A kind of water-based polyurethane imitation superfiber and manufacturing method thereof

A technology of water-based polyurethane and a manufacturing method, which is applied in the field of imitation microfiber, can solve the problems of difficult to control hand feeling, high recovery cost, low production efficiency and the like of water-based dry imitation microfiber, so as to solve the problems of difficult to control hand feeling, high production efficiency and three-dimensional strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

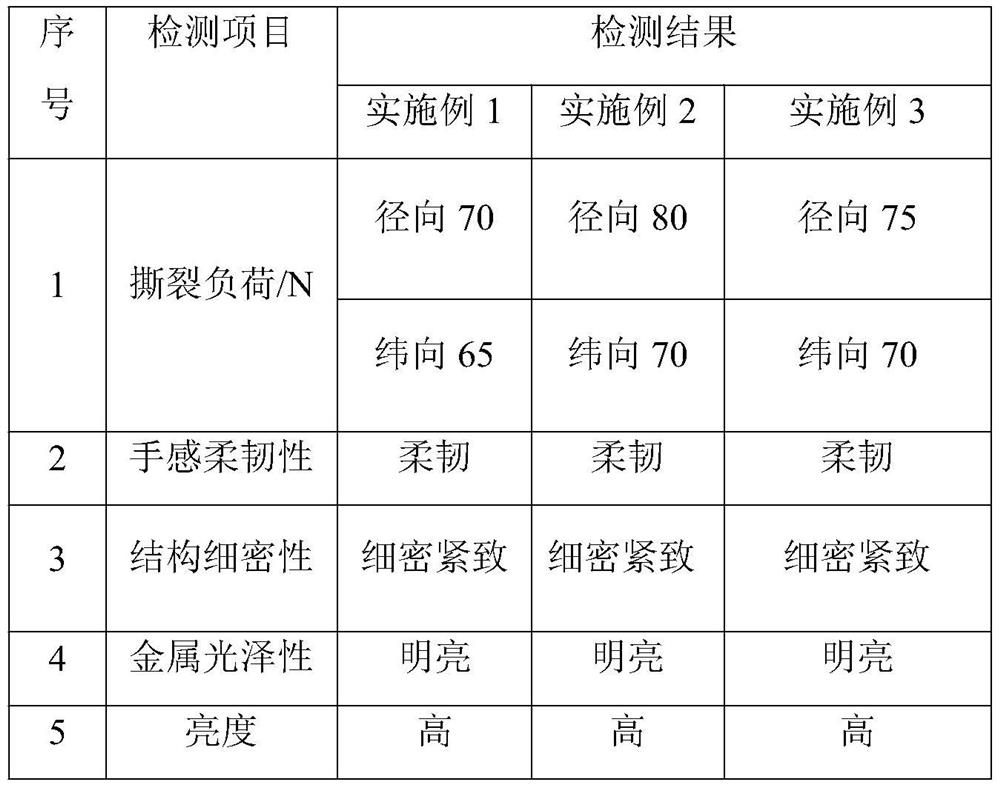

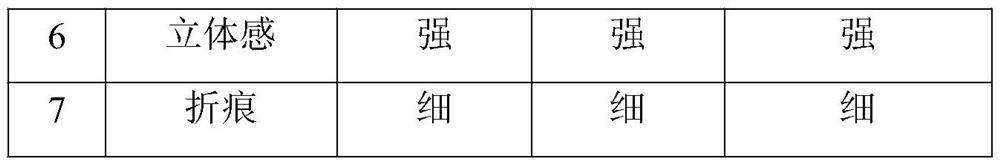

Examples

Embodiment 1

[0019] A kind of manufacture method of waterborne polyurethane imitation superfiber, comprises the following steps:

[0020] 1. Ingredients:

[0021] (1) Impregnated resin

[0022] 10 kg of water-based polyurethane KTL770 (Hefei Ketian Water-based Technology Co., Ltd., aliphatic resin) with a solid content of 30% was added to 10 kg of tap water, and water-based thickener 3220 (Shenzhen Haichuan Chemical Industry Co., Ltd.) was added, stirred evenly at high speed, and the viscosity was adjusted to 3500cps, pH 7.

[0023] (2) Preparation of coagulation solution

[0024] Mix and stir 10kg of phosphoric acid and 40kg of tap water to completely dissolve the phosphoric acid in the water.

[0025] 2. Preparation of water-based polyurethane imitation superfiber:

[0026] (1) Impregnation treatment: Place the double-sided fluff woven fabric in an impregnation tank filled with water-based polyurethane impregnation resin for impregnation treatment, and then squeeze out the excess imp...

Embodiment 2

[0031] A kind of manufacture method of waterborne polyurethane imitation superfiber, comprises the following steps:

[0032] 1. Ingredients:

[0033] (1) Impregnated resin

[0034] Add 12 kg of water-based polyurethane KTL775 (Hefei Ketian Water-based Technology Co., Ltd., aromatic resin) with a solid content of 30% to 8 kg of tap water, add the water-based thickener RHEOLATE208, stir evenly at high speed, adjust the viscosity to 2500cps, and the pH value 6.

[0035] (2) Preparation of coagulation solution

[0036] Mix and stir 20kg of calcium chloride and 80kg of tap water to completely dissolve the calcium chloride in the water.

[0037] 2. Preparation of water-based polyurethane imitation superfiber:

[0038] (1) Impregnation treatment: Place the double-sided fluff woven fabric in an impregnation tank filled with water-based polyurethane impregnation resin for impregnation treatment, and then squeeze out the excess impregnation resin through the pressing roller, so that...

Embodiment 3

[0043] A kind of manufacture method of waterborne polyurethane imitation superfiber, comprises the following steps:

[0044] 1. Ingredients:

[0045] (1) Impregnated resin

[0046] Add 30kg of water-based polyurethane KTL776 (Hefei Ketian Water-based Technology Co., Ltd., aromatic resin) with a solid content of 30% to 5kg of tap water, add water-based thickener 3220 (Shenzhen Haichuan Chemical Industry), stir evenly at high speed, and adjust the viscosity to 1500cps, pH 8.

[0047] (2) Preparation of coagulation solution

[0048] Mix and stir 3kg lactic acid, 6kg citric acid and 91kg tap water to completely dissolve phosphoric acid in the water.

[0049] 2. Preparation of water-based polyurethane imitation superfiber:

[0050](1) Impregnation treatment: Place the double-sided fluff woven fabric in an impregnation tank filled with water-based polyurethane impregnation resin for impregnation treatment, and then squeeze out the excess impregnation resin through the pressing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com