Method for improving CAE analysis precision in high-pressure casting mold-filling process

A high-pressure casting and precision analysis technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not being able to understand the real-time status, achieve the effects of shortening the development cycle, improving product yield, and solving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

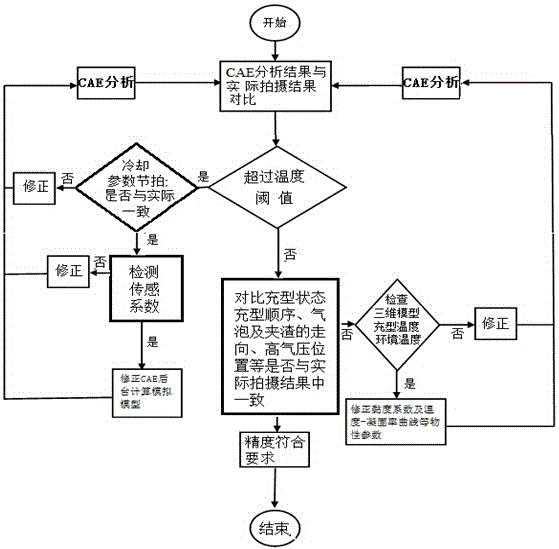

[0018] like figure 1 As shown in the figure, a method for improving the CAE analysis accuracy of the high-pressure casting mold filling process, the specific steps are:

[0019] Step 1. Use the CAE software to simulate the high-pressure filling process of the casting: first, import the 3D model and material properties of the casting into the CAE software; then set the CAE analysis parameters according to the actual production process, and conduct the CAE simulation of the high-pressure casting process. Parts and materials for material property assignments include: castings, molds, sand cores, sprue cups, risers, pressure chambers, punches, risers, runners, sprues, overflow troughs, exhaust pipes, cooling pipes , Properties of thermal insulation materials.

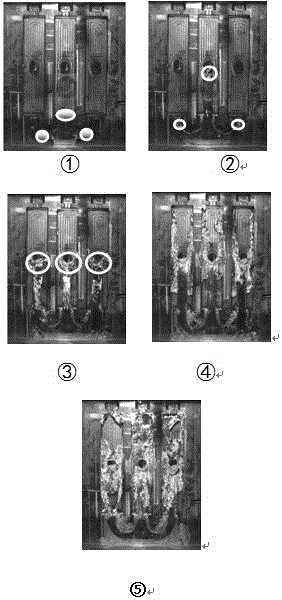

[0020] Step 2, using the high-pressure casting visualization device to photograph the high-pressure filling process of the casting;

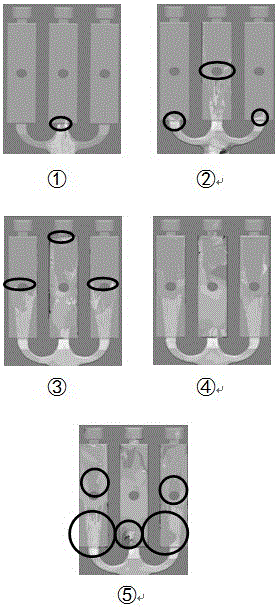

[0021] Step 3: Compare the CAE analysis results with the actual shooting results, fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com