Car dumper hopper feeding control system and method

A control system and control method technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of heavy workload of the operator, and achieve the effects of improving operating efficiency, avoiding buckets, and adjusting accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

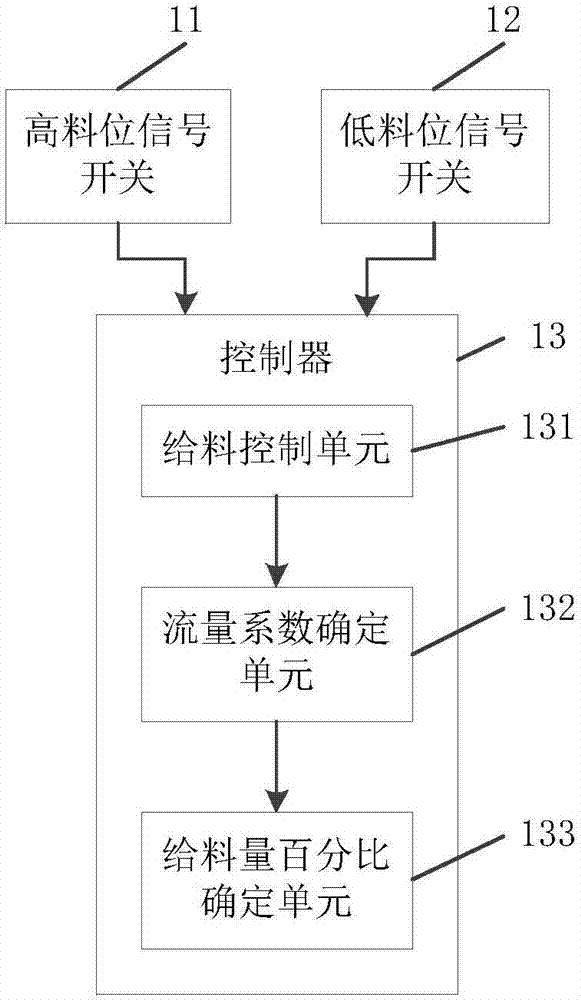

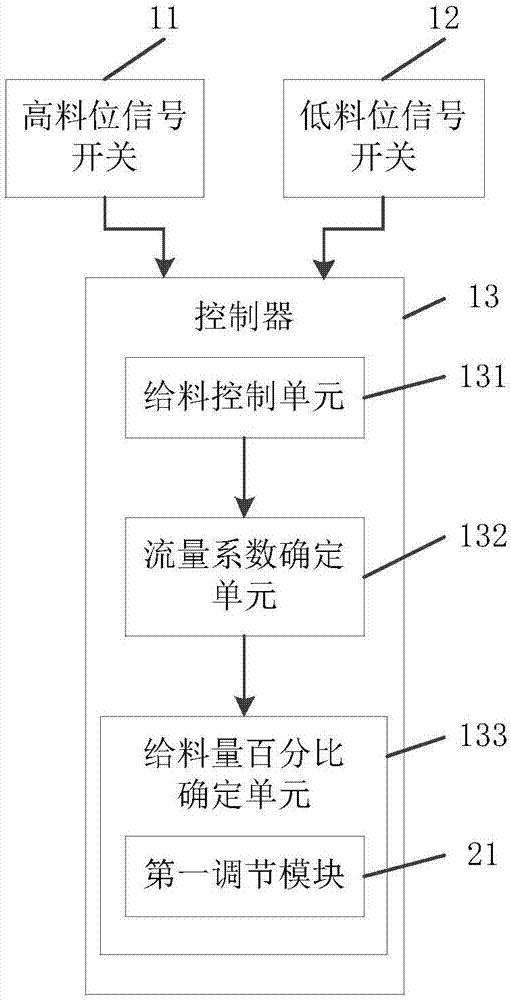

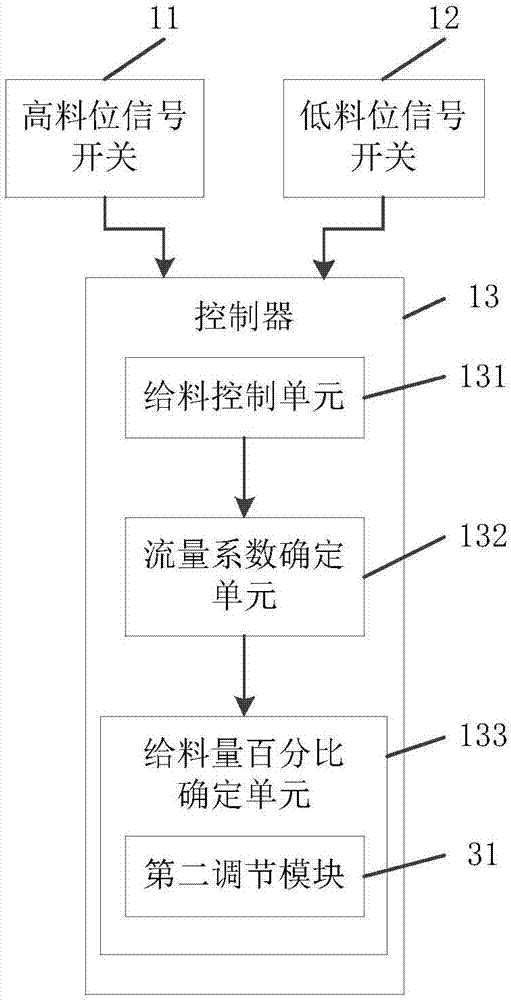

[0058] The embodiment of the present invention provides a hopper feeding control system for a wagon dumper, such as figure 1 As shown, the system includes a high material level signal switch 11, a low material level signal switch 12, and a controller 13.

[0059] Wherein, the high material level signal switch 11 is vertically arranged on the upper grille of each hopper;

[0060] The low material level signal switch 12 is horizontally arranged at a preset distance under the bottom cross beam of each funnel;

[0061] The controller 13 includes:

[0062] The feeding control unit 131 is configured to sequentially turn on a plurality of hopper activation feeders at predetermined inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com