Friction discs, in particular for motor vehicles

A technology for motor vehicles and friction discs, which is applied to friction linings, friction clutches, mechanical drive clutches, etc., and can solve the problems of repetitive and boring assembly operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

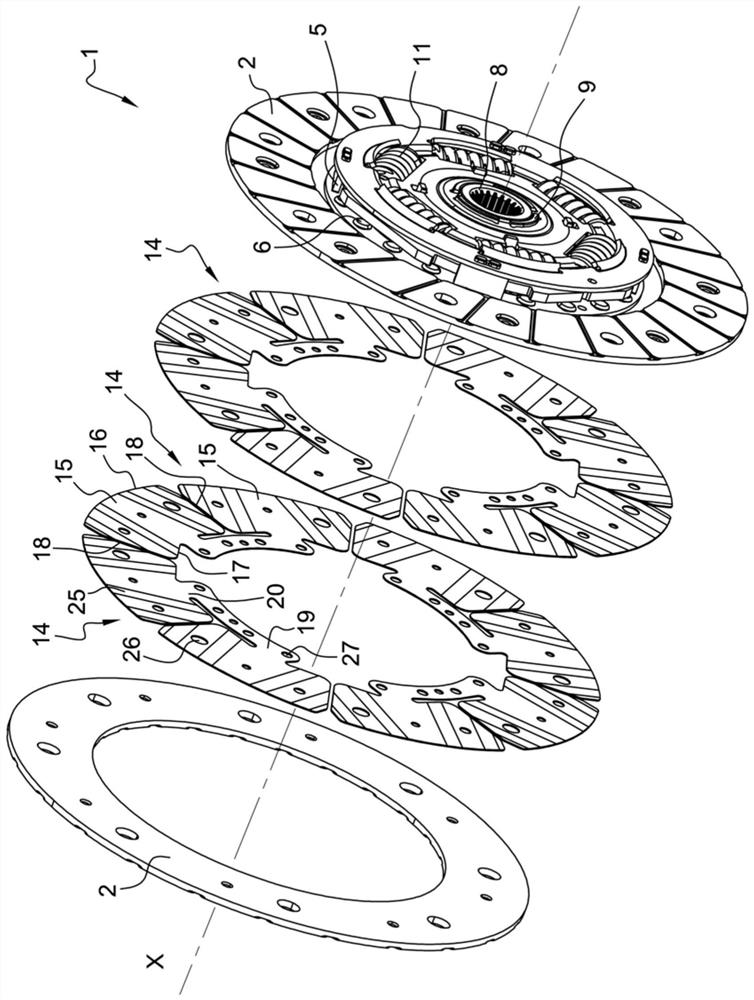

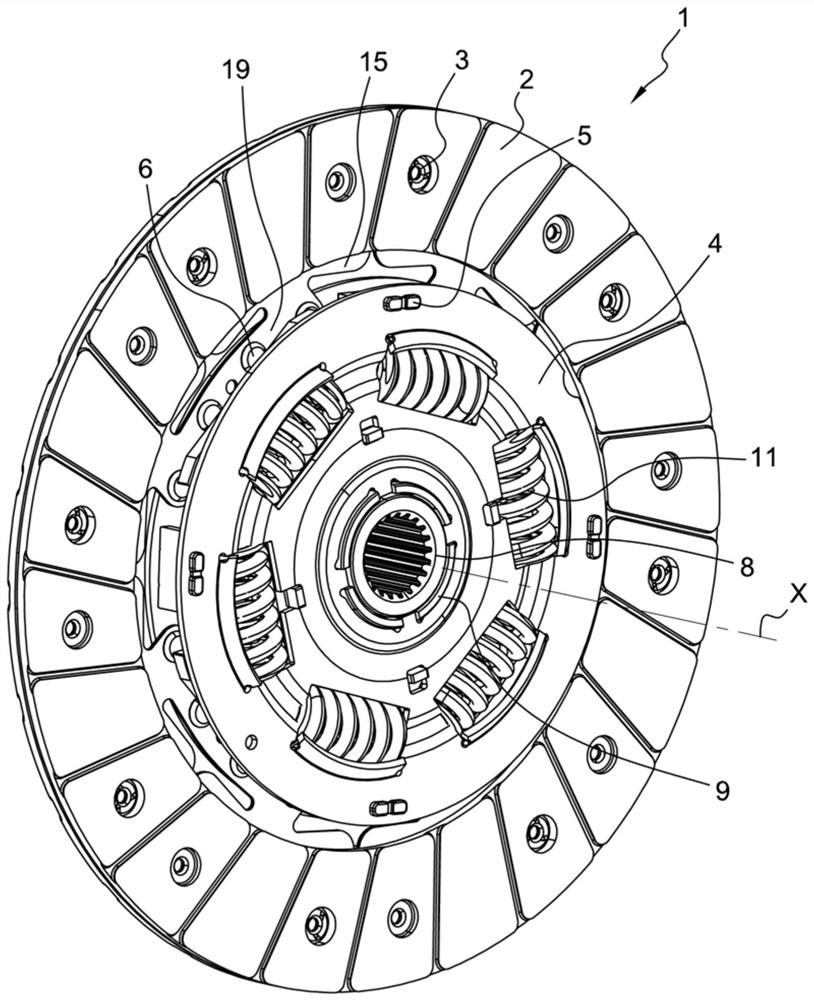

[0035] Figures 1 to 4 A friction disk 1 for a motor vehicle according to a first embodiment of the invention is shown. The friction disk 1 has an axis X and annular friction linings 2 which are located axially on both sides of the support via rivets 3 . The terms "axial" and "radial" are defined with reference to the axis X. The friction disk 1 additionally has two annular guide washers 4 which are fixed to each other via spacers 5 which extend axially and are riveted to said guide washers 4 at their ends. The support is fixed to one of said guide washers 4 via rivets 6 .

[0036] The friction disk 1 additionally has a radial annular web 7 which is positioned axially between the guide washers 4 . The radially inner circumference of the link plate 7 is rotationally coupled to a splined hub 8 which is intended to be rotationally coupled to the input shaft of the gearbox.

[0037] The guide washer 4 is mounted and guided in rotation about the hub 8 via a slide bearing 9 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com