Method for judging chemical-viscosity-reduction assisted thickened-oil screw pump lifting technology

An auxiliary screw, chemical viscosity reduction technology, applied in construction and other directions, can solve the problems of lack of judgment means, occupying pump volume, etc., to achieve the effect of reducing trial production losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Take a well in Xinjiang Oilfield as an example to judge the lifting capacity of the screw pump. This oil well only produces oil, no gas or water;

[0060] S100, determine the relevant parameters of the oil reservoir of this well as in Table 2; wherein the wellhead back pressure is 0.5MPA;

[0061] Table 2

[0062]

[0063] S200, daily output 3m 3 / d can determine that the lifting speed is 0.0176m / s, and the reservoir depth can determine that the head of the screw pump is 15.50MPA;

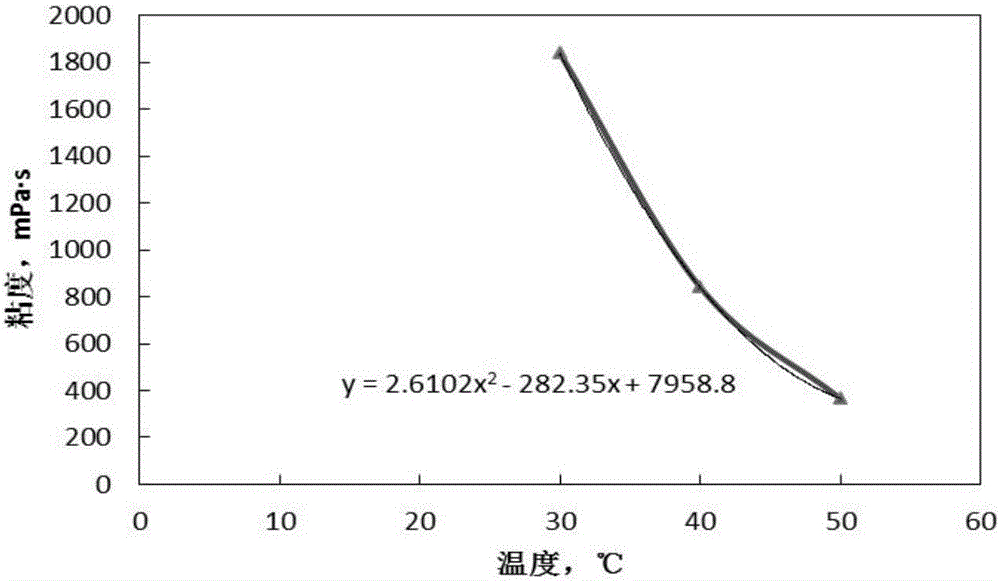

[0064] S300, measure the viscosity-temperature curve of oil reservoir on the spot by the viscosity of crude oil under formation conditions (such as figure 1 );

[0065] S400. Calculate the oil well in sections, and calculate the crude oil viscosity according to the relationship between the reservoir depth and the crude oil viscosity, make a section every 100m, make an average value of the crude oil viscosity every 100m, and calculate the crude oil viscosity at different well depth stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com