Rotating joint with hydraulic self-locking function

A rotary joint and self-locking technology, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of high cost, complex structure of oil cylinder, low safety and reliability, and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

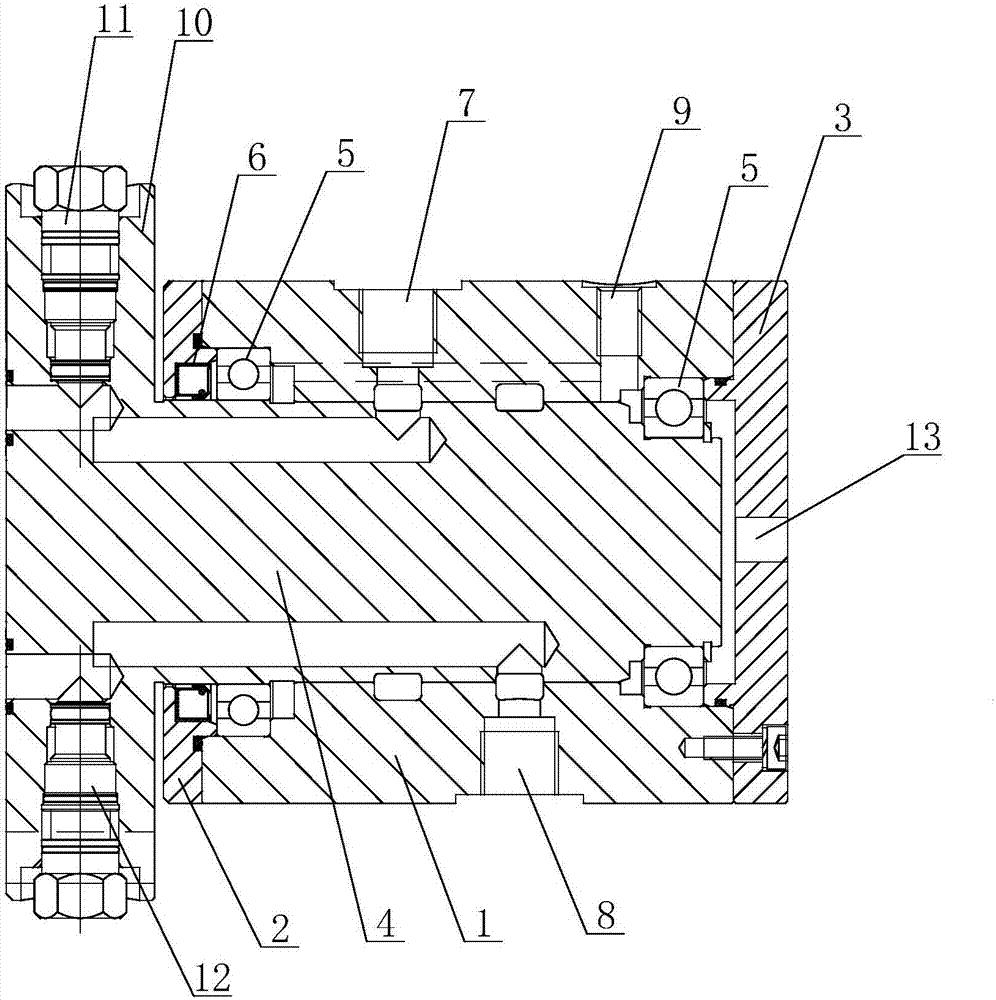

[0017] see figure 1 as shown, figure 1 It is a schematic structural diagram of a rotary joint with hydraulic self-locking function provided in Embodiment 1 of the present invention.

[0018] In this embodiment, a rotary joint with a hydraulic self-locking function includes a housing 1, an end cover 2, a tail cover 3 and a rotating shaft 4, and the two ends of the housing 1 are respectively installed with the end cover 2 and the tail cover 3, so that The rotating shaft 4 is rotatably arranged in the housing 1 , and bearings 5 are provided between both ends and the housing 1 , and rotating lip seals 6 are provided between the end cover 2 and the rotating shaft 4 .

[0019] The housing 1 is provided with a first oil port 7, a second oil port 8 and an oil drain port 9, the outer end of the rotating shaft 4 is provided with a mounting flange 10, and the mounting flange 10 is provided with a second A hydraulically controlled one-way valve 11 and a second hydraulically controlled...

Embodiment 2

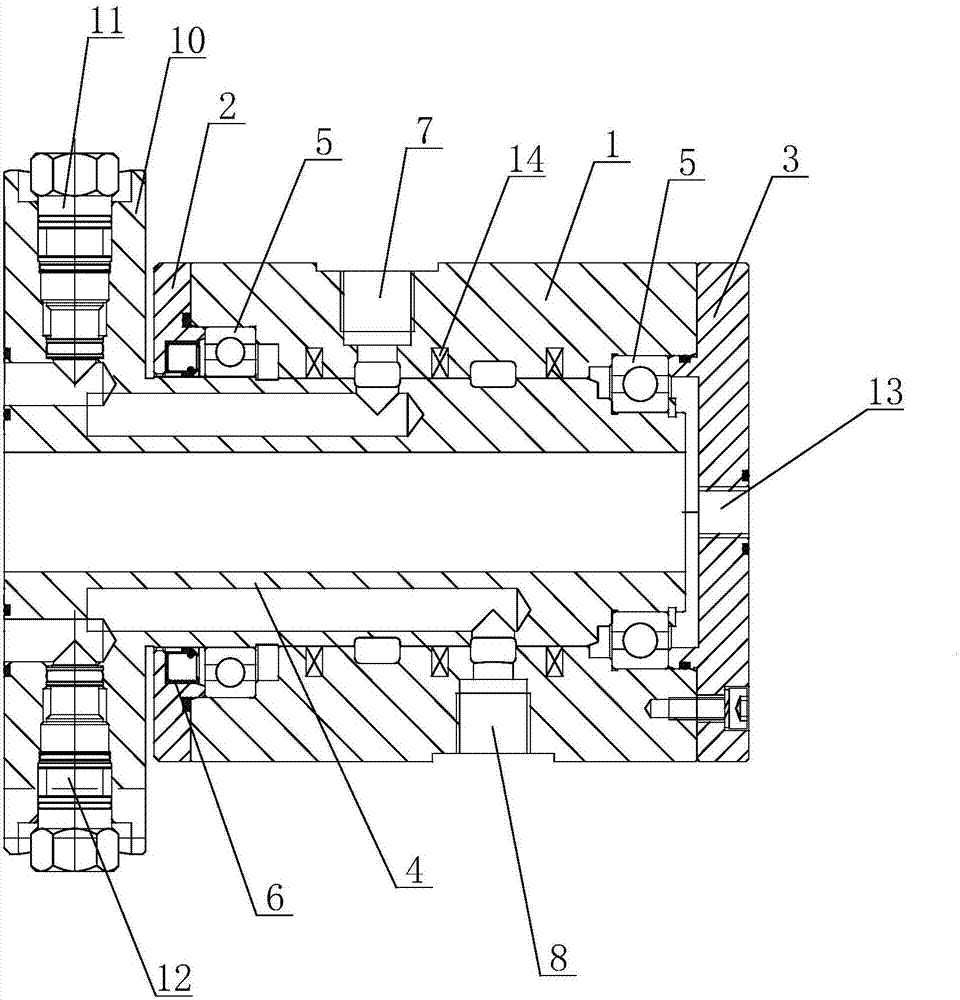

[0023] see figure 2 as shown, figure 2 It is a schematic structural diagram of a rotary joint with hydraulic self-locking function provided by Embodiment 2 of the present invention.

[0024] The main difference between this embodiment and Embodiment 1 is that the sealing form between the rotating shaft 4 and the housing 1 is different. In this embodiment, several high-pressure channels are arranged between the rotating shaft 4 and the housing 1. sealing ring 14. The sealing of the hydraulic oil is realized by the high-pressure sealing ring 14 . At the same time, only the first oil port 7 and the second oil port 8 are opened on the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com