Non-shaft-core dual-ball hinge

A double ball and hinge technology, which is applied to hinge plates, door/window accessories, buildings, etc., can solve the problems of shaft core and hinge tube inner wall wear, large resistance, hinge tube wear, etc., to prolong the service life , Small rolling friction and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

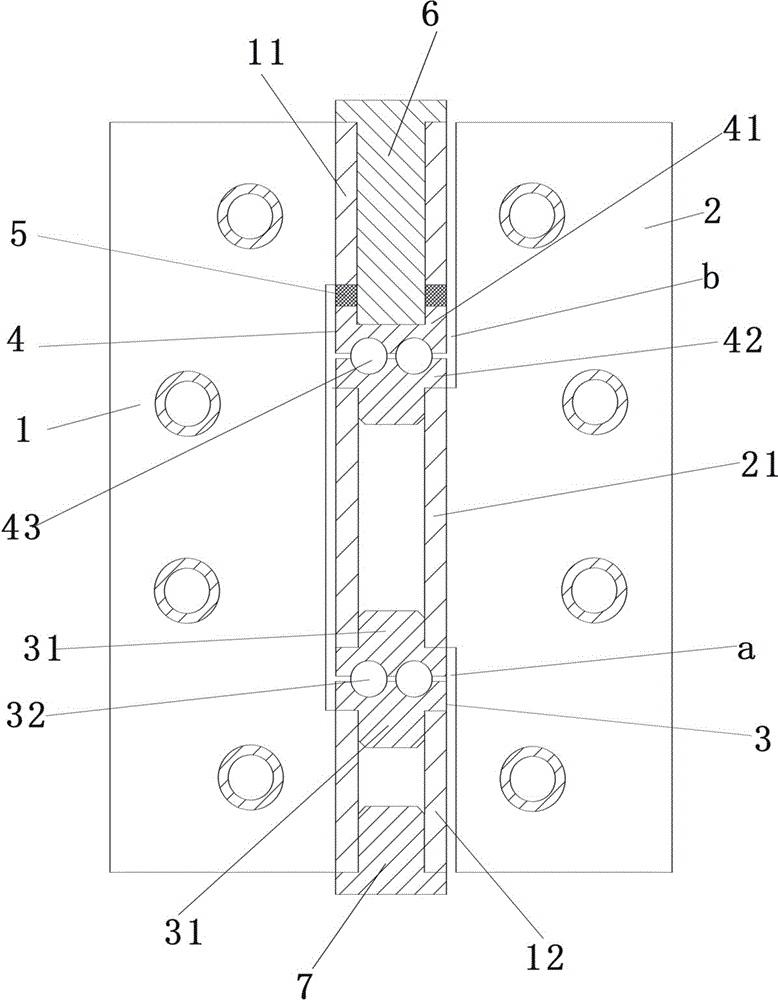

[0025] refer to figure 1 , figure 2 , image 3 and Figure 4 , the non-axis core double ball hinge, including the connecting leaf 1 and the connecting leaf 2, the upper hinge tube 11 and the lower hinge tube 12 are formed on the side of the connecting leaf 1, and the middle hinge tube 21 is formed on the side of the connecting leaf 2 , the middle hinge tube 21 is located between the upper hinge tube 11 and the lower hinge tube 12, and there is a gap between the middle hinge tube 21, the upper hinge tube 11, and the lower hinge tube 12, which is the upper gap b and lower gap a;

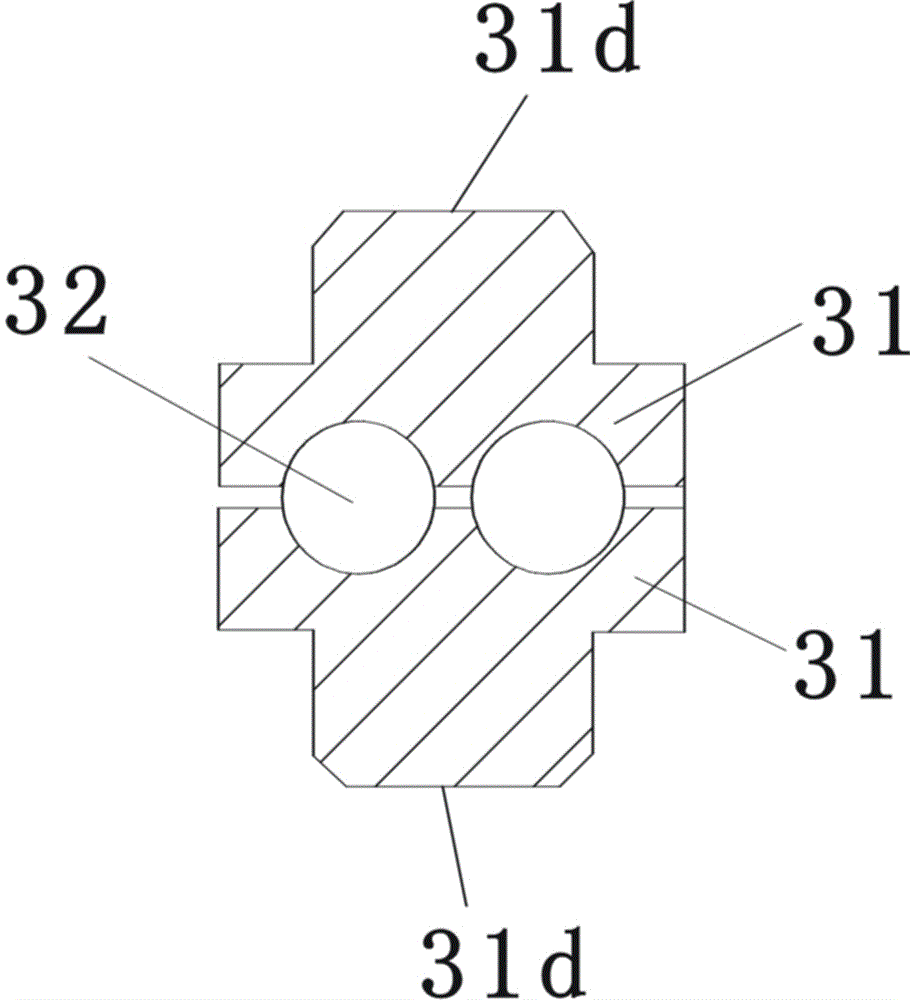

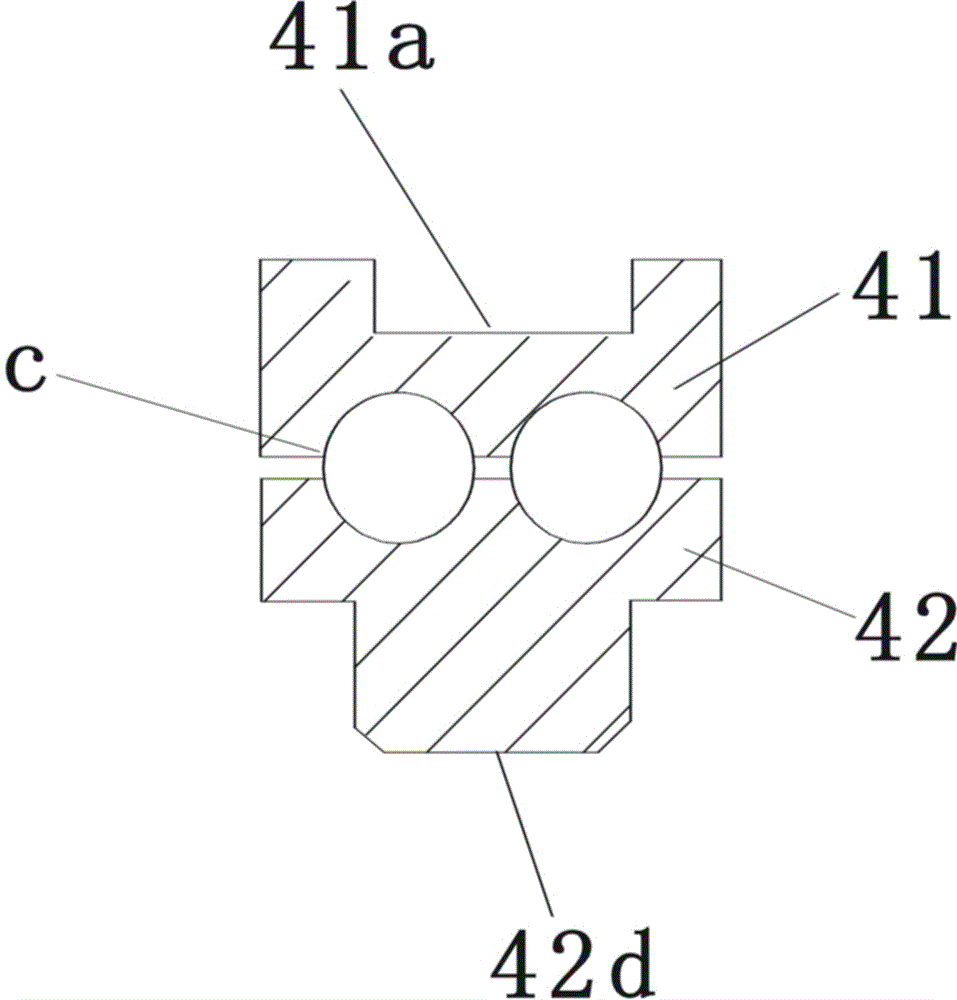

[0026] A lower ball bearing 3 is installed at the lower gap a, the lower ball bearing 3 includes a pair of bead discs 31 and a plurality of balls 32, the bead disc 31 has an annular groove c with a semicircular cross section, and the two bead discs 31 face each other A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com