Adjustable strain-sensing high polymer with hybridized nano conducting material

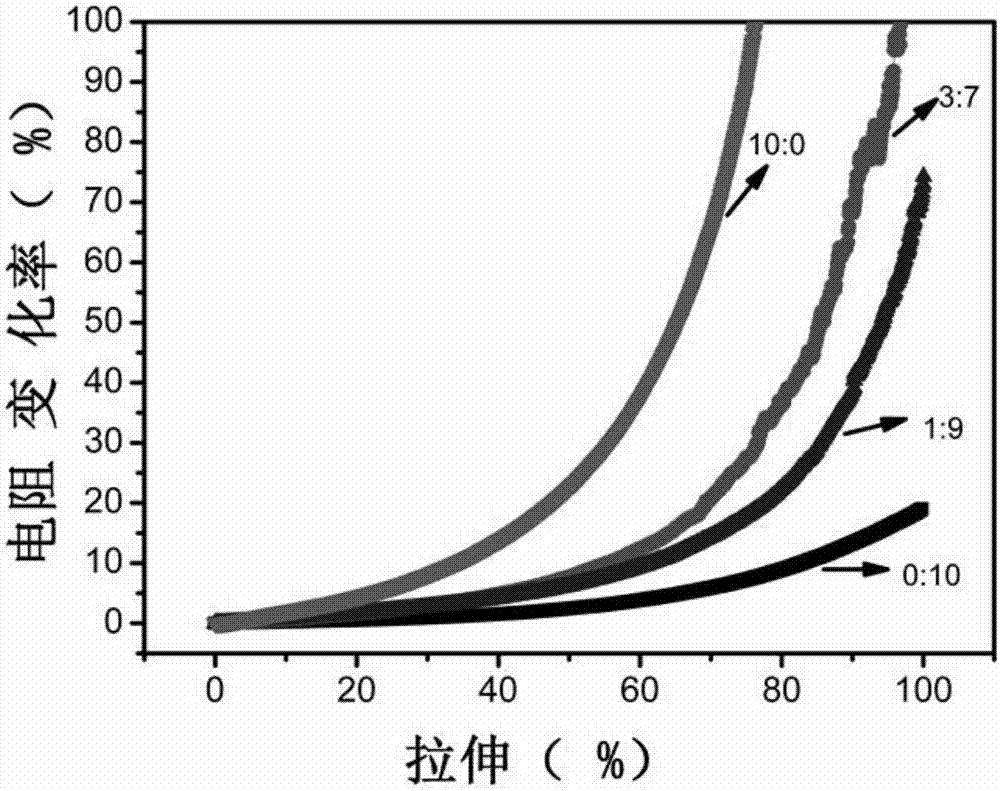

A nano-conductive and strain-sensing technology, which is applied in the field of nano-conductive materials and polymer composite materials, can solve the problems of irreversible strain response range, conductivity instability, conductive network is easy to be destroyed, etc., to improve ductility and Reversible, adjustable sensitivity, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

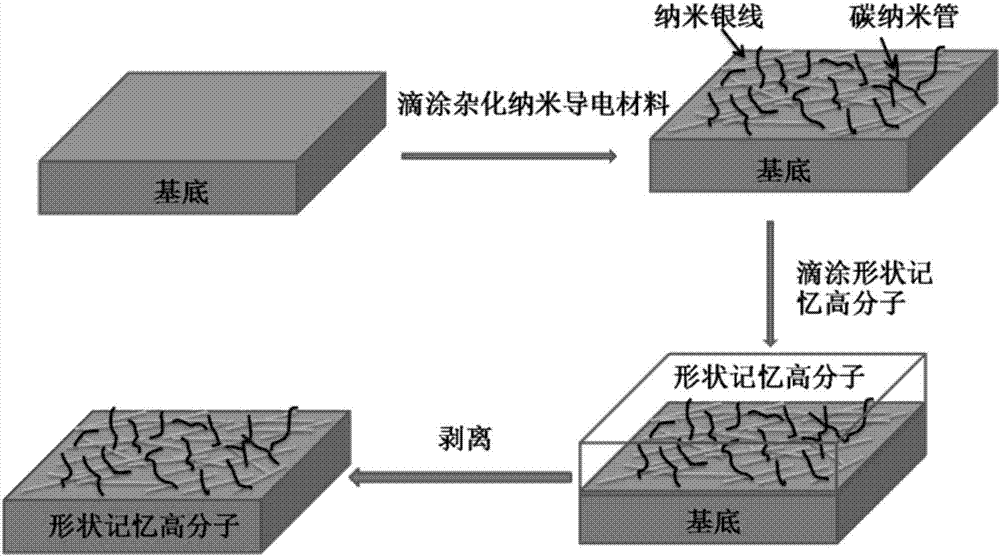

[0041] An adjustable strain-sensing polymer with a hybrid nano-conductive material, mainly composed of the following components by weight: 1 part of a hybrid nano-conductive material and 99 parts of a shape-memory polymer base material, the hybrid nano Conductive materials include metal nanowires and nanocarbon materials.

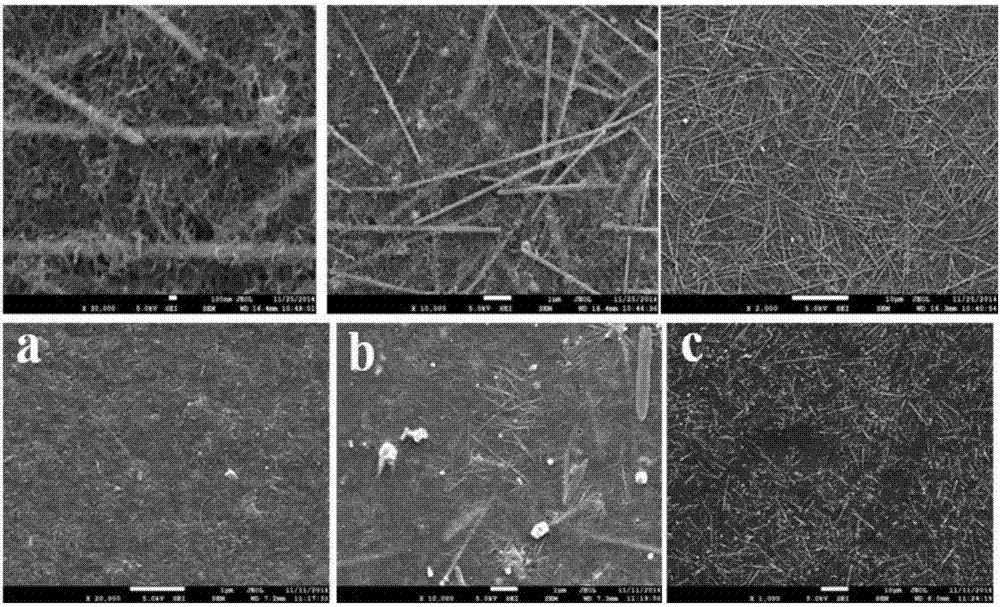

[0042] In the specific technical solution of the present invention, the metal nanowires are silver nanowires, the wire length of the metal nanowires is 20 μm, and the diameter is 60 nm, and the nano-carbon materials are multi-walled carbon nanotubes and single-walled carbon nanowires. For carbon nanotubes, the metal nanowire accounts for 5% by mass of the hybrid nanoconductive material, and the nanocarbon material accounts for 95% by mass of the hybrid nanoconductive material.

[0043] In the specific technical solution of the present invention, the thickness of the hybrid nano conductive material is 10 μm, the shape memory polymer base material is high ela...

Embodiment 2

[0050] An adjustable strain-sensing polymer with a hybrid nano-conductive material, mainly composed of the following components by weight: 5 parts of a hybrid nano-conductive material and 95 parts of a shape-memory polymer base material, the hybrid nano Conductive materials include metal nanowires and nanocarbon materials.

[0051] In the specific technical solution of the present invention, the metal nanowires are copper nanowires, the wire length of the copper nanowires is 30 μm, and the diameter is 70 nm, the nanocarbon material is graphene oxide, and the copper nanowires account for The mass percentage of the hybrid nano conductive material is 30%, and the mass percentage of the graphene oxide in the hybrid nano conductive material is 70%.

[0052] In the specific technical solution of the present invention, the thickness of the hybrid nano conductive material is 20 μm, the shape memory polymer base material is polyester, the mass range of the shape memory polymer base mat...

Embodiment 3

[0059] An adjustable strain-sensing polymer with a hybrid nano-conductive material, mainly composed of the following components by weight: 3 parts of a hybrid nano-conductive material and 97 parts of a shape-memory polymer base material, the hybrid nano Conductive materials include metal nanowires and nanocarbon materials.

[0060] In the specific technical solution of the present invention, the metal nanowires are gold nanowires, the wire length of the gold nanowires is 25 μm, and the diameter is 65 nm, the nano-carbon material is reduced graphene oxide, and the gold nanowires The wire accounts for 17% by mass of the hybrid nano-conductive material, and the nano-carbon material accounts for 83% by mass of the hybrid nano-conductive material.

[0061] In the specific technical solution of the present invention, the thickness of the hybrid nano conductive material is 15 μm, the shape memory polymer base material is styrene-butadiene copolymer, and the mass range of the shape me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com