Preparation method and preparation mold of blind-joint rock mass model sample containing different joint roughness

A technology of sample preparation and hidden joints, which is applied in the field of rock mechanics and rock engineering, can solve the problems of lack of samples of hidden joint rock mass models with different joint roughness and inconvenience, and achieve realistic effects, convenient disassembly and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

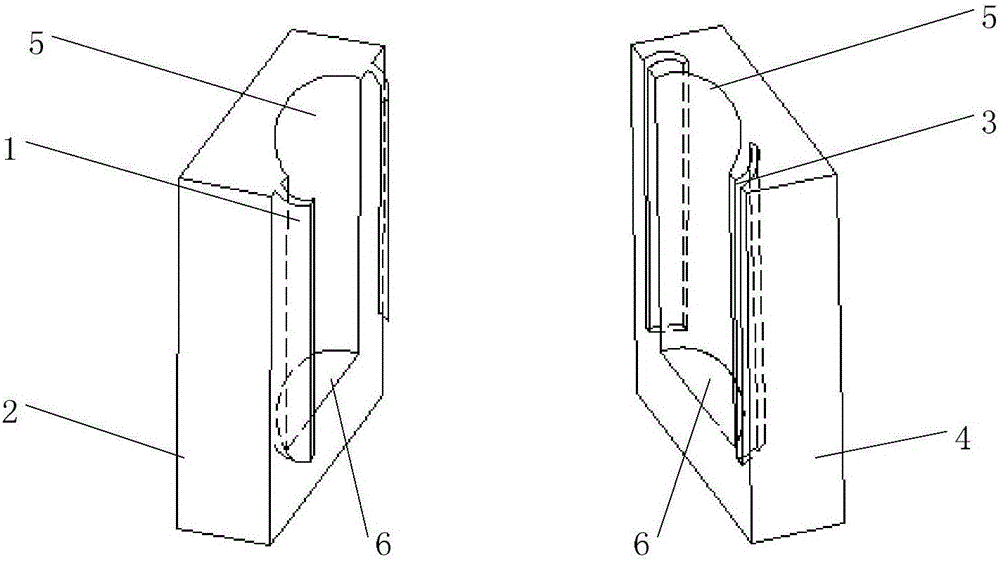

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

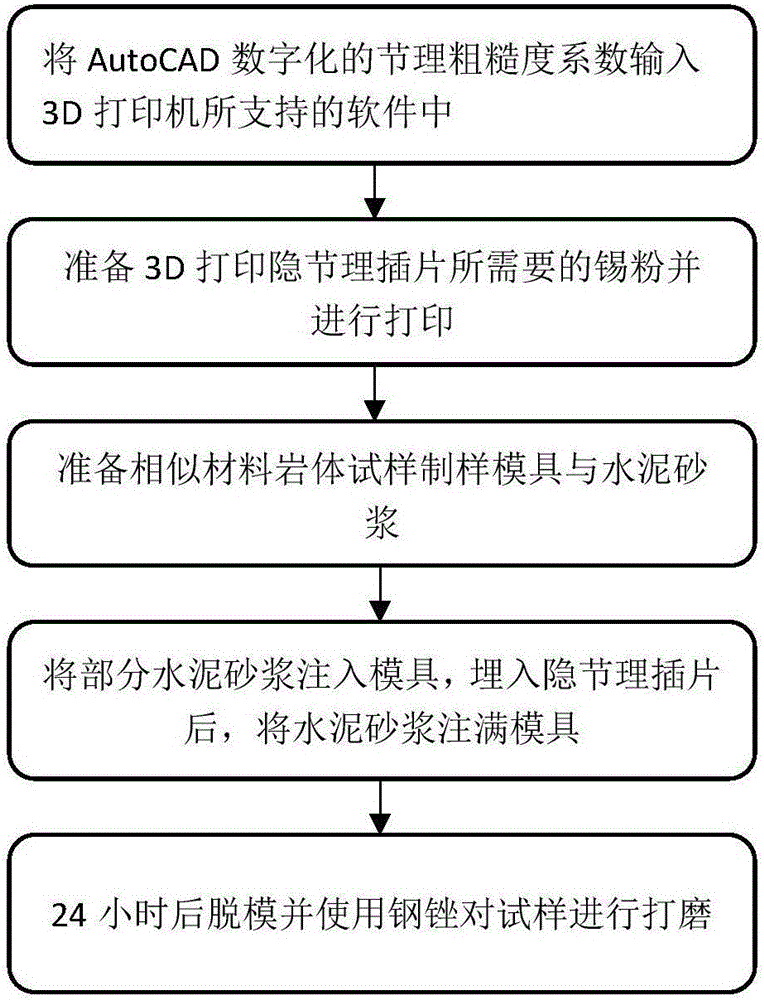

[0029] Taking the preparation of a hidden jointed rock mass model sample with a third-level joint roughness of 4 to 6 as an example, the operation process of this embodiment is as follows figure 1 shown, including the following steps:

[0030] Step 1. Based on 10 standard joint sections, use the computer-aided design software AutoCad to establish hidden joint sample models with different joint roughness, digitize the standard contour curve of the joint roughness coefficient, and input the digitized joint roughness curve into the computer and share it with the 3D printer connected;

[0031] Step 2. Prepare the powdered raw materials and adhesive glue required by the 3D printer and load them into the 3D printer. Print the hidden joint inserts according to the joint roughness curve set in step (1). In this embodiment, low strength is selected. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com