Composite material bending and interlaminar shear sample fast assembly fixture

A technology of interlayer shearing and composite materials, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of inconvenient adjustment and inability to ensure the centering of the position, and achieve the effects of easy operation, accuracy assurance, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

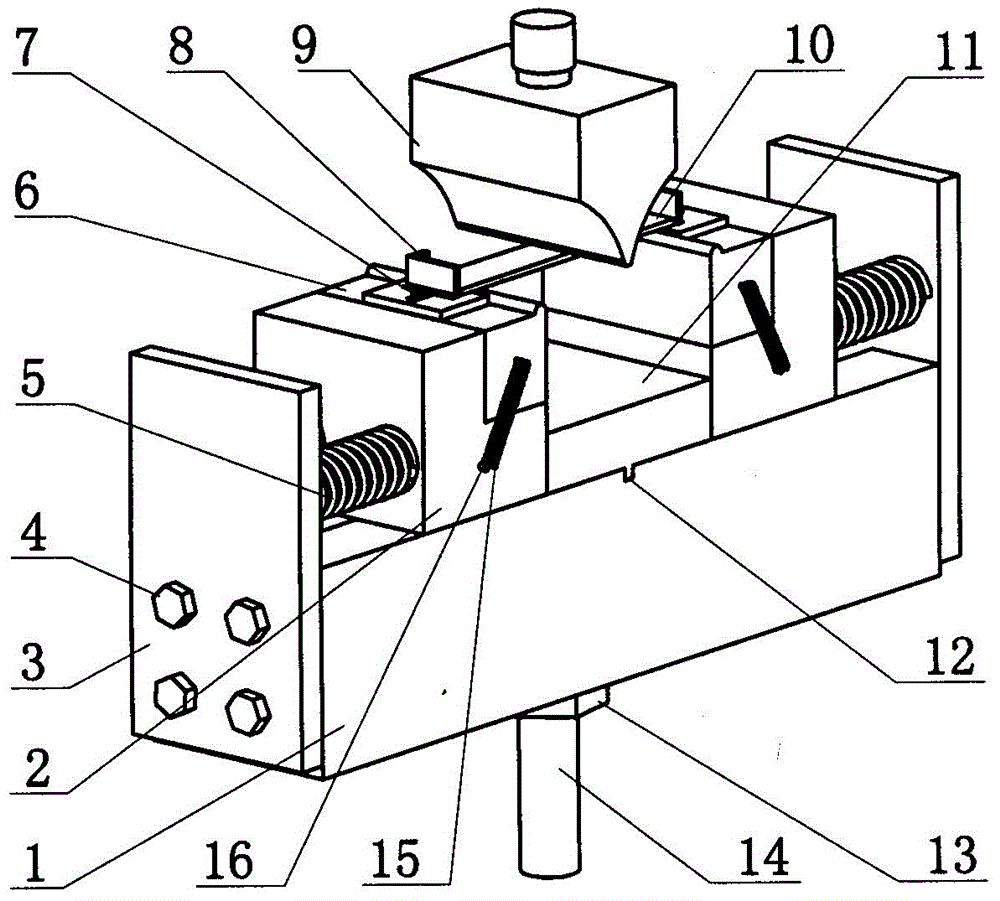

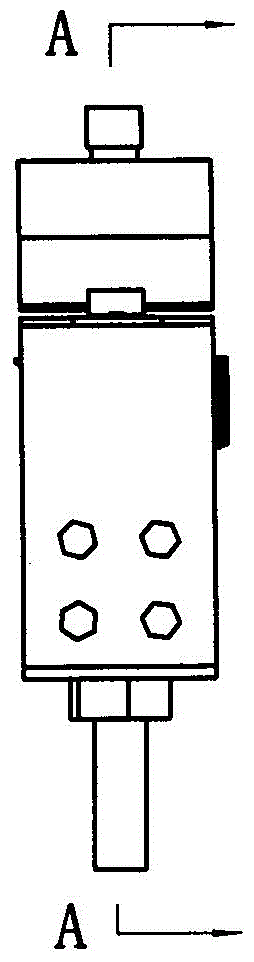

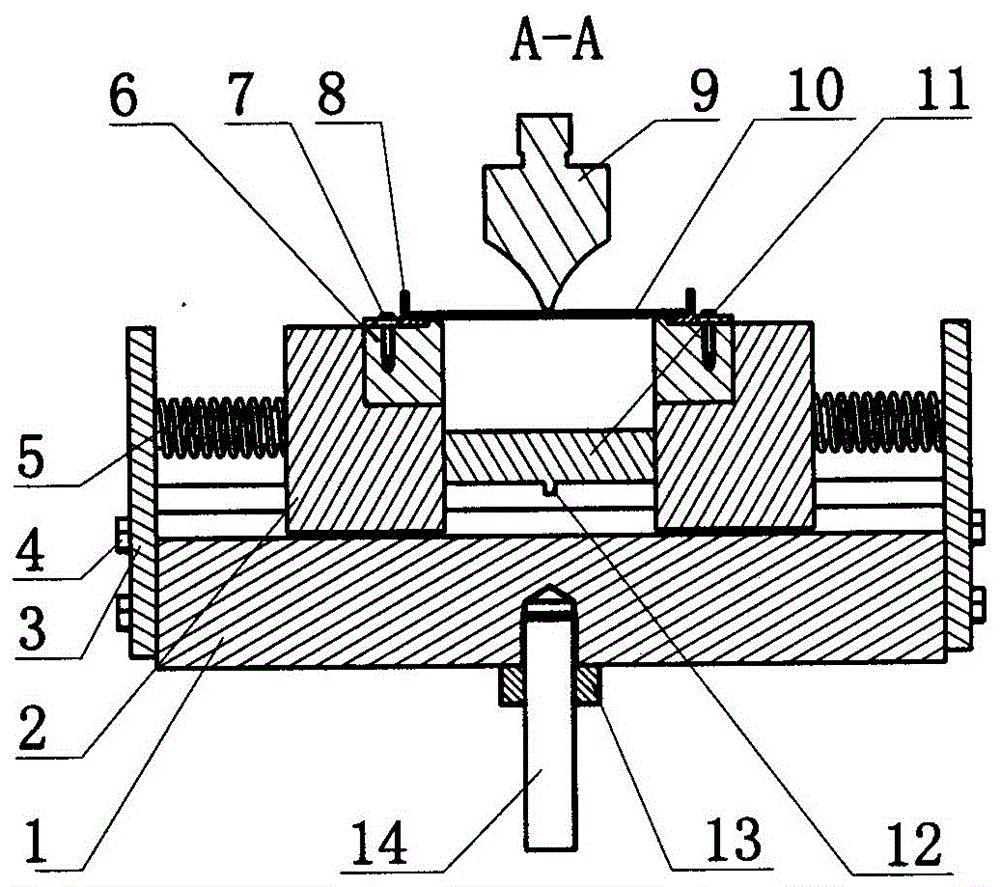

[0020] according to Figure 1-7 The specific structure of the present invention will be described in detail. The composite material bending and interlaminar shear sample quick-loading fixture includes a positioning adjustment assembly and a support seat 1 for assembling the sample 10 between the upper indenter 9 and the lower platform (not shown in the figure) of the mechanical performance testing machine and other parts. Wherein the positioning adjustment assembly is composed of a limit block 8 supporting the sample 10, a support block 6 with a boss, an adjustment pad 11 for adjusting the span, and a slider 2 and the like. The center position of the upper surface of the support base 1 is provided with a positioning centering groove 18, and the bottom of the support base 1 is connected and fixed with the lower platform through a positioning guide rod 14 with a locking nut 13.

[0021] The limit block 8 in the positioning adjustment assembly is provided with a strip-shaped ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com