Heat dissipation unit

A heat dissipation unit and heat dissipation module technology, which is applied in the direction of electrical components, cooling/ventilation/heating transformation, electrical equipment construction parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the embodiments of the accompanying drawings.

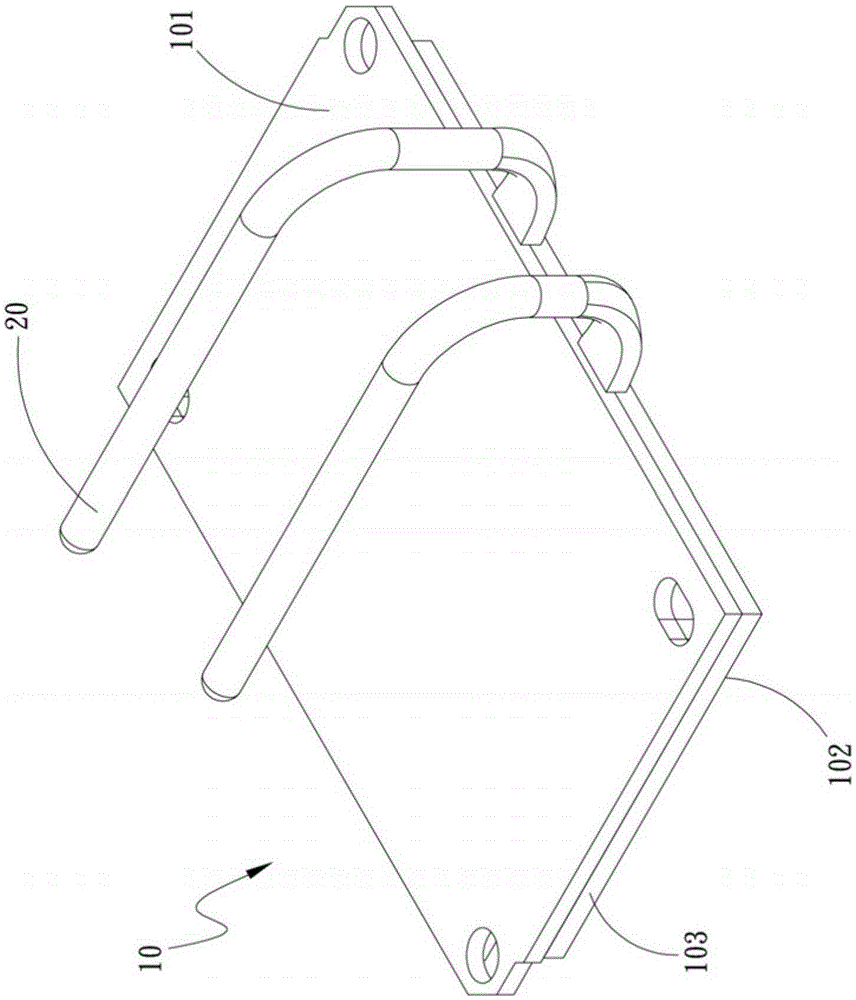

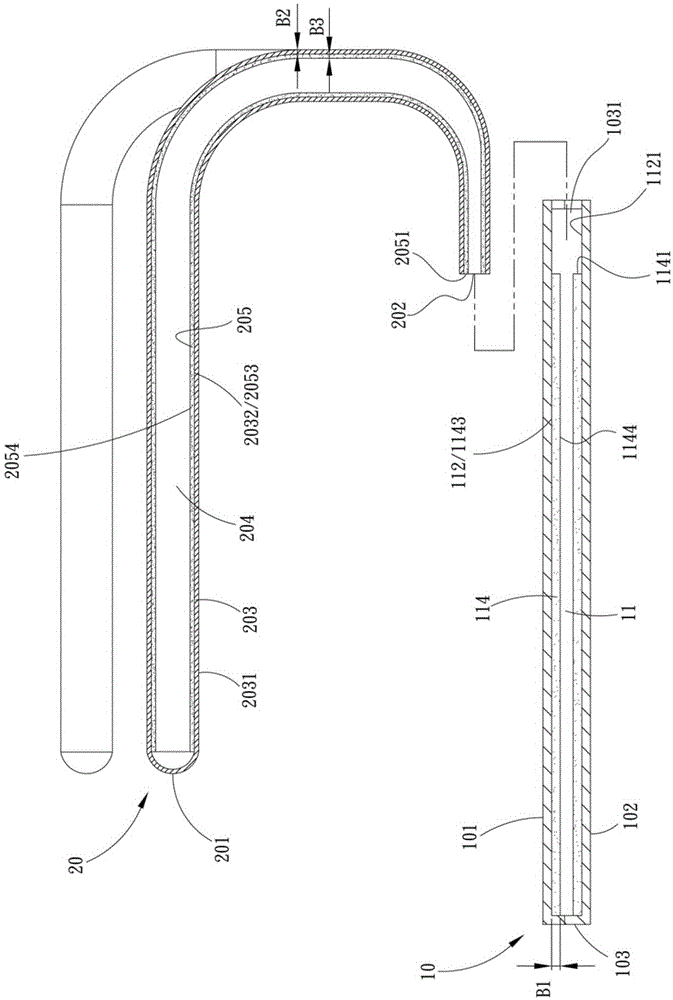

[0062] see figure 1 It is a three-dimensional exploded schematic diagram of the present invention; figure 2 It is a three-dimensional combination schematic diagram of the present invention; image 3 It is a cross-sectional exploded schematic diagram of the present invention; Figure 4 It is a cross-sectional schematic diagram of the present invention; Figure 5 for Figure 4 The local enlarged schematic diagram. As shown in the figure, the present invention includes a casing 10 and at least one heat pipe 20 . The casing 10 is a flat heat conduction unit, such as a vapor chamber or a flat heat pipe, and has a top side 101, a bottom side 102 and a side edge 103 arranged between the top side 101 and the bottom side 102. . The side 103 defines at least one opening 1031 , and the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com