Automatic push type loading container for freezer

An automatic propulsion and propeller technology, applied in applications, home appliances, display cabinets, etc., can solve the problem of the way the frozen products are placed affecting the taste of the products, and achieve easy installation and replacement of parts, avoid space waste, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

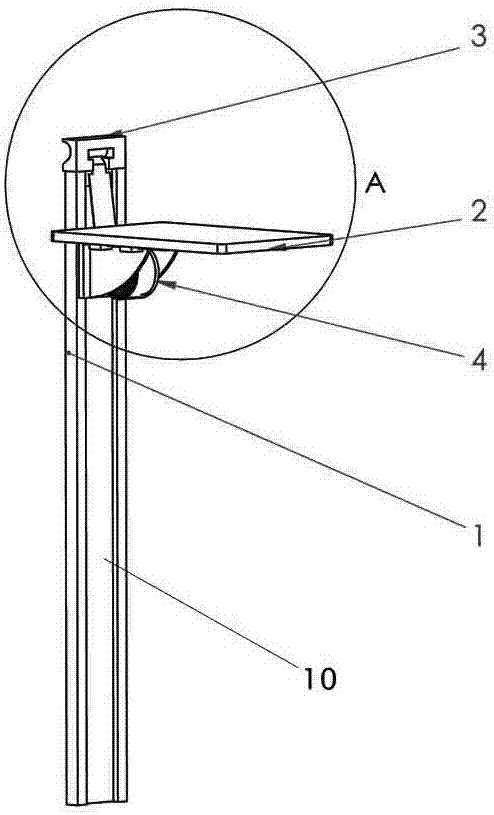

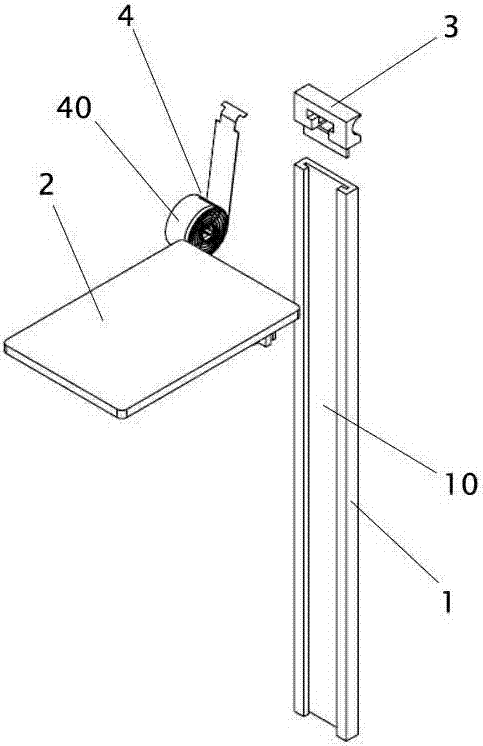

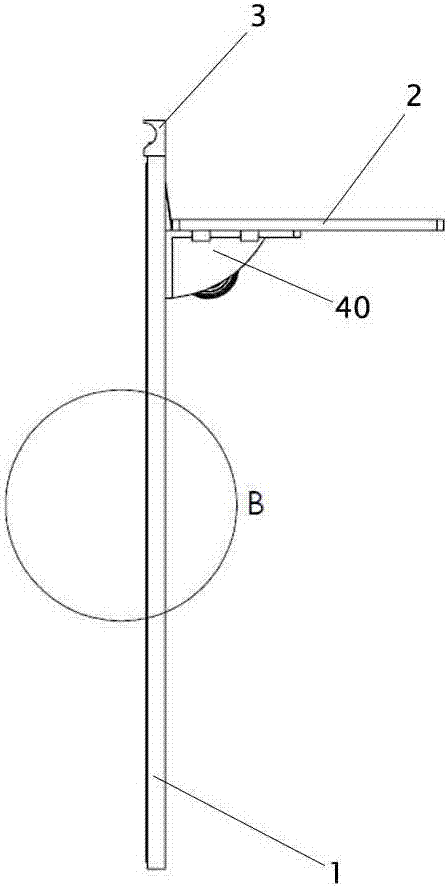

[0025] The present invention will be further illustrated in conjunction with the following examples.

[0026] refer to Figure 4 , a loading container for a self-propelled freezer, comprising a container body 303 and a propeller disposed in the container body 303 .

[0027] refer to Figure 7 and Figure 8 , the container body 303 is a cubic container without a top cover that can and can only accommodate a row of boxed frozen products arranged vertically. The container body 303 is made of durable plastic, and each container body 303 includes a supporting portion and an enclosing portion integrally connected. Wherein the supporting part is made up of a square bottom panel 305 and three side baffles 304 which are vertically connected to three sides of the bottom panel 305 respectively. The product provides a storage port. The enclosing portion is composed of a square bottom cover plate 307 and two side cover plates 306 vertically connected to the two adjacent sides of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com