A kind of core-shell water-locking material and its preparation method and application

A water-locking, core-shell technology, which is applied in the field of core-shell water-locking materials and their preparation, can solve the problems of facilitation of water, recovery of solvents in the preparation process, complex dispersants, and inability to lock water, so as to achieve reasonable size and high efficiency. One-way water-locking performance, the effect of improving the performance of photochemical water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

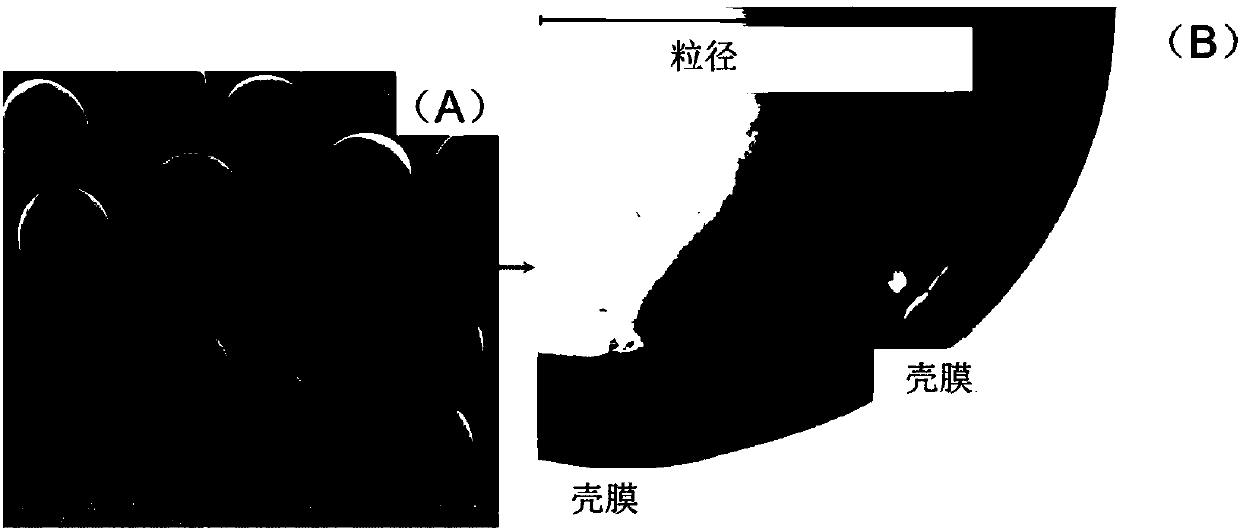

Image

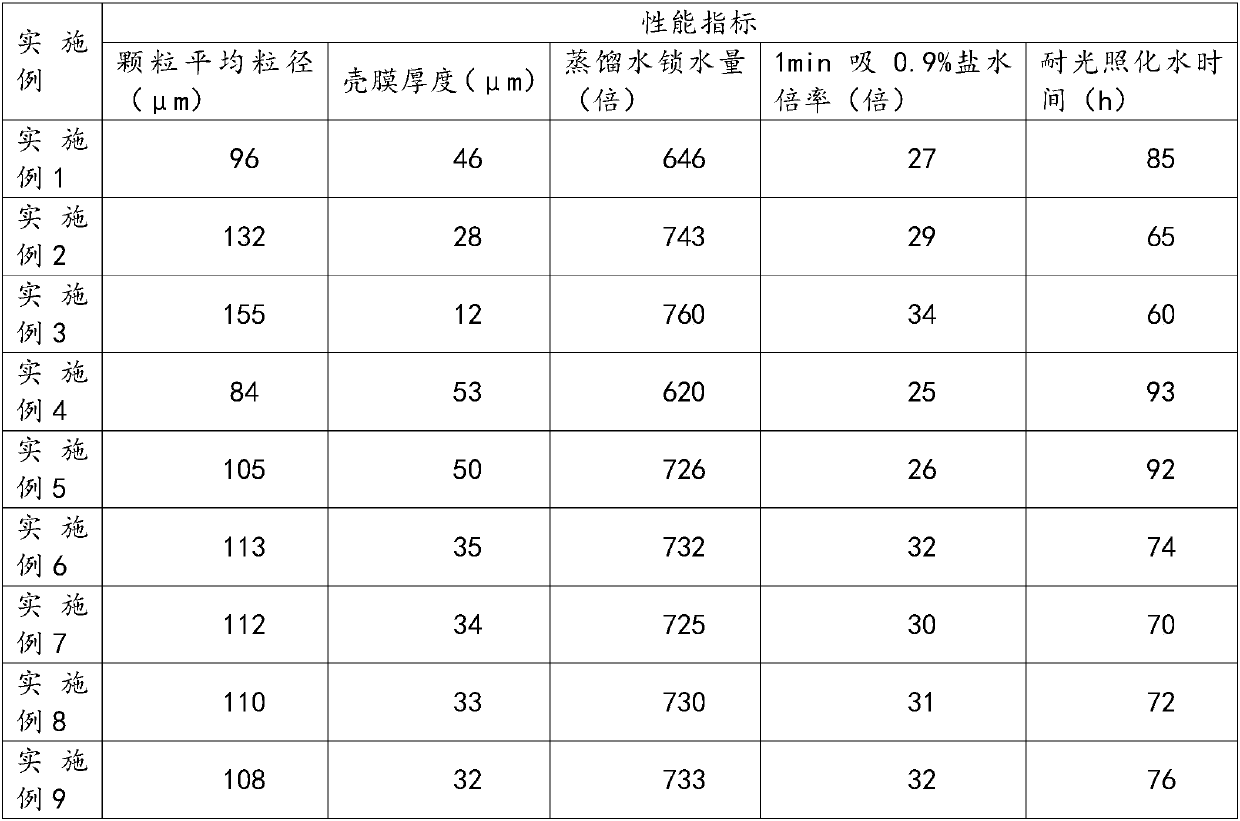

Examples

Embodiment 1

[0028] Preparation method of core-shell water-locking material:

[0029] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of hydroxyethyl acrylate were added.

[0030] ② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumizole hydrochloride: 0.2g, potassium persulfate: 0.05g, carbonic acid Sodium hydrogen: 1.6g, urea: 4.8g, ethanol: 3.2g; mix well and set aside.

[0031] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect...

Embodiment 2

[0033] Preparation method of core-shell water-locking material:

[0034] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of acrylamide was added.

[0035] ② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumisole hydrochloride: 0.2g, ammonium persulfate: 0.05g, carbonic acid Sodium hydrogen: 1.6g, urea: 4.8g, ethanol: 3.2g; mix well and set aside.

[0036] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect the product,...

Embodiment 3

[0038] Preparation method of core-shell water-locking material:

[0039] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of acrylamide was added.

[0040]② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumizole hydrochloride: 0.2g, potassium persulfate: 0.05g, carbonic acid Potassium hydrogen: 1.6g, urea: 4.8g, acetone: 3.2g; mix well and set aside.

[0041] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com