Converter Feedback Control Circuit

A technology of feedback control and converter, which is applied in the field of interconnection system control, and can solve problems such as the inability to equalize the input voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

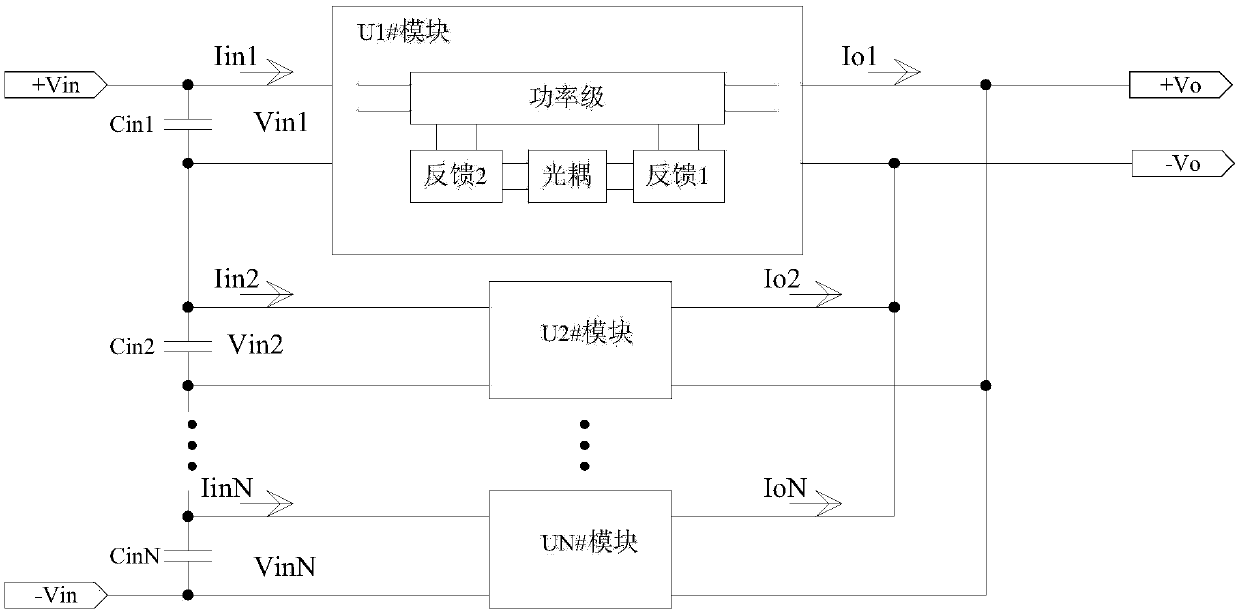

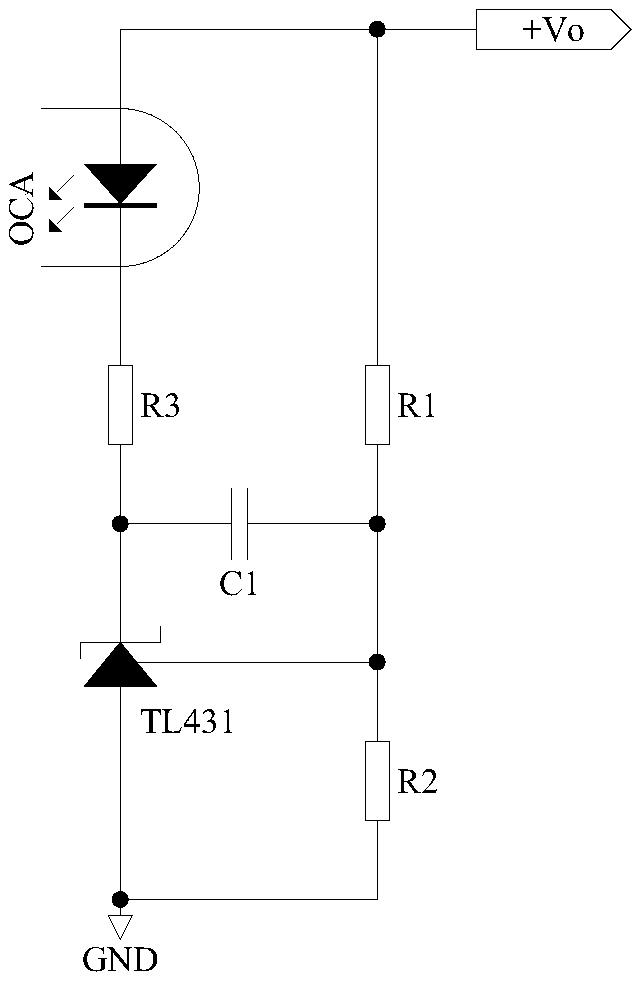

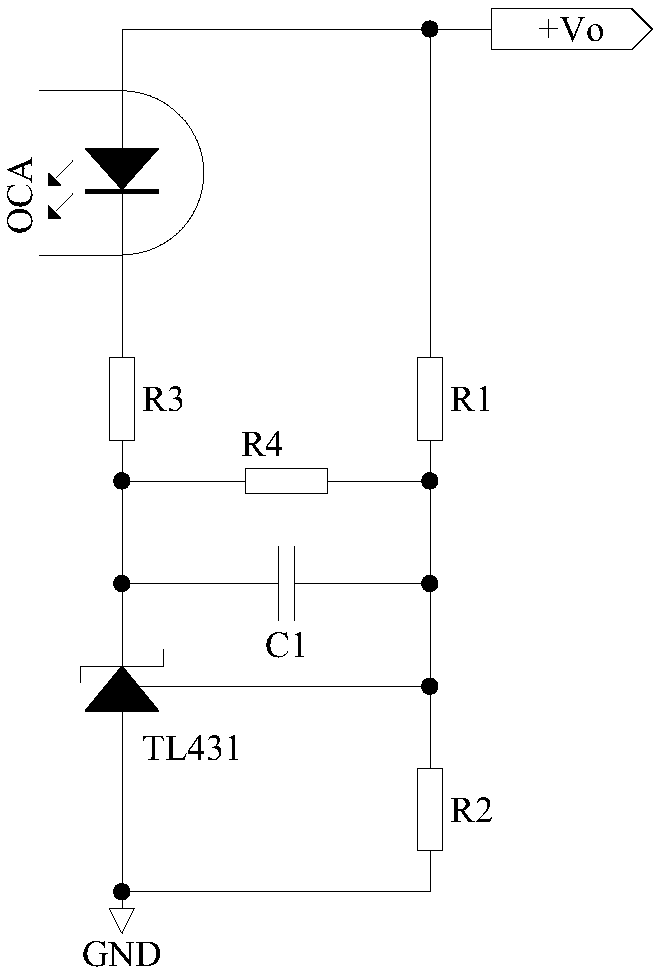

[0027] The converter interconnection system of the present invention realizes automatic input voltage equalization of the converter interconnection system by increasing the voltage adjustment rate of a single converter module. Voltage regulation refers to the change of its output voltage due to the fluctuation of the power supply voltage of the power supply. When designing the circuit, since the voltage adjustment rate reflects the stability of the output voltage of the power supply, the smaller the parameter, the better, and generally it needs to be controlled within 5%. When the voltage adjustment rate is too large, the output voltage accuracy of the power supply cannot meet the requirements of the circuit design.

[0028] However, in the present invention, by sacrificing the precision of the closed-loop control voltage stabilization, the inputs of a single converter module are connected in series and the outputs are connected in parallel to realize the input voltage equaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com