Efficient machine for crushing, decomposing, burying and returning straws

A straw pulverizing and pulverizing mechanism technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of long straw decay cycle, difficulty in sowing, low efficiency, etc., and achieve high straw pulverization efficiency and time consumption. Short, the effect of promoting straw decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

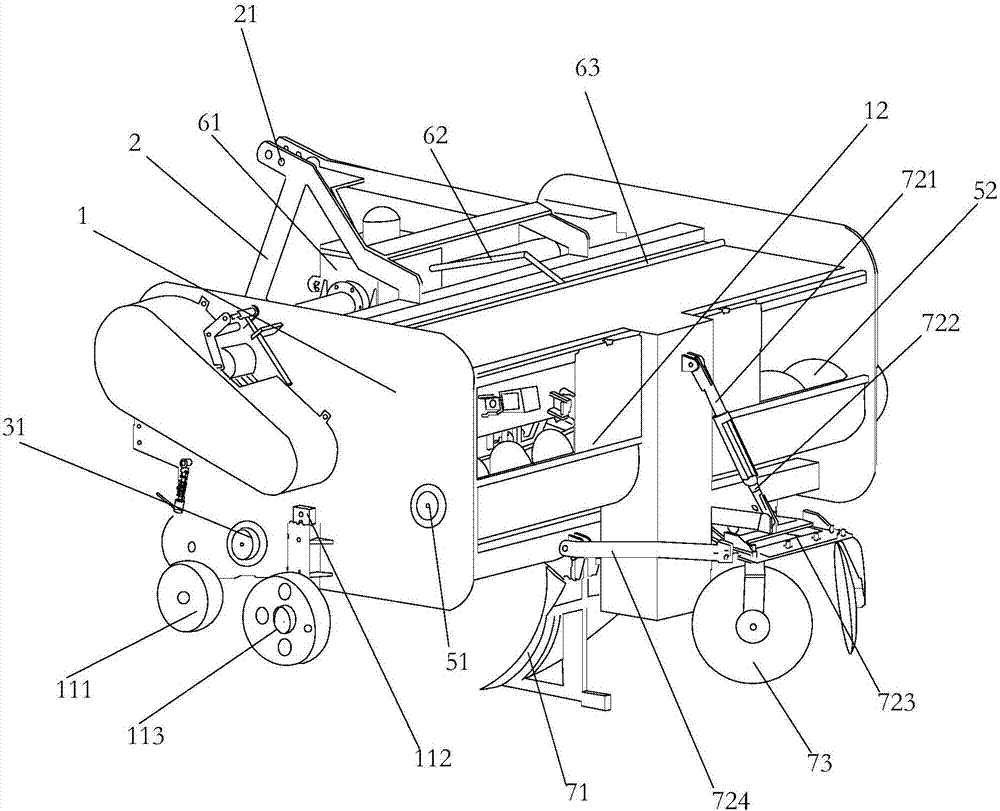

[0021] refer to figure 1 As shown, the present invention proposes a kind of high-efficiency straw crushing, urging, rotting, burying and field returning machine, including a frame 1, a connecting frame 2, a crushing mechanism, a crushed material transmission mechanism, a conveying guide mechanism, a rotting mechanism and a ditching and soil covering mechanism;

[0022] Connecting frame 2 is installed on the frame 1, and connecting frame 2 is provided with a plurality of mounting holes 21, and support device is installed below frame 1;

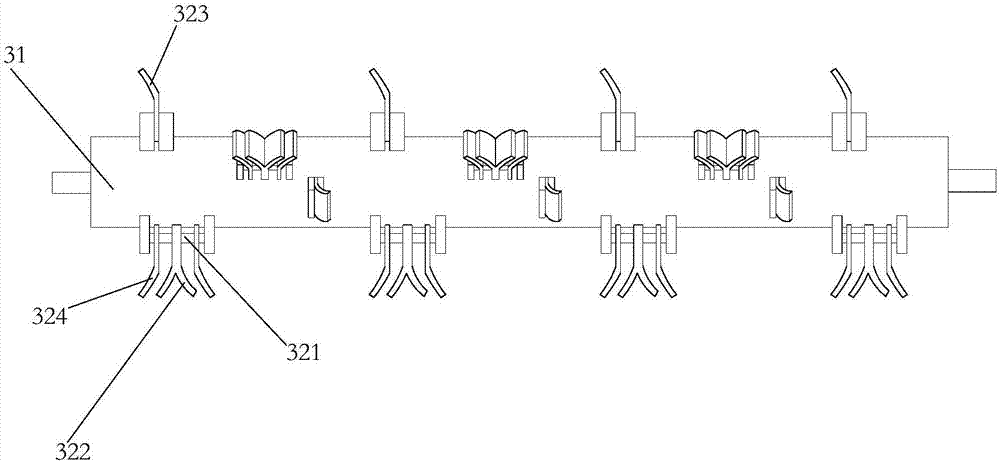

[0023] The crushing mechanism includes an installation shaft 31 and a cutting device, the installation shaft 31 is rotatably mounted on the frame 1, and the cutting device is installed on the installation shaft 31;

[0024] The frame 1 has a material storage tank 12, and the crushed material transmission mechanism is installed between the material storage tank 12 and the crushing mechanism. The conveying guide mechanism includes a first rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Lead | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com