Cutter-suction dredger operation simulator

A technology of cutter suction dredger and simulation device, which is applied in the field of cutter suction dredger operation simulation device, can solve the problems of low operation output and low construction efficiency, and achieve increased output, extended service life, and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

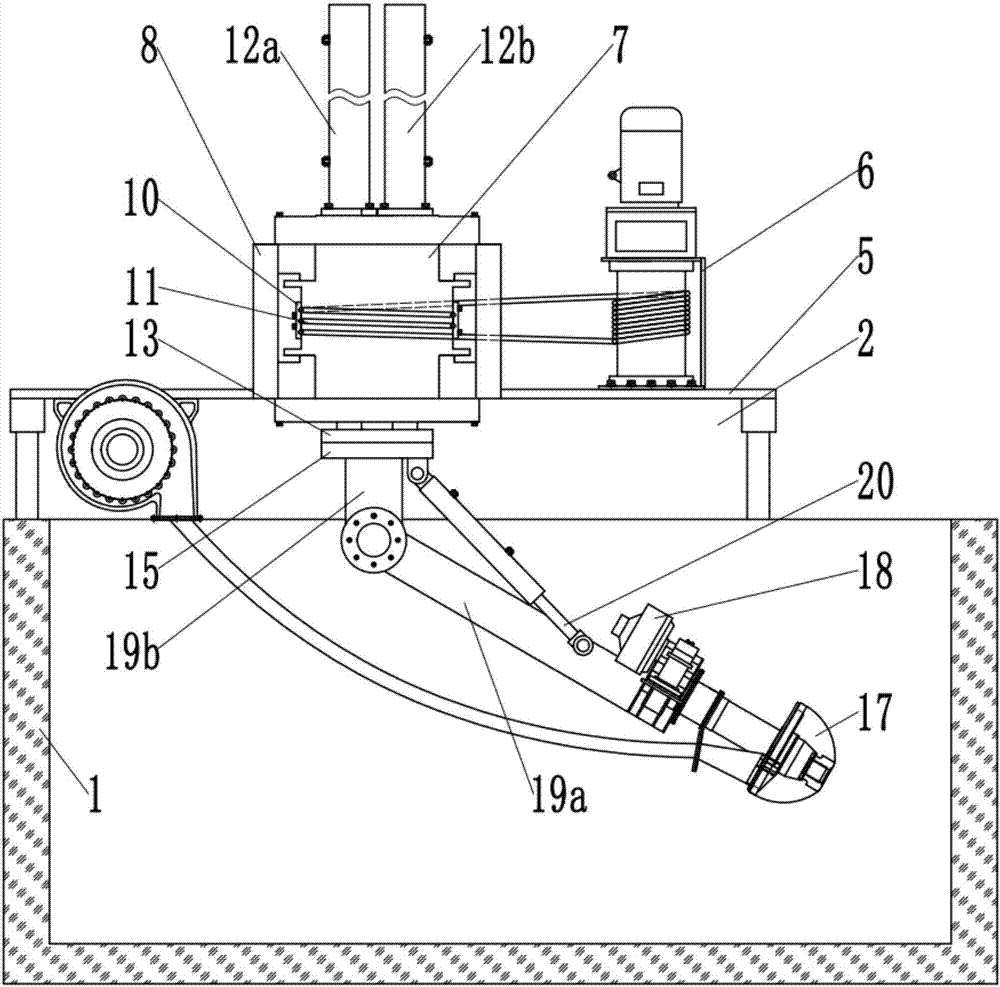

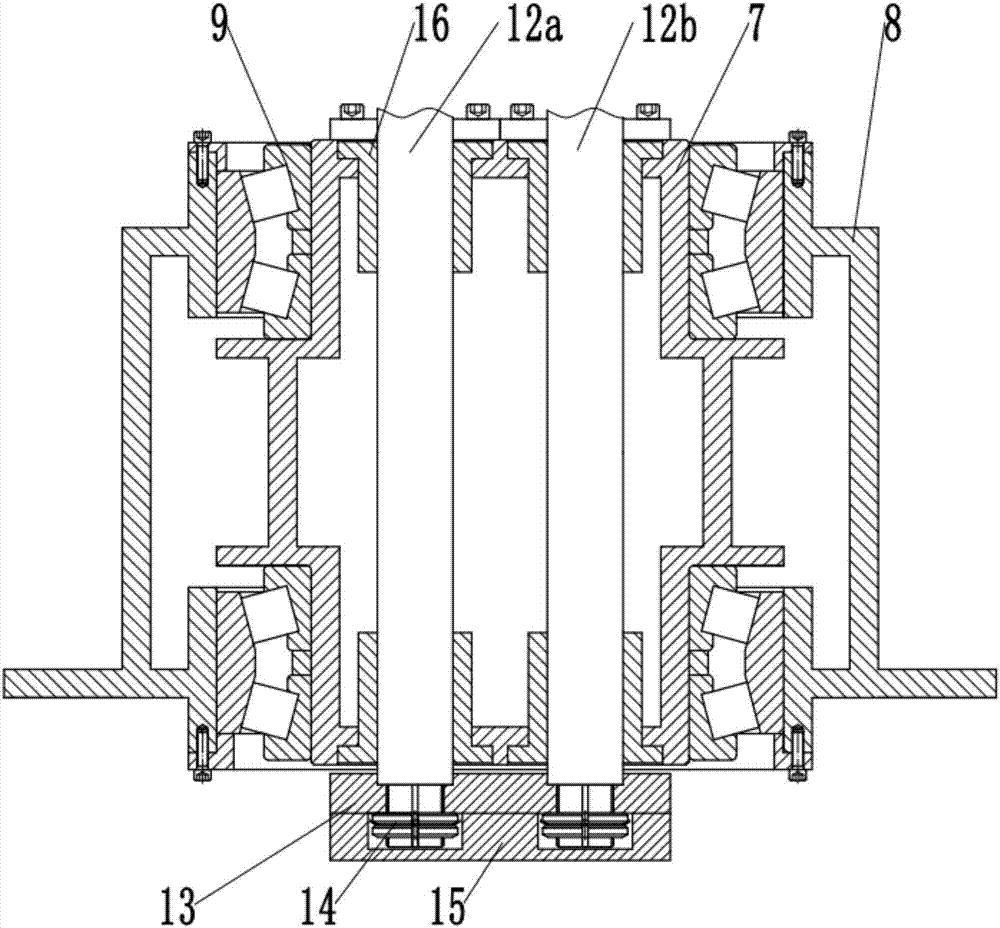

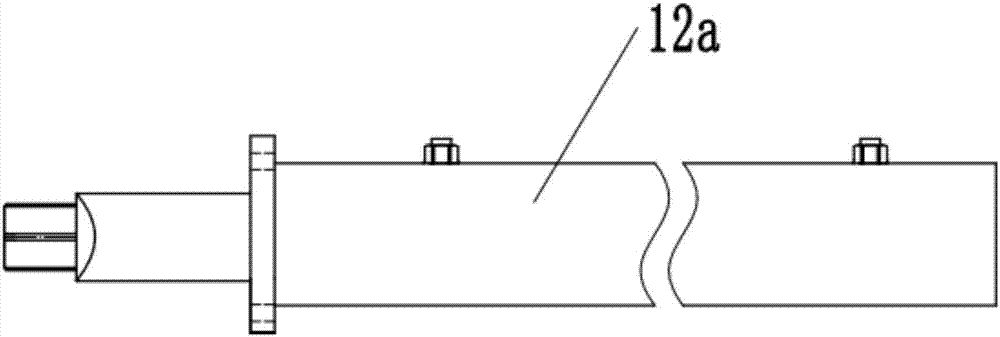

[0026] In the embodiment of the present invention, such as Figure 1-Figure 9 As shown, a cutter suction dredger operation simulation device is provided, including an experimental pool 1, a platform stepping mechanism, a reamer power output mechanism, a bridge rotation mechanism, and a bridge height adjustment mechanism. The platform stepping mechanism is set up in the experimental In Chishang, the bridge rotation mechanism includes a vertical planetary hoist 6, a cylindrical drum 7, a drum shell 8, double-row tapered roller bearings 9, and a steel rope 11. The bottom of the vertical planetary hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com