Rock field shear strength test device and method

A technology of shear strength and measuring device, which is applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problems of normal force application range regulation, test object damage, and complicated preparation process, so as to avoid shear stress Larger test results, avoid stress instability, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

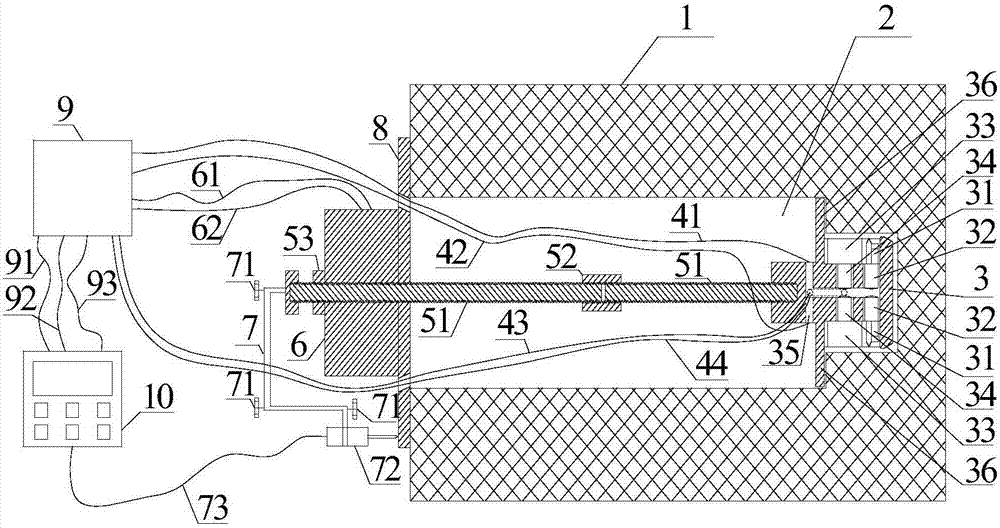

[0049] like figure 1 As shown, the rock in-situ shear strength measurement device includes a shear probe 3 arranged at the bottom of a stepped borehole 2 on the rock 1 to be tested, and the shear probe 3 is provided with a normal force and a shear force loading device, the normal force and shear force loading device includes a plurality of radially arranged oil cylinders arranged in the shear probe 3, and the oil cylinders include a symmetrically arranged shear stress loading plate oil cylinder 32 and a normal force loading plate oil cylinder 34. The shear stress loading plate oil cylinder 32 and the normal force loading plate oil cylinder 34 are connected with a shear probe oil circuit 35, the shear stress loading plate oil cylinder 32 is provided with a shear stress loading plate 31, and the normal force loading plate oil cylinder 34 is provided with a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com