Bonding area ratio peeling test method for thermal insulation materials on the basis of image processing technology

A technology of thermal insulation materials and bonding area, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as easy counting errors, long time-consuming small square counting process, fatigue, etc., achieve high precision, ensure safe construction, and solve Checking Difficult Effects

Active Publication Date: 2017-07-14

KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

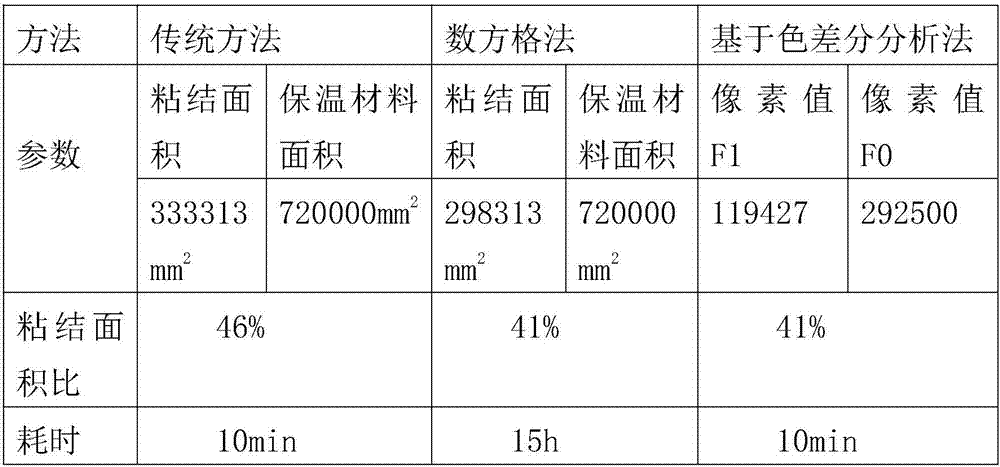

[0004] In order to improve the accuracy, the small grids of graph paper are used to measure, and the irregular adhesive mortar is subdivided into grids, and then the area of the adhesive mortar is counted by counting the small grid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

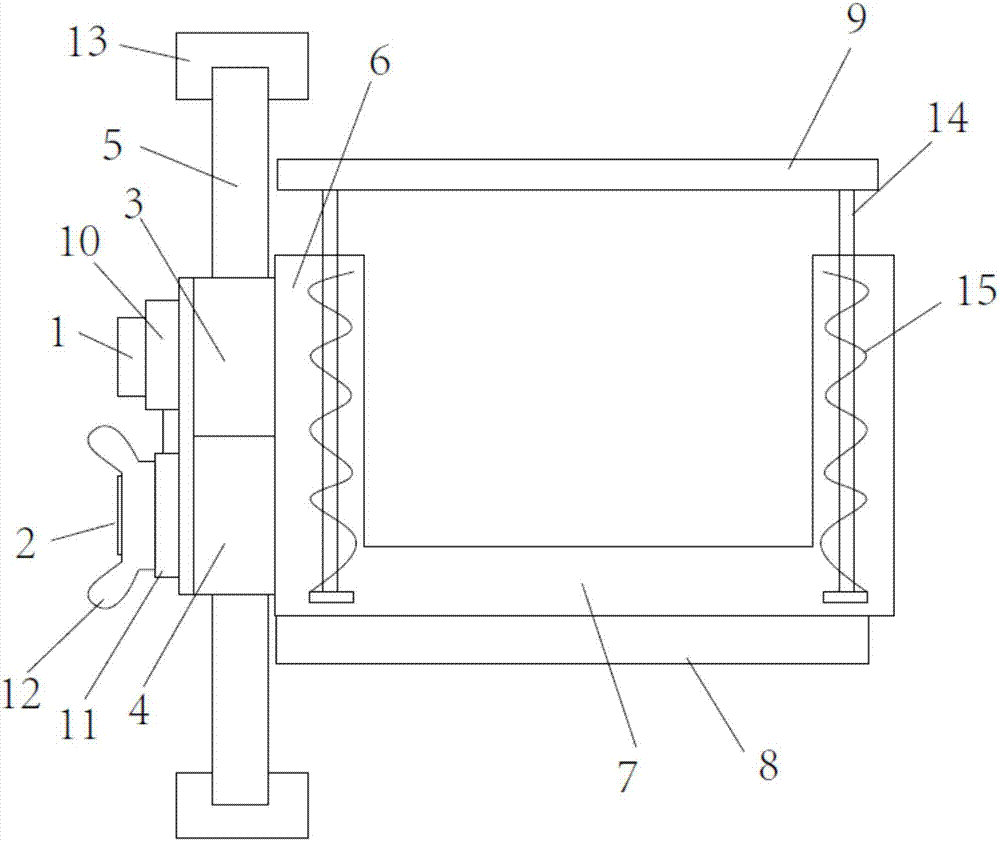

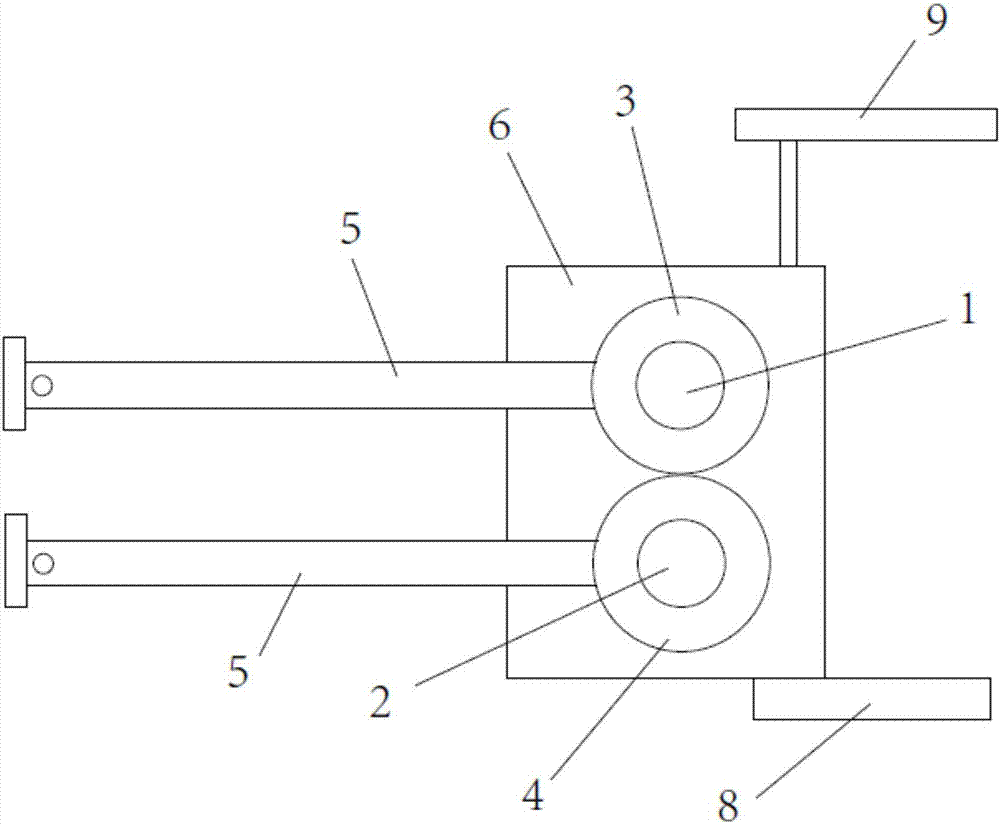

The invention discloses a bonding area ratio peeling test method for thermal insulation materials on the basis of an image processing technology. The test method includes the steps as follows: 1) peeling a thermal insulation board; 2) determining solid adhesion or false adhesion; 3) line drawing: drawing external frame lines of a thermal insulation material on a base wall body with a red marking pen, and then drawing an external bounding line of every area of bonding mortar, if the bonding mortar, peeled with the thermal insulation material, belongs to the solid adhesion part after determination, complementing the external bounding lines during the line drawing; and 4) photographing the base wall body at the sampled positions; and 5) image processing: calculating a first pixel, which is the area corresponding to interior of the external bounding lines, and a second pixel, which is the total area of the bonding mortar parts in the external bounding lines, through image processing software; and 6) calculating the ratio of area. The method can quickly and accurately calculate the area ratio of bonding area of the external wall thermal insulation material, and has excellent applicability and reliability.

Description

technical field [0001] The invention relates to the field of construction, in particular to a peeling test method for the bonded area ratio of thermal insulation materials based on image processing technology. Background technique [0002] As an important part of the wall energy-saving project, the insulation material has a direct impact on the energy-saving effect of the wall due to its construction quality and reliability. GB 50411-2007 "Code for Construction Quality Acceptance of Building Energy-saving Engineering" requires that the bonding or connection between the insulation material and the base layer and each structural layer must be firm, the bond strength should meet the design requirements, and the bond strength between the insulation board and the base layer should be On-site pull-out test. Afterwards, it is verified by engineering practice that only the on-site pull-out test is used to check whether the bond strength meets the standard at the position where the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N19/04

CPCG01N19/04

Inventor 陈可君顾盛唐军张军

Owner KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com