Die mechanism capable of realizing product formation by kiss-off through angle lifters and extraction of angle lifters from undercuts

A technology for products and slanted tops, which is applied in the field of mold mechanisms where slanted tops penetrate products and buckle positions, and can solve problems such as low production efficiency, lack of protection for workers' personal safety, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

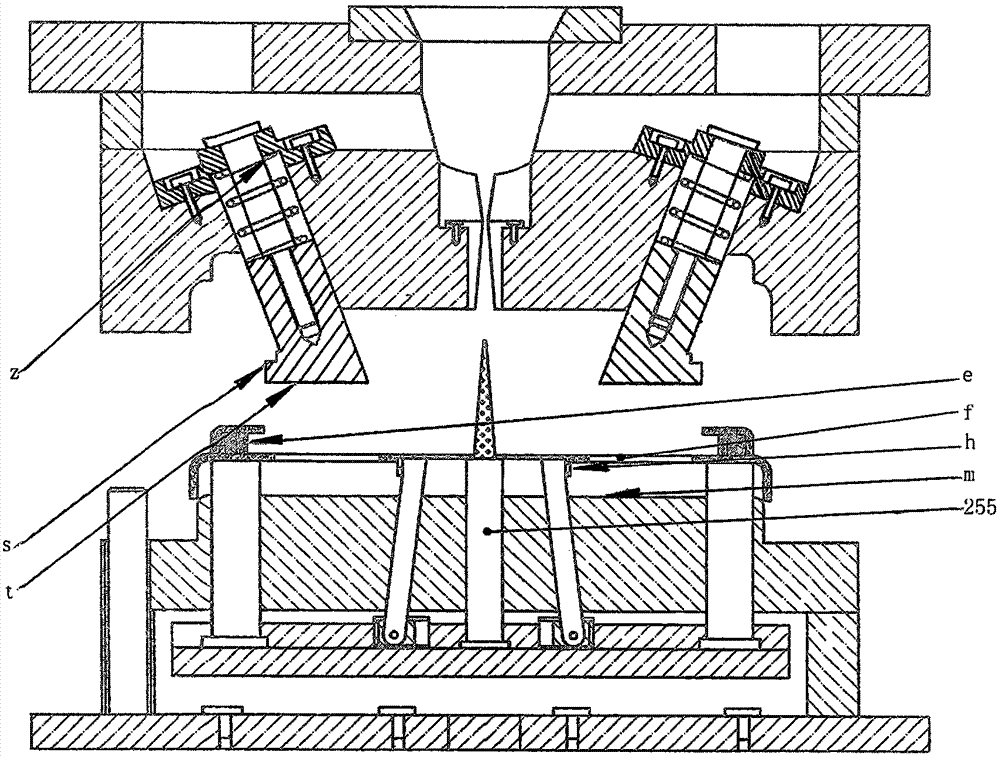

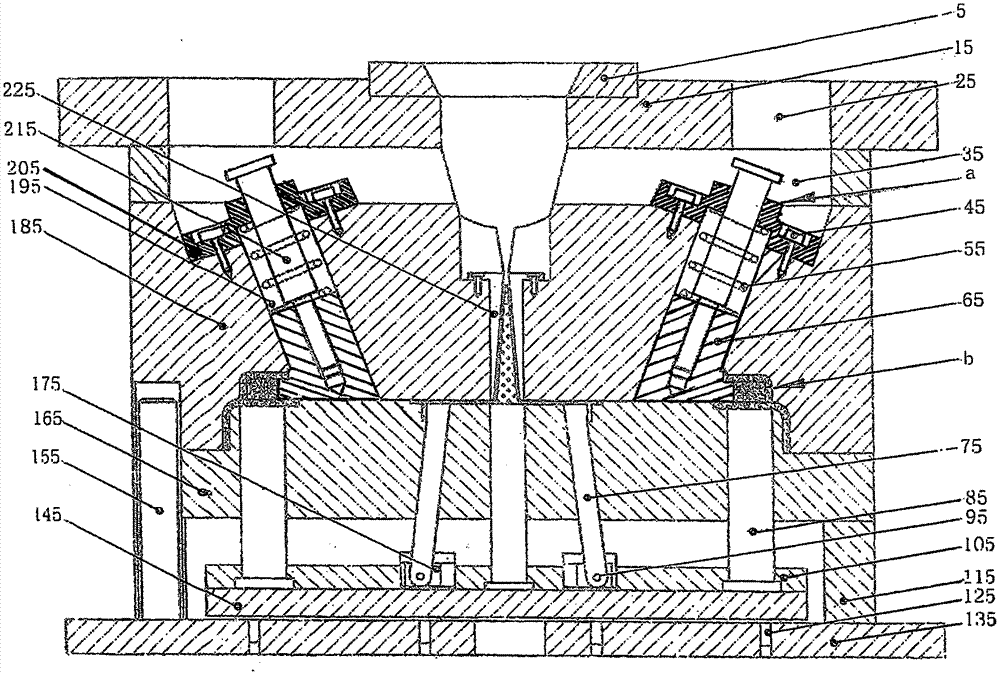

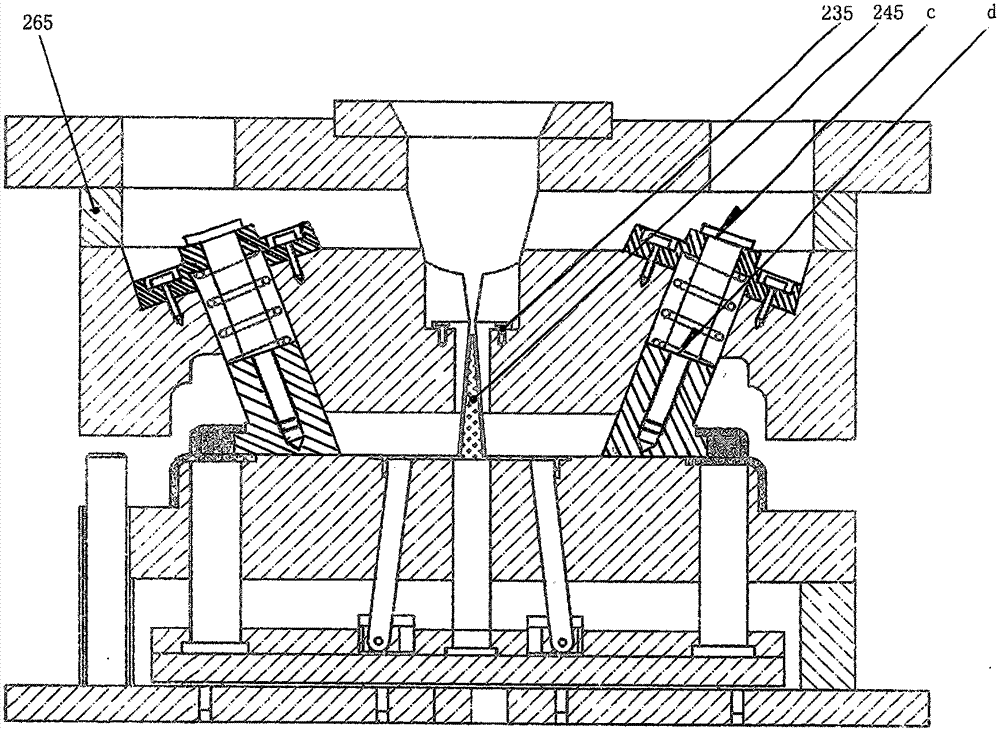

[0032]1. As shown in the figure, the mold structure of the sloped top piercing the product and the buckle position includes a movable mold and a fixed mold, and the fixed mold consists of a positioning ring (5), a fixed mold seat plate (15), and a support plate ( 265), fixed template (185), sprue sleeve (225), first screw (235), second screw (45), limit screw (215), pressure plate (205), spring (55), the Fasten the positioning ring (5) with screws on the fixed mold seat plate (15), the below of the fixed mold seat plate (15) is provided with a support plate (265), and the bottom of the support plate (265) is provided with a fixed template (185), The lower plane of the fixed template (185) is provided with a molding cavity for the molded product b, and guide slide holes (195) are provided on both sides of the fixed template (185), and a fixed guide hole (195) is slidably installed in the guide slide hole (195). Die inclined roof (65), when the front end t of fixed mold inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com