storage yarn feeder

A yarn feeder and yarn storage spool technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of high fabric defects, low loom efficiency, easy overlapping of yarn loops, etc., and achieve a wide range of yarn tension. , The structure design is reasonable, and the effect of improving the efficiency of the loom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

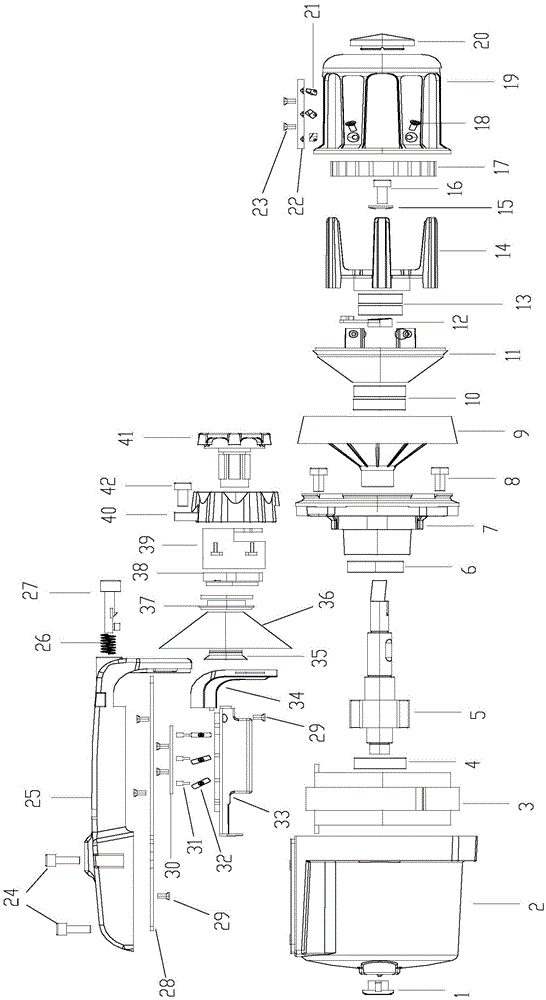

[0018] As shown in the figure, for the storage type yarn feeder of the present invention, the rear end of the base motor housing 2 is provided with a yarn guide porcelain eye seat 1; the inside of the base motor housing 2 is fixedly installed with a motor iron core 3 In the motor iron core 3, the first motor bearing 4 is fixed to form a rotational connection with the motor rotor and one end of the rotating shaft 5, and the motor rotor and the rotating shaft 5 form a rotational connection with the second motor bearing 6, and the second motor bearing 6 is fixedly installed in front of the motor The rear end of the support cover plate 7, the front support cover plate 7 of the motor is fixed on the front end of the motor housing 2 of the machine base through the motor fastening screw 8; The disk 9 forms a transmission connection with the motor rotor and the rotating shaft 5; the front end of the yarn winding conveying disk 9 is inserted with a magnetic positioning support frame 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com