Quick coupling and working method thereof

A fast, male plug technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of unsatisfactory sealing performance and leakage, and achieve the effect of simple structure, ensuring fast circulation and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

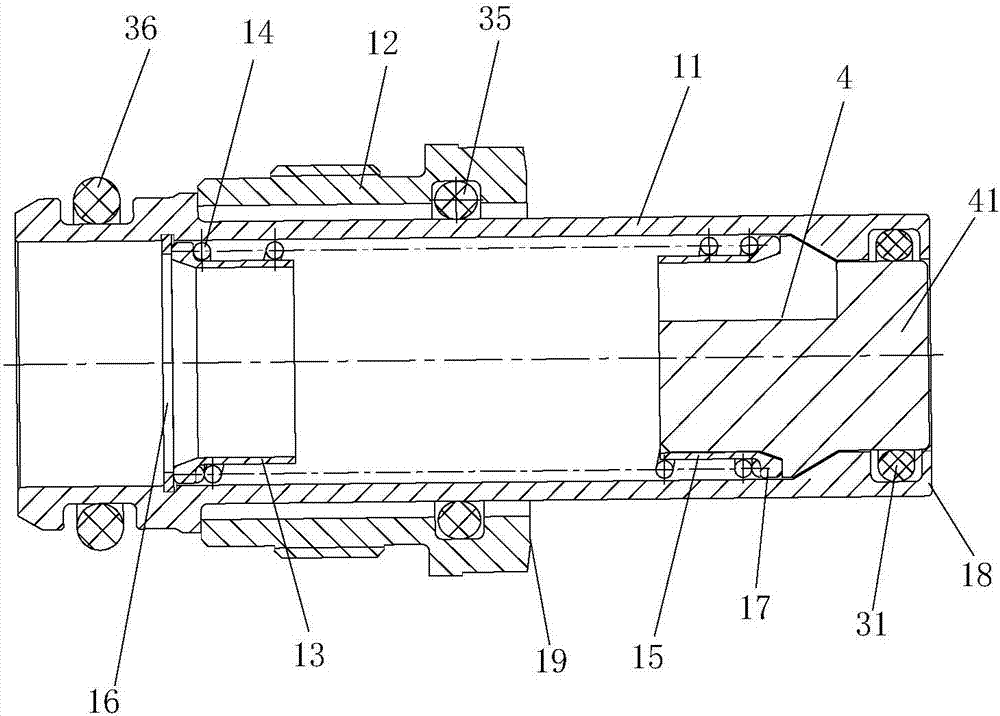

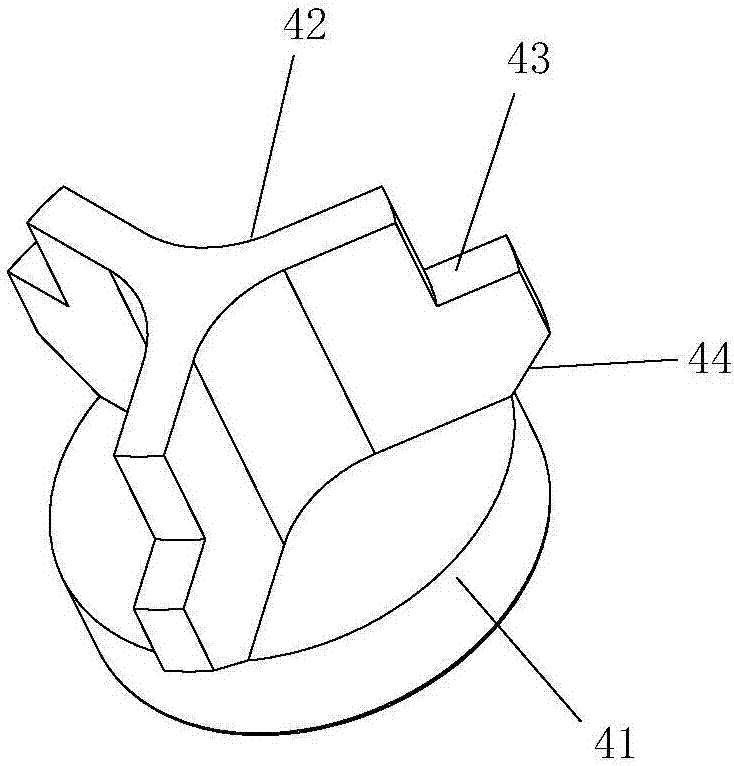

[0027] Embodiment 1 The quick connector of this embodiment includes a plug-fit male plug and a female plug (for the convenience of discussion, when referring to the front end, the components in the male plug refer to the end near the connection between the male plug and the female plug, and the opposite end is the tail end; when referring to the tail end, the parts in the female plug refer to the end near the connection between the male plug and the female plug, and the opposite end is the front end); figure 1 As shown, the male plug includes a male plug first sleeve 11 and a male plug second sleeve 12, and the male plug first sleeve 11 passes through the male plug second sleeve 12 so that the male plug second sleeve 12 A first annular step 19 is formed on the outer wall of the first sleeve 11 of the male plug; and a fifth annular groove is arranged on the inner wall of the second sleeve 12 of the male plug, and a fifth O-ring is arranged in the fifth annular groove 35, used f...

Embodiment 2

[0035] The working method of quick coupling as described in embodiment 1, comprises the steps:

[0036] A. When the male plug is in the initial state, the first spring 14 supports the first valve core 4 to reach the front end of the first sleeve 11 of the male plug, and the annular side wall of the first sealing disc 41 is in contact with the first sleeve 11 of the male plug. An annular sealing part 18 is sealed and fit through the first O-ring 31, so that the male plug is in a closed state; when the female plug is in the initial state, the second spring 24 supports the second valve core 5 to reach the front end of the first sleeve 21 of the female plug , the outer wall of the second spool 5 sealably fits with the second annular sealing portion 27 of the first sleeve 21 of the female plug through the second O-ring 32 and the third O-ring 33 , and the third of the second spool 5 The annular sealing portion 55 is sealingly matched with the annular side wall of the second sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com