Dual-channel coaxial rotary joint

A rotary joint and dual-channel technology, applied to circuits, waveguide devices, electrical components, etc., can solve problems such as large size, unstable performance, and narrow frequency range of waveguide channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

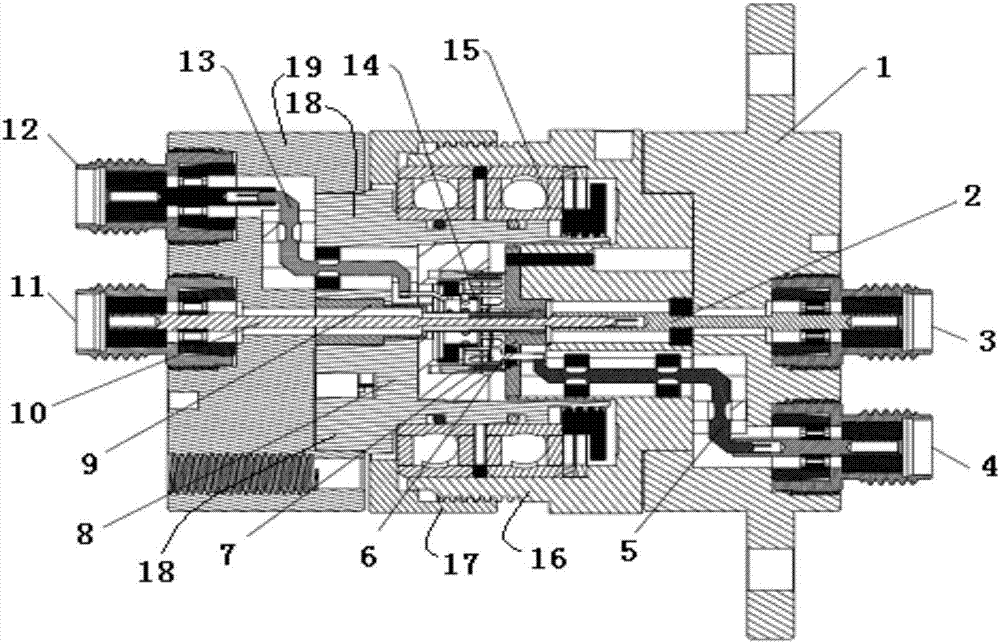

[0019] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0020] figure 1 It is a structural schematic diagram of a dual-channel coaxial rotary joint implementing the present invention. Such as figure 1 As shown, a double-channel coaxial rotary joint includes a rotating end 19 and a fixed end, the fixed end includes a flange 1, and the outer end surface of the flange 1 is provided with a first channel fixed end interface 3 and The second channel fixed end interface 4, the inner end surface of the flange 1 is fixedly connected with the bearing seat 16, the bearing 15 is installed in the bearing seat 16, the bearing 15 is connected with the rotating body 8, and the rotating body 8 Connect the rotating end 19, the outer end surface of the rotating end 19 is provided with a first channel rotating end interface 11 and a second channel rotating end interface 12, and the first channel rotating end interface 11 is provided with a first channel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap