Method and device for controlling cleaning brush roller

A technology for cleaning brushes and brush rollers, which is applied in the coating, metal material coating process, hot-dip coating process, etc., and can solve the problems of poor strip cleaning quality and strip quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

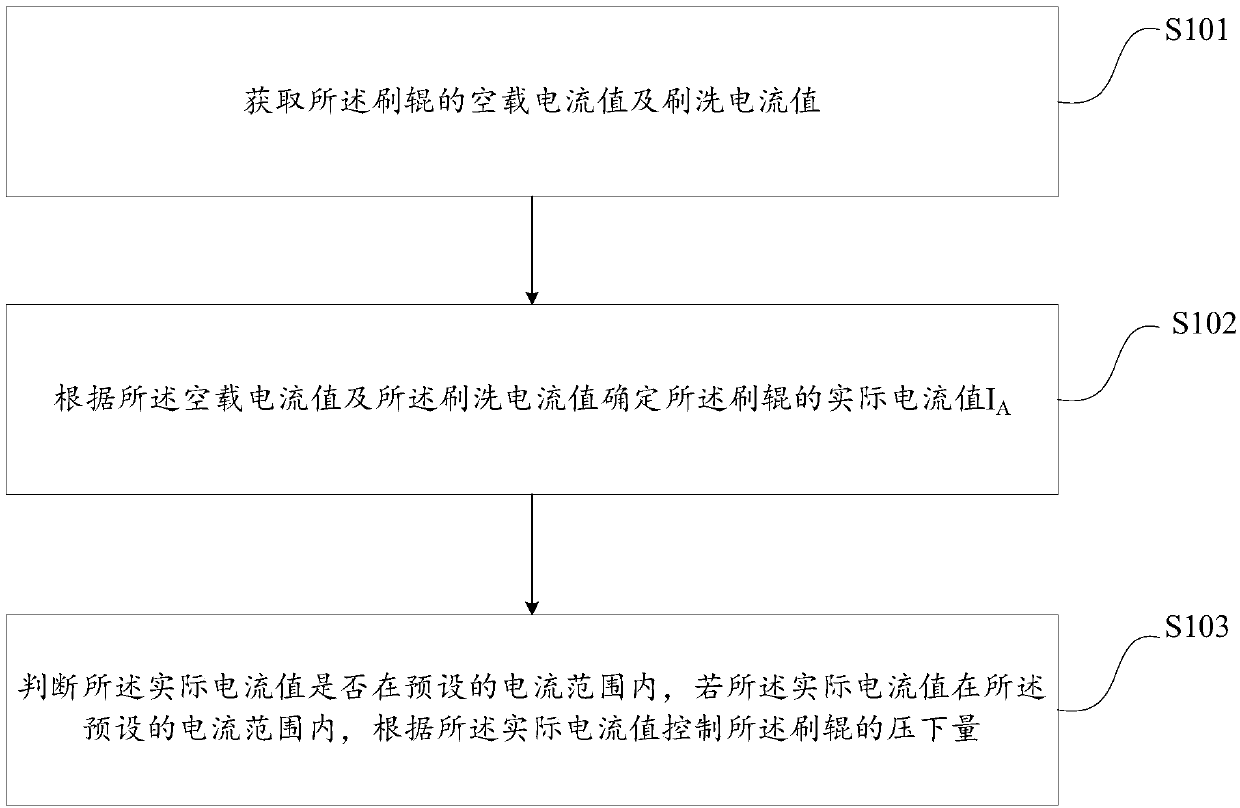

[0030] This embodiment provides a method for controlling cleaning brush rolls, such as figure 1 As shown, the method includes:

[0031] S101. Obtain the no-load current value and brushing current value of the brush roller.

[0032] In this step, in order to avoid the impact of the change of the diameter of the brush roller on the current control, it is necessary to obtain the no-load current value and the brushing current value of the brush roller. In this step, the control current of the brush roller is divided into no-load current and brushing current. Current; the no-load current refers to the current value when the brush roller does not touch the strip steel when it is running stably, and the said over-brushing current value is the increase in current when the brush roller has a scrubbing effect on the strip steel after touching the strip steel value. Wherein, the brushing current value can be determined in advance through production experience.

[0033] S102. Determine...

Embodiment 2

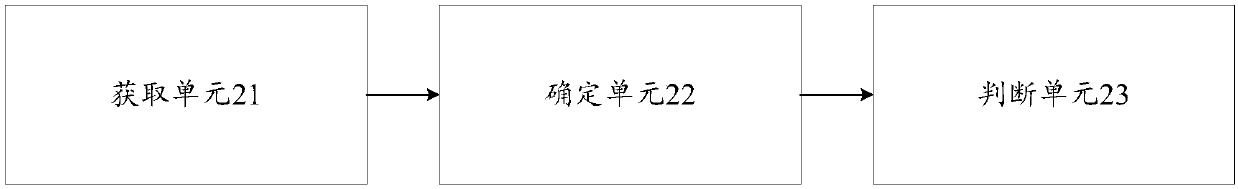

[0050] Corresponding to Embodiment 1, this embodiment also provides a device for controlling cleaning brush rollers, such as figure 2 As shown, the device includes: an acquisition unit 21, a determination unit 22, and a judgment unit 23; wherein,

[0051] The acquisition unit 21 is used to acquire the no-load current value of the brush roller and the brushing current value of the brush roller; in order to avoid the influence of the change of the diameter of the brush roller on the current control, the acquisition unit 21 needs to acquire the The no-load current value and the brushing current value of the brush roller are described. In this embodiment, the control current of the brush roller is divided into no-load current and brushing current; The current value, the said over-brushing current value is the increase value of the current when the brush roller has a scrubbing effect on the strip steel after touching the strip steel. Wherein, the brushing current value can be det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com