Farmland planting machine

A planting machine and farmland technology, applied in the field of agricultural machinery, can solve problems such as low operating efficiency, lack of seedlings and ridges, labor shortage, etc., and achieve the effects of reducing manual use, uniform seedlings, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

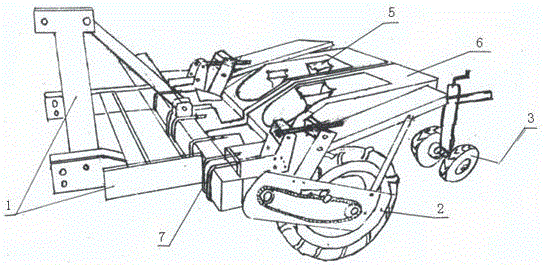

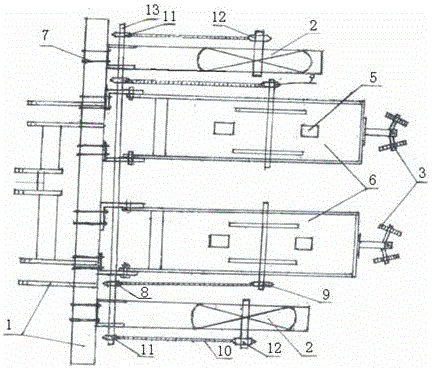

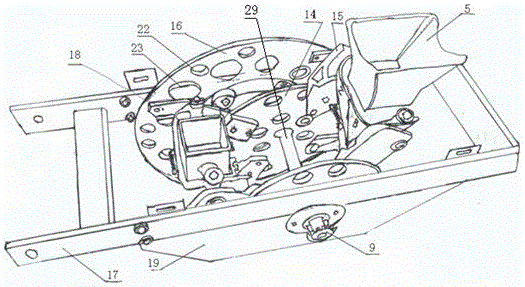

[0026] Example 1: Reference Figure 1-5 . The farmland planting machine of the present embodiment includes a suspension frame 1, a tire assembly 2, a closing compacting wheel set 3, a clamping groove 4, a duckbill inserter assembly 5, a transplanting box body 6, a movable clip 7, and a Bridge sprocket Ⅱ8, power input sprocket 9, chain 10, bridge sprocket Ⅰ11, power output sprocket 12, power distribution shaft 13, inserter turntable 14, track control board 15, directional disc 16, fixed bracket 17, connection Plate 18, supporting plate 19, tension spring 20, insert body 21, weight-reducing hole 23, mounting hole 22, funnel holder 24, fixed rotating shaft 25, draw-in groove 26, rolling bearing 27, rotating shaft 28, power input shaft 29, rice seedling Funnel 30.

[0027] The farmland planting machine of the present embodiment is made up of suspension frame 1, tire assembly 2 and transplanting machine box 6, specifically is that suspension frame 1 is connected on the tractor hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com