Motor testing system

A motor testing and motor driver technology, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of difficult to meet testing requirements, low degree of automation, low testing efficiency, etc., and achieve high-efficiency automatic testing and testing. full effect of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

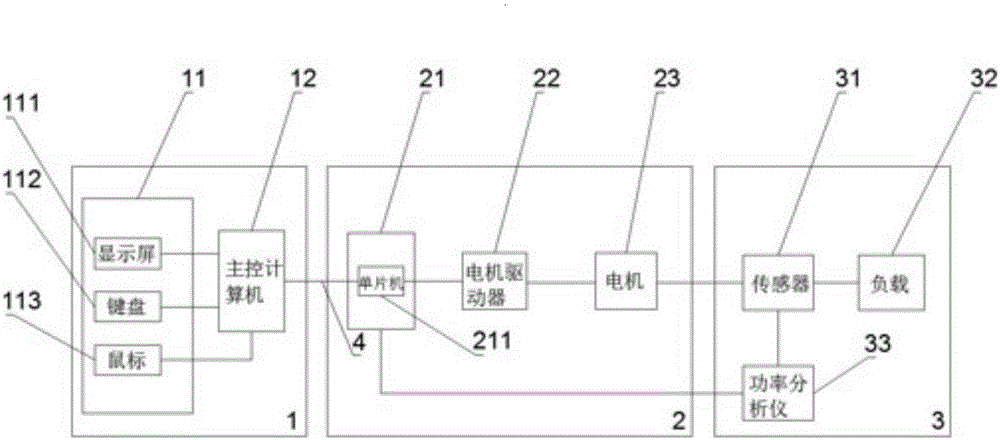

[0021] see figure 1 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention, a motor testing system, mainly including: a main control part 1, a driving part 2 and a testing part 3, and the driving part 2 is provided with a motor driver 22 and a motor 23. The drive part 2 is provided with a controller 21 for outputting instructions. The drive part 2 is connected to the main control part 1 through GPIB4. The main control part 1 mainly includes a main control computer 12 and peripheral equipment 11, and the peripheral equipment 11 includes a display screen 111, keyboard 112 and mouse 113, described testing part 3 comprises sensor 31, load 32 and power analyzer 33, sensor 31 is installed between moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com