Method Of Operating Switched Reluctance Machine

A technology of switched reluctance motor and switched reluctance drive, which is applied in the direction of single reluctance motor starter, motor control, motor generator test, etc., and can solve the problems of impossible monitoring system insulation, magnetic flux reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

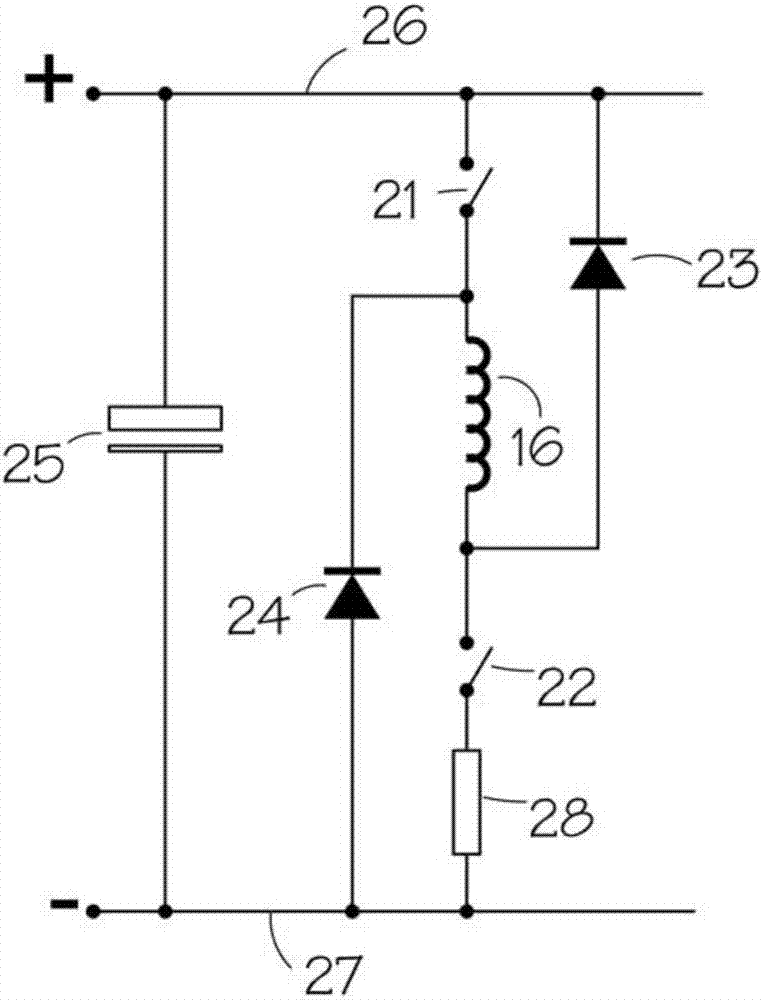

[0031] Figure 5 shows a typical energization scheme for single pulse operation of a switched reluctance motor as described in the Stephenson and Blake paper above. By closing both switches 21, 22, the predetermined rotor angle θ shown in Fig. 5(b) on Apply the DC link voltage. at conduction angle θ c During the application operation continues until the turn-off angle θ off , at the turn-off angle θ off The switch is turned off and the current flows through diodes 23, 24 back to the DC link. During this period of decaying current, energy is returned to the DC link. Although the current in the phase winding is unidirectional, as shown in Fig. 5(b), the current in the DC link is bidirectional. The current continues to decay until the diodes 23, 24 become reverse biased and the current is at θ idle stop. Then there is a period, as shown in Figure 5(b), during which no current flows and the winding is isolated from the DC link.

[0032] Figure 6 shows the corresponding oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com