Manufacturing method of efficient biological organic fertilizer

A technology of bio-organic fertilizer and production method, applied in the direction of organic fertilizer, fertilizer made of biological waste, fertilization device, etc., can solve the problems of single organic fertilizer fertility, increase trace element and phosphorus content, inhibit growth, and improve fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

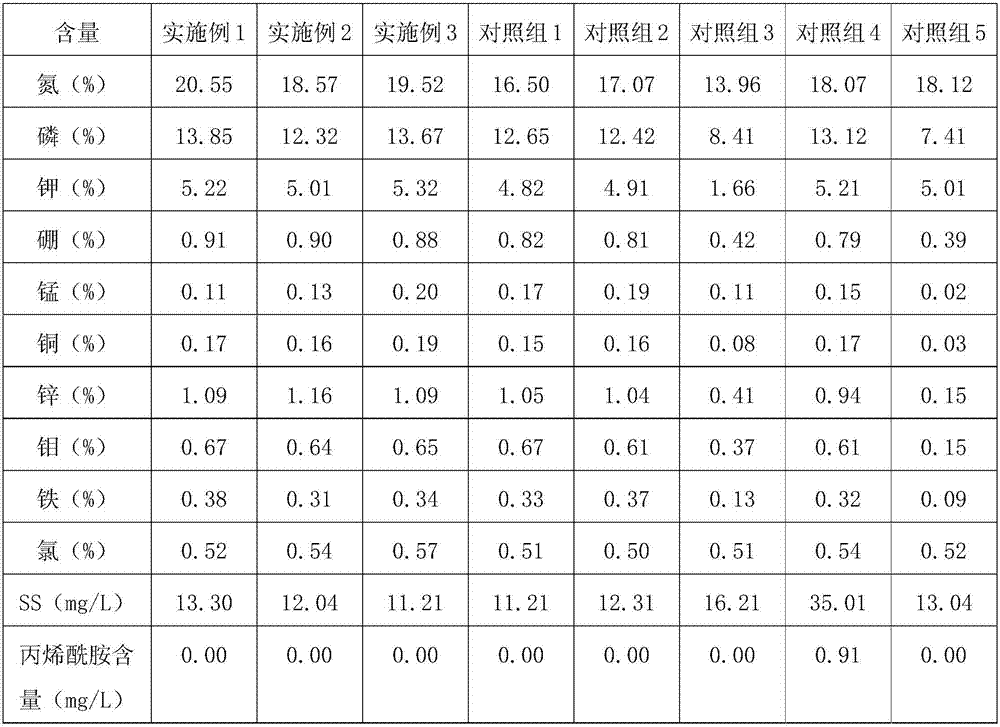

Examples

Embodiment 1

[0029] The preparation method of high-efficiency bio-organic fertilizer comprises the following steps:

[0030] (1) Biogas residue production: put the collected pig manure into the sewage collection tank, and add 2 times the weight of treated water to soak the manure for 12 hours, add an acid-base regulator, and adjust the pH value to 6; then Transfer to the microbial pretreatment tank and add the activated microbial bacterial liquid, add an acid-base regulator, adjust the pH value to 5 to obtain pretreated mixed feces; the added amount of the microbial bacterial liquid is 1 / 1000 of the volume of the pretreated mixed feces ; After the pretreatment mixed manure is processed, it is transferred to the fermentation biogas tank for fermentation. The fermentation temperature is 28 °C and the fermentation time is 48 hours. The remaining fermentation product is filtered and pressed until the moisture content is 40% to obtain biogas residue;

[0031] (2) Secondary sedimentation: impor...

Embodiment 2

[0047] The preparation method of high-efficiency bio-organic fertilizer comprises the following steps:

[0048] (1) Biogas residue production: put the collected pig manure in the sewage collection tank, and add 3 times the weight of treated water to soak the manure for 18 hours, add an acid-base regulator, and adjust the pH value to 8; then Transfer to the microbial pretreatment tank and add the activated microbial bacterial liquid, add an acid-base regulator, adjust the pH value to 7 to obtain pretreated mixed feces; the amount of microbial bacterial liquid added is 1 / 1500 of the volume of the pretreated mixed feces ;After the pretreatment mixed manure is processed, it is transferred to the fermentation biogas tank for fermentation. The fermentation temperature is 32°C and the fermentation time is 50h. The remaining fermentation products are filtered and pressed until the moisture content is 50% to obtain biogas residue;

[0049] (2) Secondary sedimentation: import the bioga...

Embodiment 3

[0065] The preparation method of high-efficiency bio-organic fertilizer comprises the following steps:

[0066] (1) Biogas residue production: put the collected pig manure in the sewage collection tank, and add 2.5 times the weight of treated water to soak the manure for 14 hours, add an acid-base regulator, and adjust the pH value to 7; then Transfer to the microbial pretreatment tank and add the activated microbial bacterial liquid, add an acid-base regulator, adjust the pH value to 6 to obtain pretreated mixed feces; the amount of the microbial bacterial liquid added is 1 / 1200 of the volume of the pretreated mixed feces ; After the pretreatment mixed manure is processed, it is transferred to the fermentation biogas tank for fermentation. The fermentation temperature is 30°C and the fermentation time is 49 hours. The remaining fermentation product is filtered and pressed until the moisture content is 45% to obtain biogas residue;

[0067] (2) Secondary sedimentation: import...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com