Modular construction method for water distributing system in cold storage tank

A technology of water distribution system and construction method, which can be applied to heat storage equipment, heat exchanger types, lighting and heating equipment, etc. Water cooling system engineering construction period and other issues, to achieve the effect of increasing the Coanda effect, cooling storage efficiency and volume utilization coefficient, and solving low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

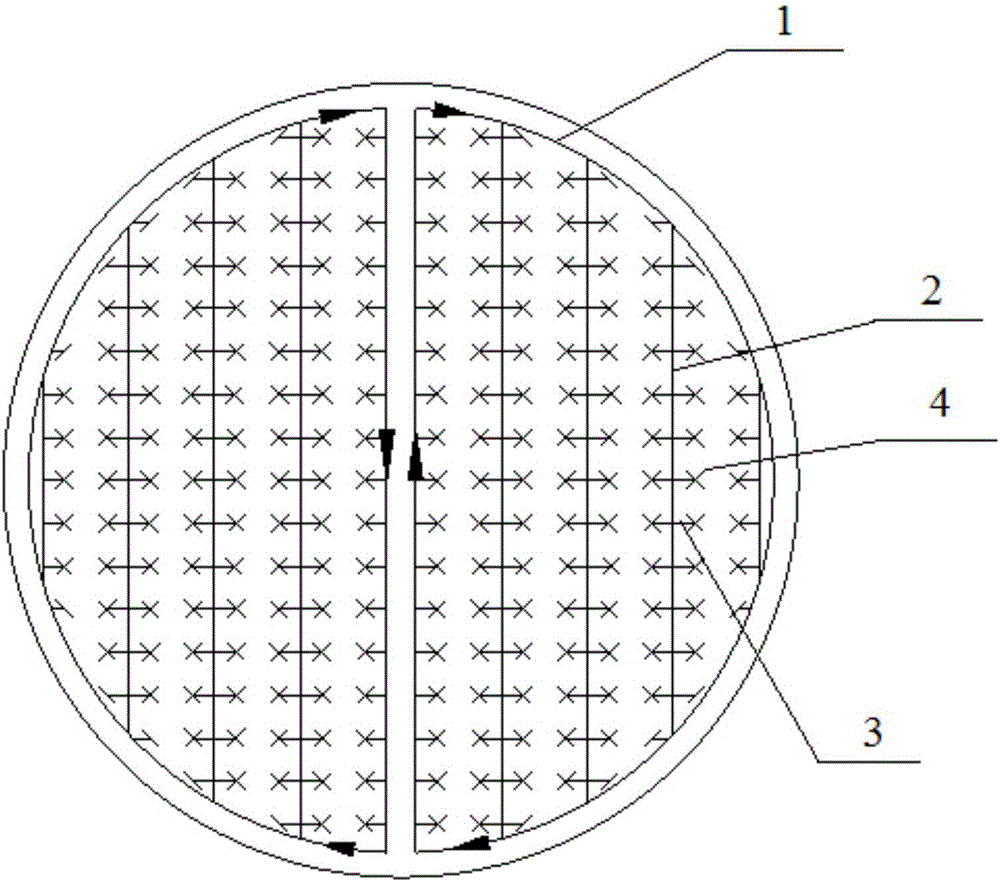

[0038] Embodiment 1: A modular construction method for a water distribution system in a cold storage tank. This method is mainly aimed at large cold storage tanks with a height of 25 to 30 meters and an inner diameter of 25 to 30 meters. The construction includes the following steps:

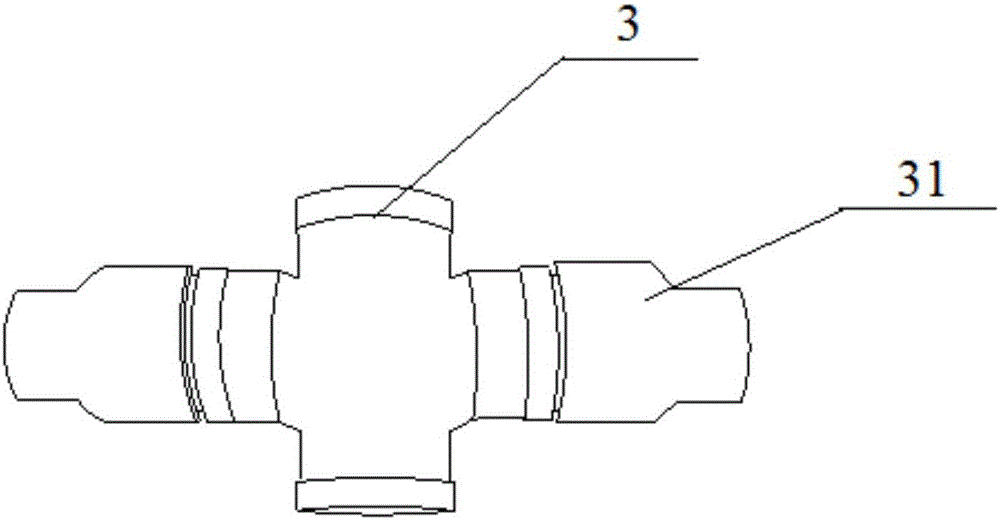

[0039] (1) Collect the structural data of the water distribution components, the water distribution components include water distribution pipes, water distributors and water distribution caps, and use the collected structural data to simulate and arrange the water distribution pipes to obtain the overall model of the water distribution system. The unique RIFD code of the water distribution component in the overall model of the system, according to the code, the corresponding code of the water distribution component;

[0040] (2) Build a water distribution member transmission device at the material delivery port of the cold storage tank;

[0041] (3) Erection of the top irrigation water distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com