Automatic film pasting device

A film sticking device and automatic technology, which is applied in packaging and other directions, can solve the problems of crooked sticking, long time-consuming film sticking, and easy existence of air bubbles, etc., and achieves the effect of simple device structure, good film sticking effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

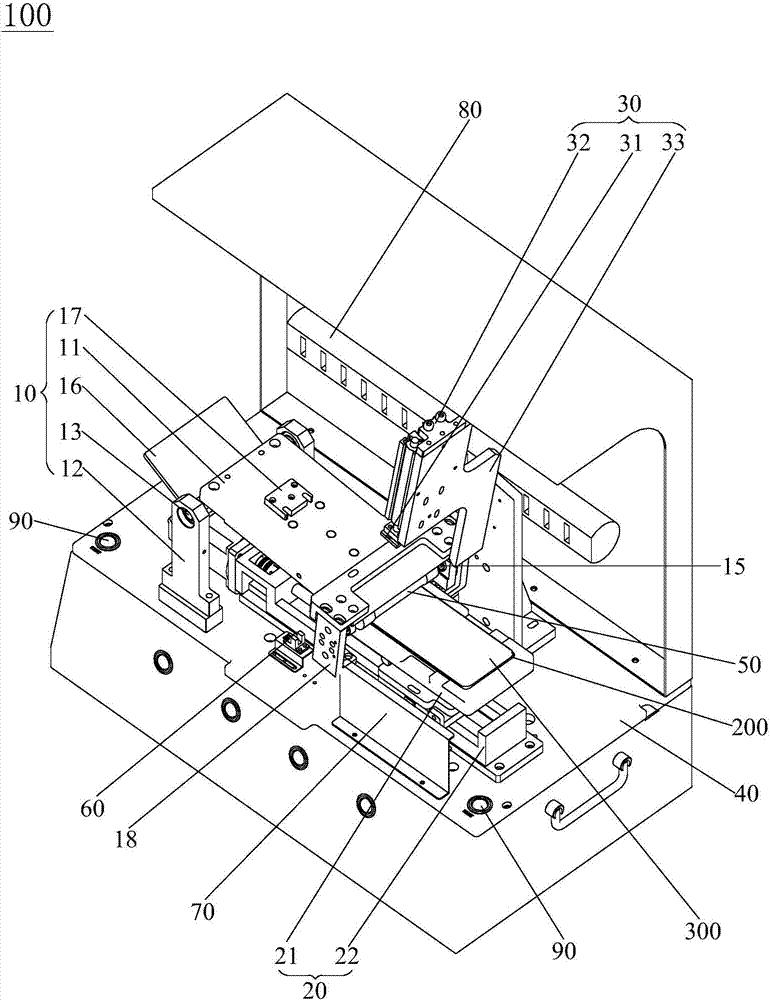

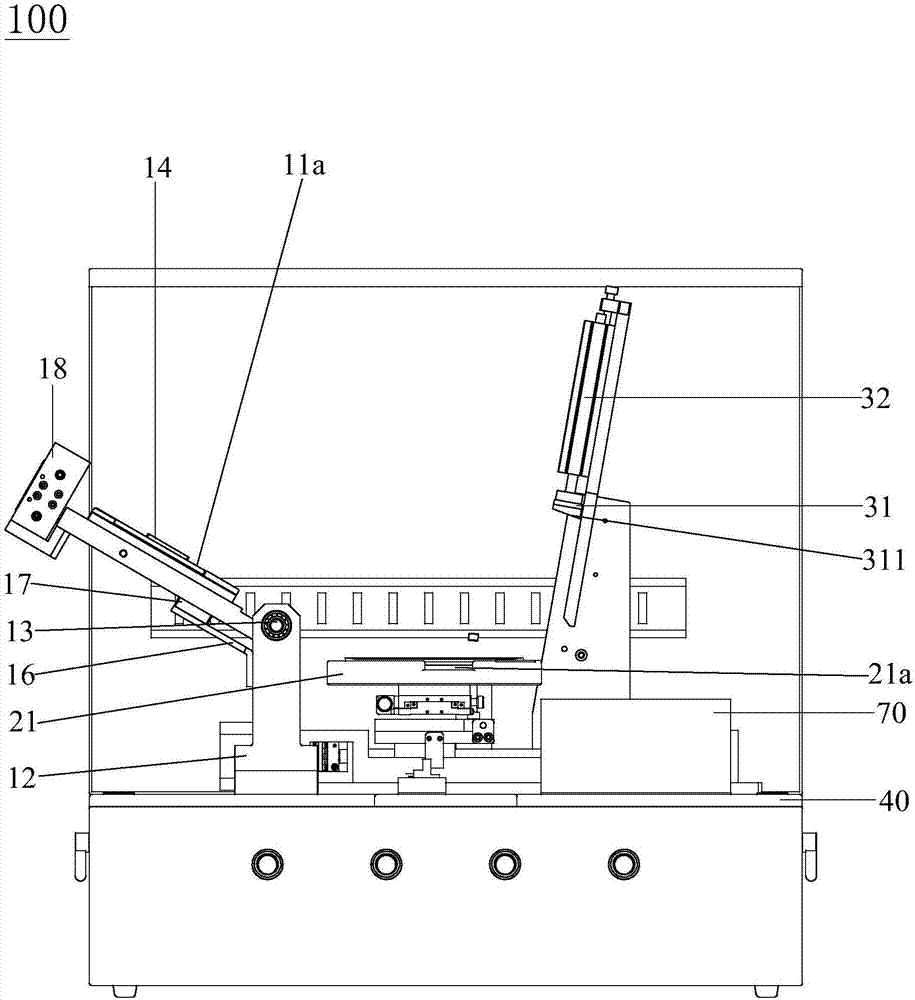

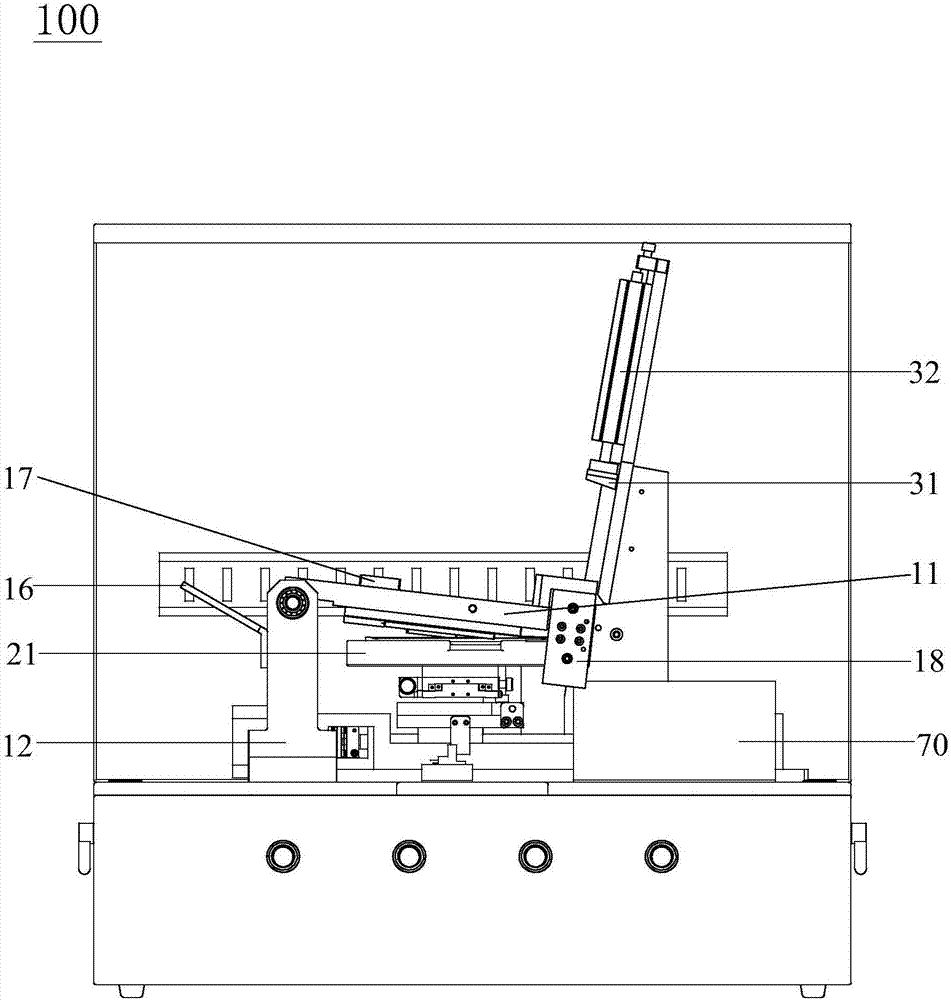

[0021] see Figure 1 to Figure 4 , the present invention discloses an automatic film sticking device 100, which is used for sticking a protective film 300 on the screen 200 of electronic products such as mobile phones and tablet computers. The shape of the screen 200 of electronic products can be flat or curved. The automatic film sticking device 100 of the present invention is suitable for electrical connection with a controller (not shown in the figure), and the controller controls the actions of various parts of the present invention to further improve the degree of automation of the automatic film sticking device 100, wherein the controller is the present invention. Some controllers, whose structures and control principles are well kno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com