Four-stage iron core cast-aluminum rotor with skewed slot structure, stator and motor

A technology of cast aluminum rotor and iron core, which is applied in the field of four-section iron core cast aluminum rotor, motor, and stator, which can solve the problems of motor failure to start, achieve the effects of small additional loss, reduce synchronous additional torque, and weaken tooth harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

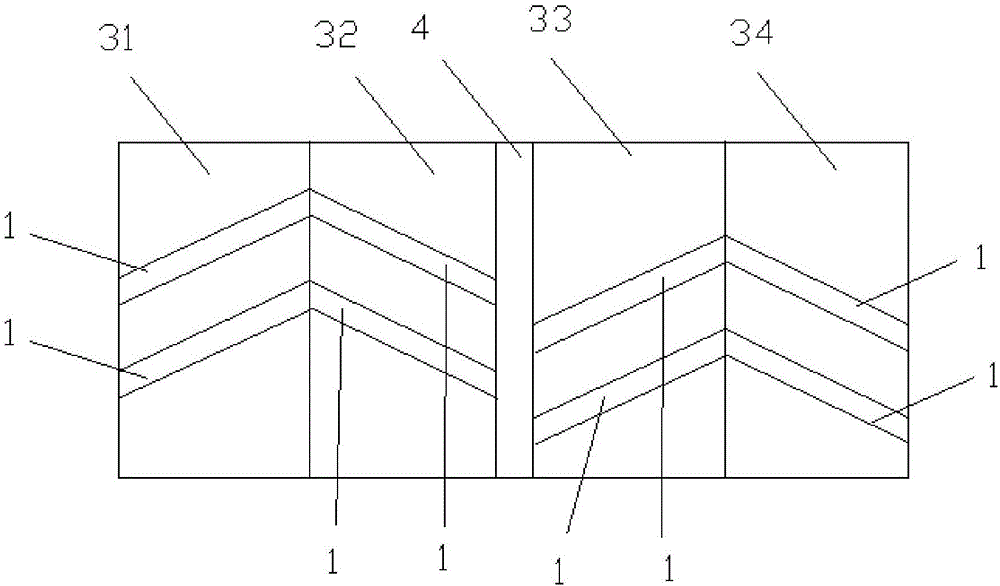

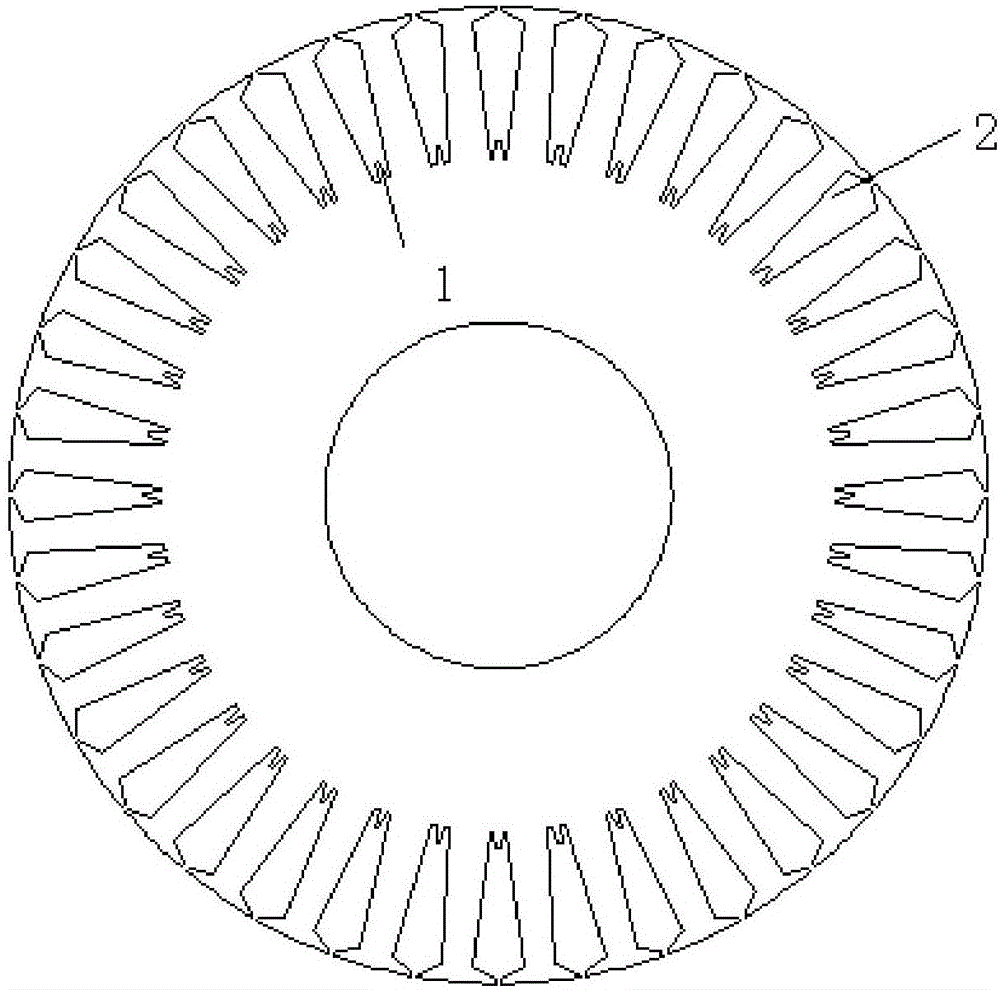

[0024] Such as figure 1 , 3 As shown, this embodiment discloses a four-section iron core cast aluminum rotor with a chute structure, and the number of slots of the rotor is the same as that of the stator. The rotor includes a rotor core, a rotating shaft and guide bars 2 . A rotor iron core is sleeved on the rotating shaft. The slot body 1 of the iron core is skewed, and the guide bar 2 is cast in the slot body 1 of the iron core. The iron core includes two sections of the second iron core 32 and the third iron core 33 located between them. It is divided into a first iron core 31 and a fourth iron core 34 located at both ends. The two slot bodies 1 opposite to each other in the first iron core 31 and the second iron core 32 , and the third iron core 33 and the fourth iron core 34 are oppositely twisted to form a herringbone shape. An intermediate ring 4 is disposed between the second iron core 32 and the third iron core 33 . The two slot bodies 1 opposite to each other i...

Embodiment 2

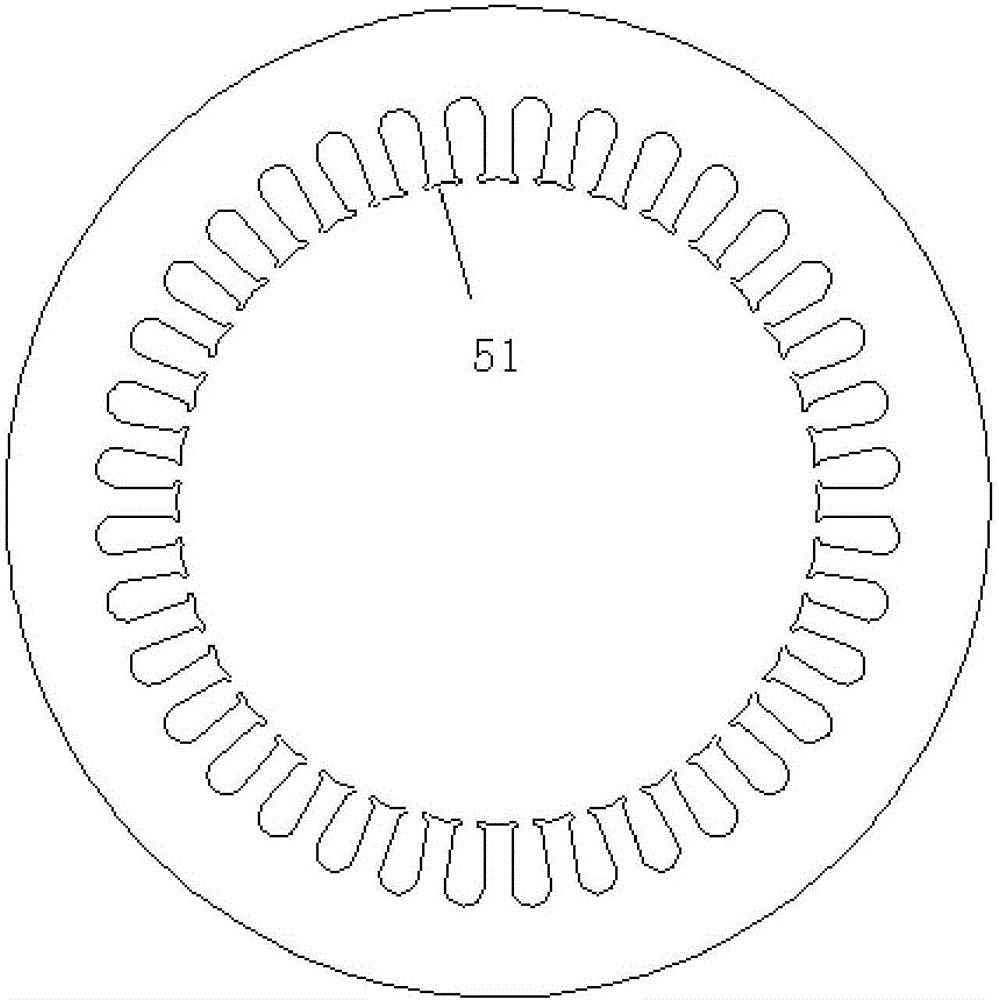

[0027] Such as figure 2 As shown, a stator matched with the rotor of the above embodiment, the rotor is installed in the stator. The number of slots in the stator and the rotor is equal, and the teeth of the stator are provided with arc-shaped grooves 51 . The stator teeth are provided with arc-shaped grooves 51 to make the air-gap flux density more sinusoidal and reduce harmonic loss.

Embodiment 3

[0029] Such as Figure 1-3 As shown, a motor includes a casing, a stator, a cast aluminum rotor, and a rotating shaft. The stator is set in the inner cavity of the casing, and the cast aluminum rotor is built in the stator and fixedly installed on the rotating shaft. The rotating shaft runs through the shell and is rotatably connected with the shell. The stator teeth are provided with arc-shaped grooves 51 to make the air-gap flux density more sinusoidal and reduce harmonic loss.

[0030] The rotor has the same number of slots as the stator. The teeth of the stator are provided with arc-shaped grooves 51 . The rotor includes a rotor core, a rotating shaft and guide bars 2 . A rotor iron core is sleeved on the rotating shaft. The slot body 1 of the iron core is skewed, and the guide bar 2 is cast in the slot body 1 of the iron core. The iron core includes two sections of the second iron core 32 and the third iron core 33 located between them. It is divided into a first i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com