Automatic plane bearing assembly machine

A technology for plane bearings and assembly machines, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing production efficiency, troublesome operation, increasing labor costs, etc., and achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

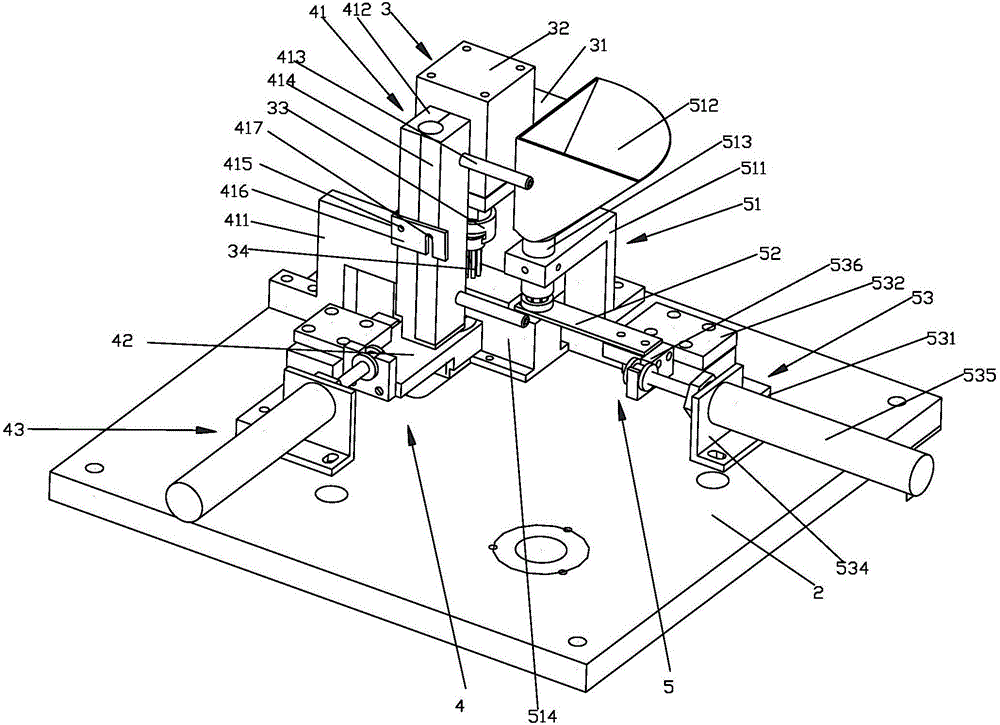

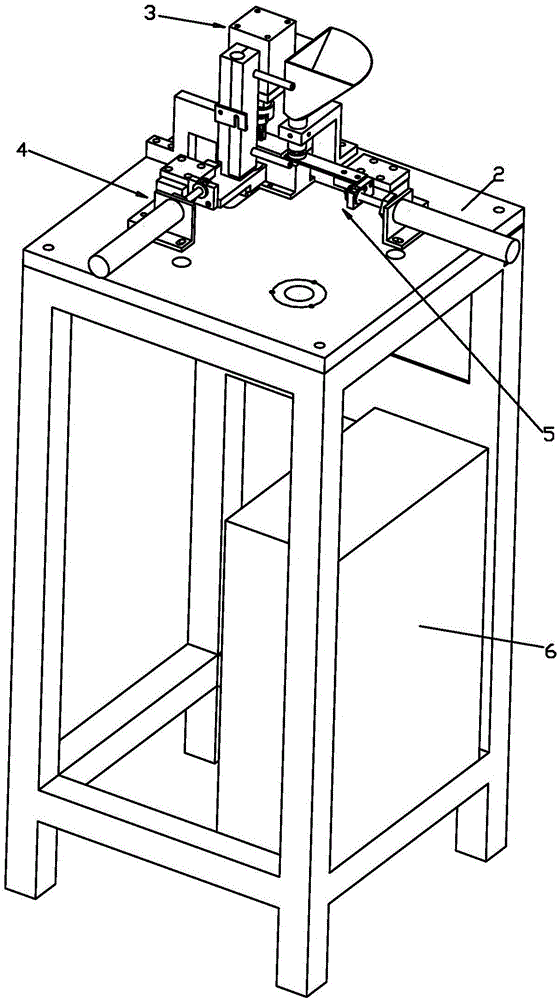

[0050] like figure 2 as well as image 3 As shown, this embodiment proposes an automatic plane bearing assembly machine, including:

[0051] work platform 2;

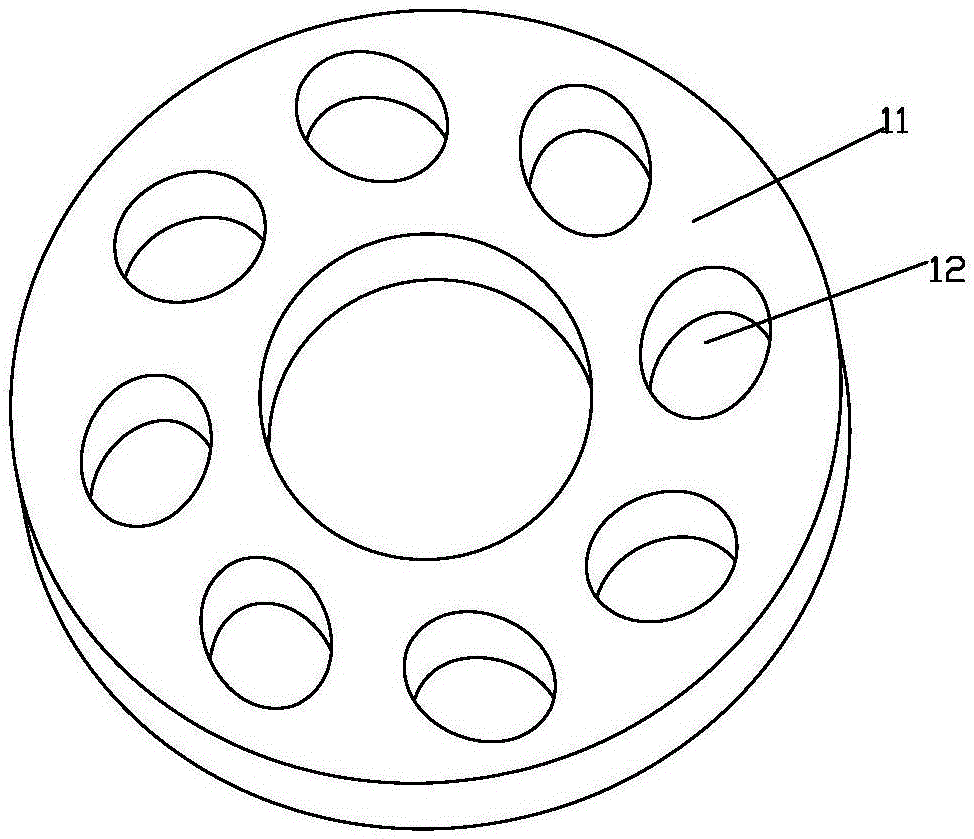

[0052] The ball pressing mechanism 3 includes a ball pressing frame 31, a ball pressing cylinder 32 is arranged on the bead pressing frame 31, the piston rod of the ball pressing cylinder 32 is located in the vertical direction, and the piston rod of the ball pressing cylinder 32 extends downward and is connected with The pressing head 33, the pressing head 33 is provided with a pressing column 34 extending vertically downward, and the number of the pressing column 34 is equal to the number of balls to be pressed into each cage;

[0053] The rack feeding mechanism 4 includes a rack ejection device 41. The rack ejection device 41 can eject the holder from the rack ejection hole on its bottom surface, and a rack cutting piece 42 is provided below the rack ejection hole, and the rack cutting piece 42 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com