Rapid spindle replacing device on textile machine

A textile machinery and fast technology, applied in textiles and papermaking, etc., can solve the problems of inconvenient clamping and small use range, and achieve the effects of simple structure, improved production efficiency, and fixed time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

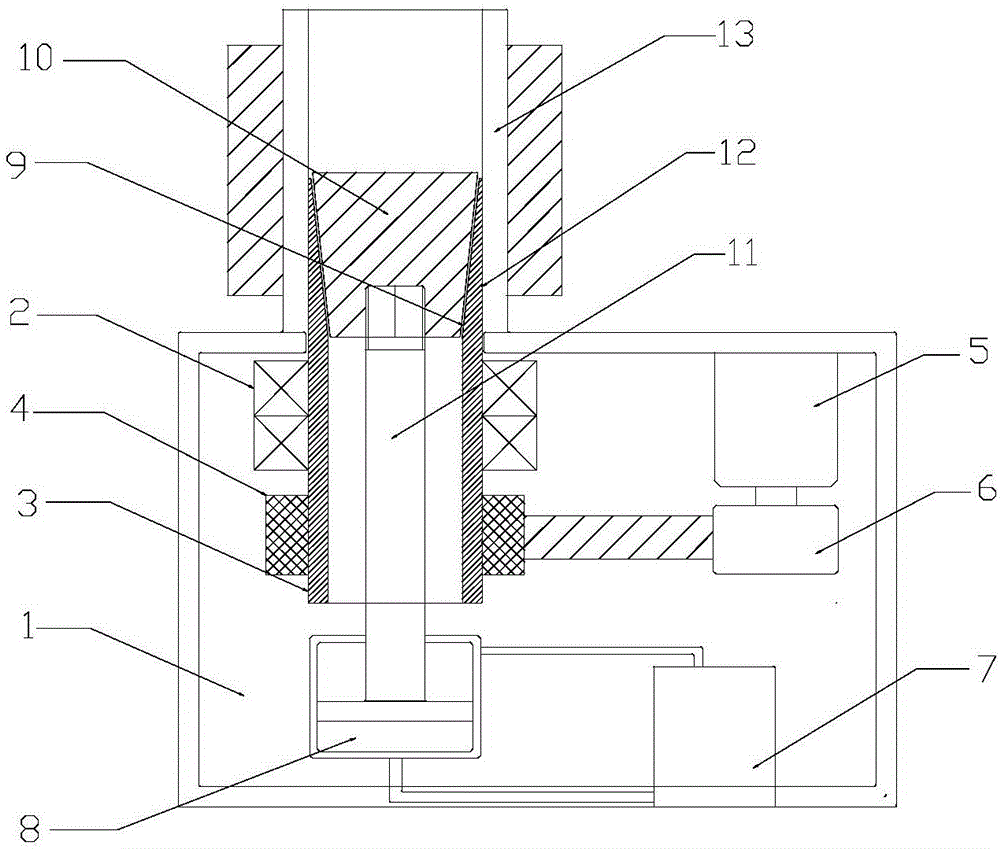

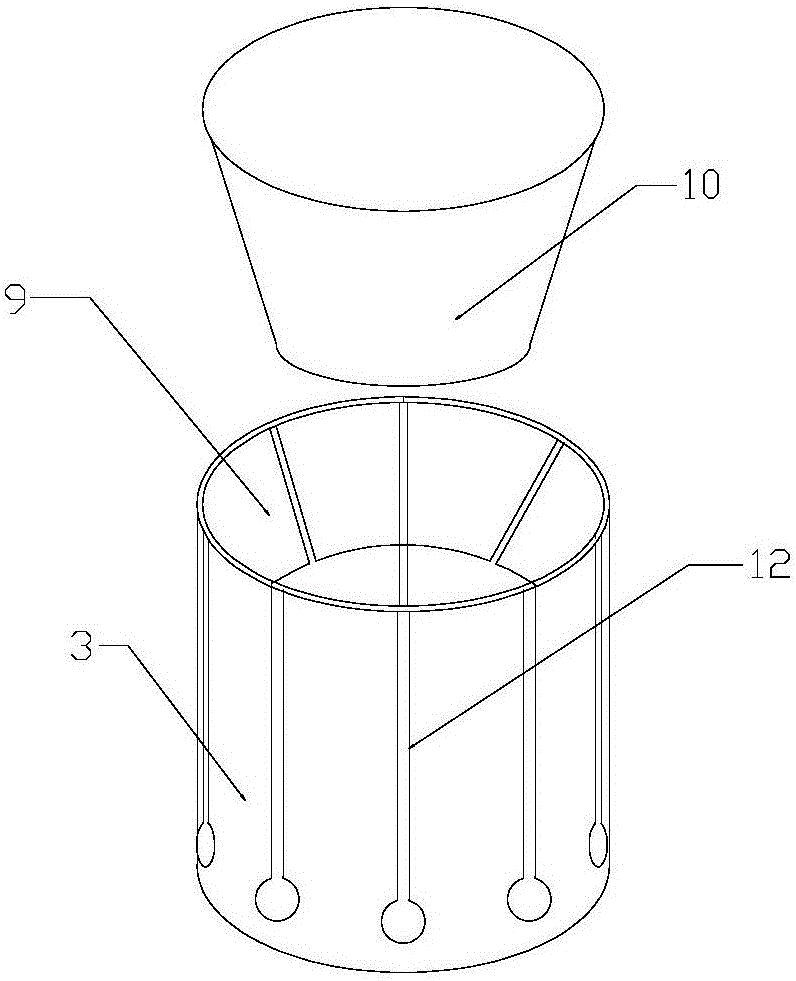

[0017] Such as Figure 1-2 As shown, the present invention provides a quick spindle changing device on a textile machine, comprising a device main body 1, a rotating spindle 3, a motor 5, an electromagnetic reversing valve 7 and a rotating cylinder 8, the device main body 1 is a hollow box, and the device main body 1. One side of the inner wall of the top end is fixed with a rotating main shaft 3 through a bearing 2. The rotating main shaft 3 is a hollow circular tube. The bottom end of the rotating main shaft 3 is sleeved with a rotating main shaft pulley 4. The side is fixedly provided with a motor 5, the rotating shaft of the motor 5 is sleeved with a motor pulley 6, the motor pulley 6 is connected to the rotating main shaft pulley 4 through belt friction, and one side of the bottom end of the device main body 1 is fixedly provided with an electromagnetic reversing valve 7, and the device main body 1 The other side of the bottom end is fixed with a rotary cylinder 8 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com