Silicone mold and its manufacturing method

A manufacturing method and silicone technology, applied in the field of mold manufacturing, can solve the problems of low production efficiency, easy deformation of silicone molds, etc., and achieve the effect of ensuring stability, maintaining softness and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

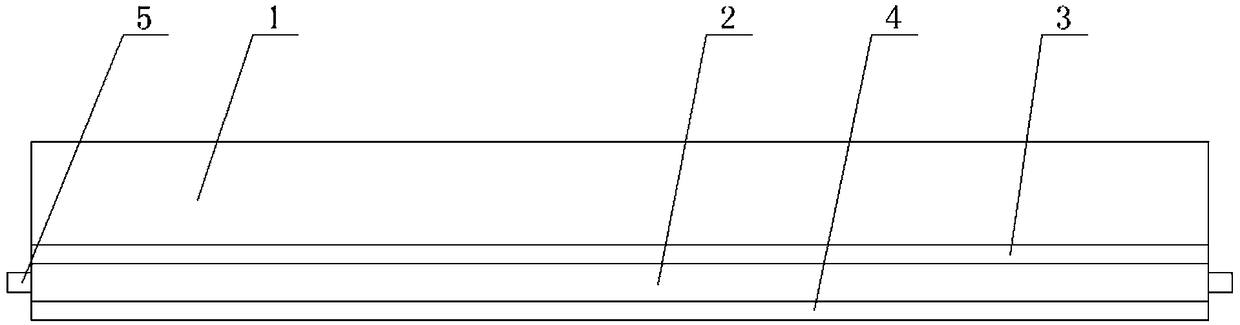

[0023] Such as figure 1 As shown, a silicone mold includes a silicone mold body 1, a Teflon net 2, a first base cloth 3, a second base cloth 4 and a connecting button 5, and the Teflon net 2 is compounded on the bottom of the silicone mold body 1, The first base cloth 3 and the second base cloth 4 are compounded on the top and bottom of the Teflon net 2, and the connecting buckles 5 are fixed on both ends of the Teflon net 2 respectively. Wherein, the first base cloth 3 and the second base cloth 4 are one or more layers; the connecting button 5 and the Teflon net 2 are wrapped with silica gel to prevent the connecting button 5 from being exposed; The silicone mold body 1 is filled with polyurethane particles, which can effectively reduce the weight of the entire silicone mold; the silicone mold body 1 is connected to form a ring through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com