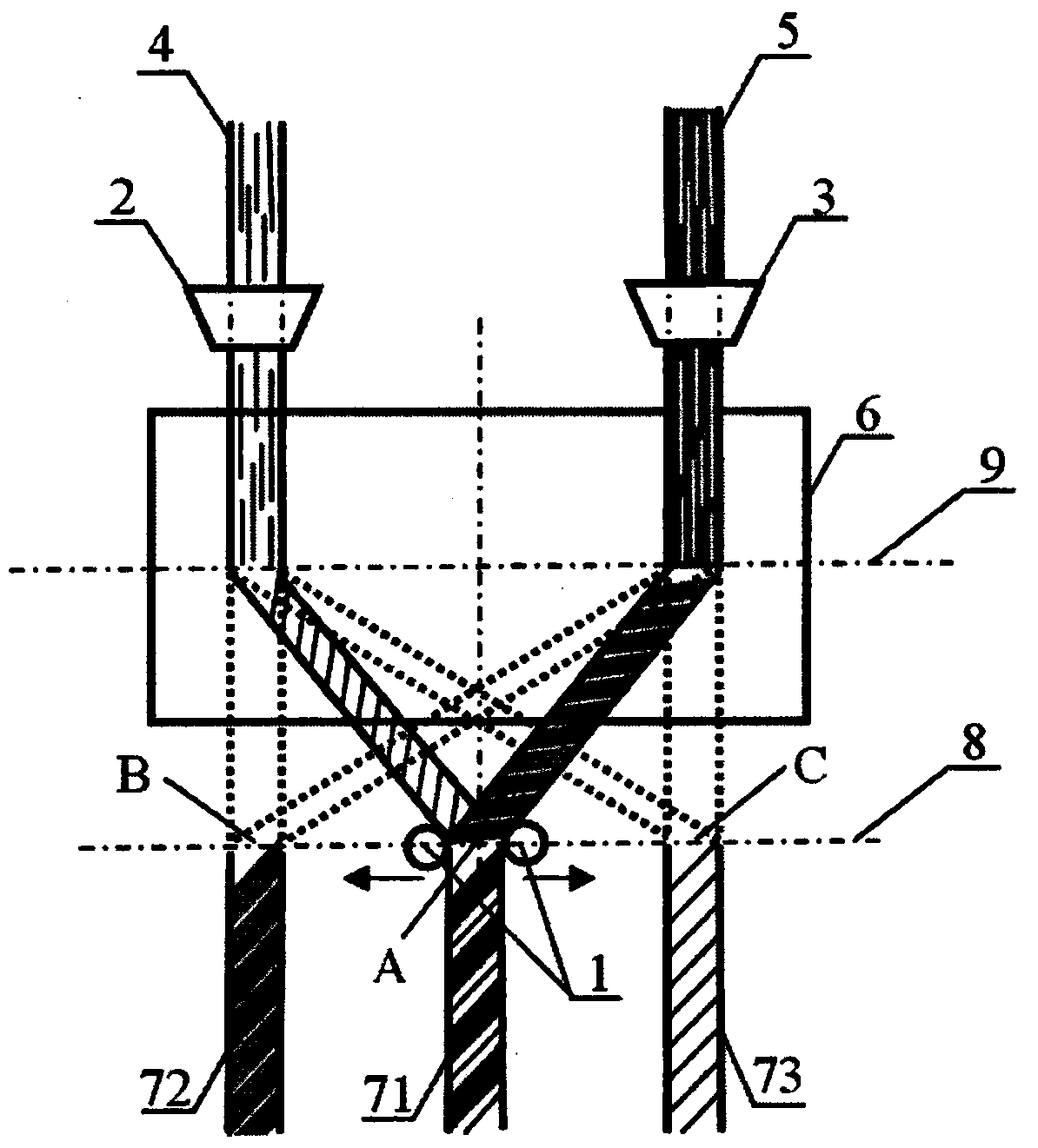

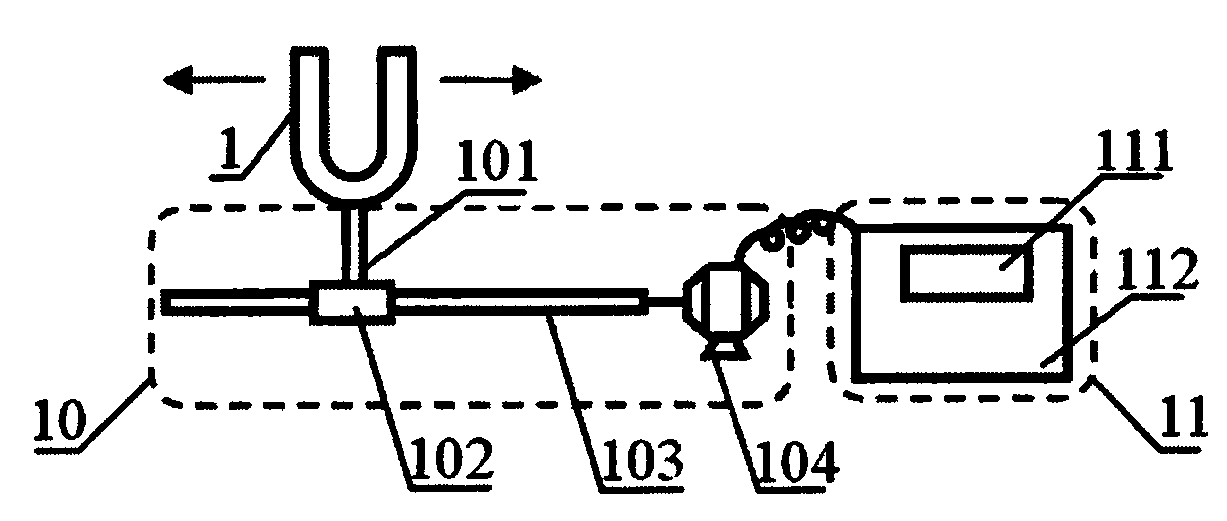

[0054] Take one natural color stainless steel fiber tube and one white cotton fiber tube, and the composite ratio is 50 / 50. After the two bundles of roving are positioned and gathered by the clusterer, they are fed into the nip of the front roller with the natural tension of the drafting and 8mm spacing. For details, see figure 1 shown. After the two-axis fiber strip exits the nip of the front roller, the twist coefficient α tex is 340, and the spindle speed is 10500rpm, it naturally converges at point A, and the convergence angle of convergence point A is about 60°, which is on the center line. Move the U-shaped needle so that the natural convergence point A is located at the center point of the U-shaped needle. A structural functional yarn that is naturally coupled and intertwined at the converging points is formed. Then move the U-shaped needle left and right back and forth with the set yarn gradient function waveform (trapezoidal wave) and wavelength (24m) to make a tra...

Embodiment 2

[0056] Take a gold-plated polyester filament bobbin and a polyester-cotton blended roving bobbin each, and the composite ratio is 50 / 50. After the two bundles of fibers are positioned and gathered by the bundler, they are fed into the nip of the front roller with the natural tension of the drafting and a distance of 10mm. For details, see figure 1 shown. After the two-axis fiber strip exits the nip of the front roller, the twist coefficient a tex is 345, and the spindle speed is 11500rpm and naturally gathers at point A. Move the U-shaped needle so that the natural convergence point A is located at the center point of the U-shaped needle. A structural functional yarn that is naturally coupled and intertwined at the converging points is formed. Then move the U-shaped needle left and right back and forth with the set yarn-forming gradual change function waveform (sine wave) and wavelength (16m) to make a sine wave gradual change, that is, move left to point B with a sine wave...

Embodiment 3

[0058] Take one white polyester yarn bobbin and one white cotton roving bobbin, and the composite ratio is 50 / 50. After the two bundles of fibers are positioned and gathered by the bundler, they are fed into the nip of the front roller with the natural tension of the drafting and a distance of 9mm. For details, see figure 1 shown. After the two-axis fiber strip exits the nip of the front roller, the twist coefficient α tex It is 320, and the spindle speed is 10000rpm and naturally gathers at point A. Move the U-shaped needle so that the natural convergence point A is located at the center point of the U-shaped needle. A structural functional yarn that is naturally coupled and intertwined at the converging points is formed. Then move the U-shaped needle left and right back and forth with the set yarn gradient function waveform (variable frequency triangular wave) and wavelength (64m) to make frequency variable triangular wave gradual change, that is, the variable frequency t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com