Drilling and completion fluid backflow tank with function of automatically crushing internal sedimentary rock debris

A technology for sedimentary rock and drilling and completion, which is applied in the field of drilling and completion fluid recirculation grooves, and can solve the problems of clogging and inconvenient cleaning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

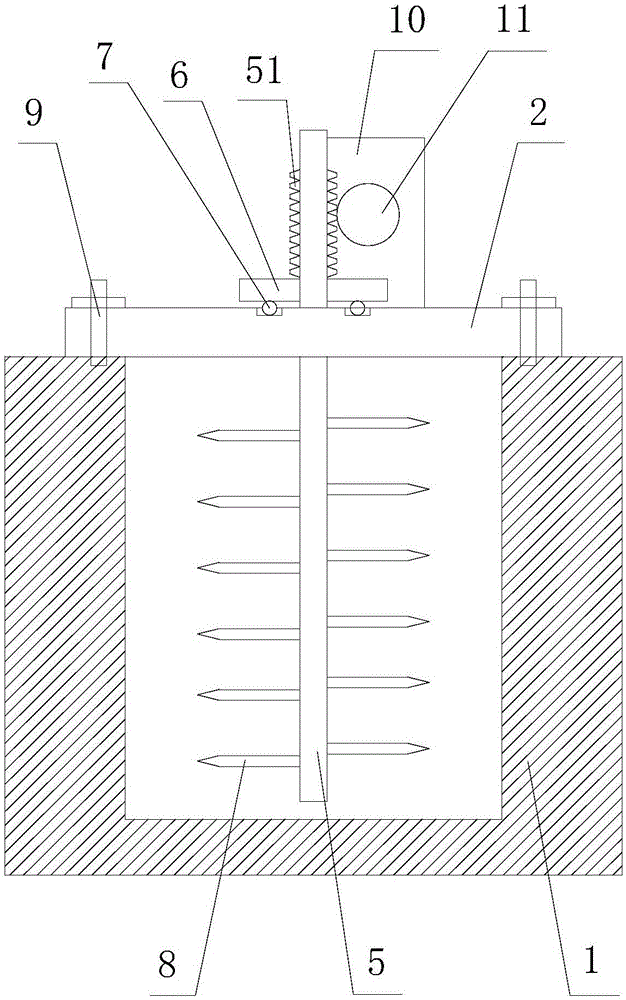

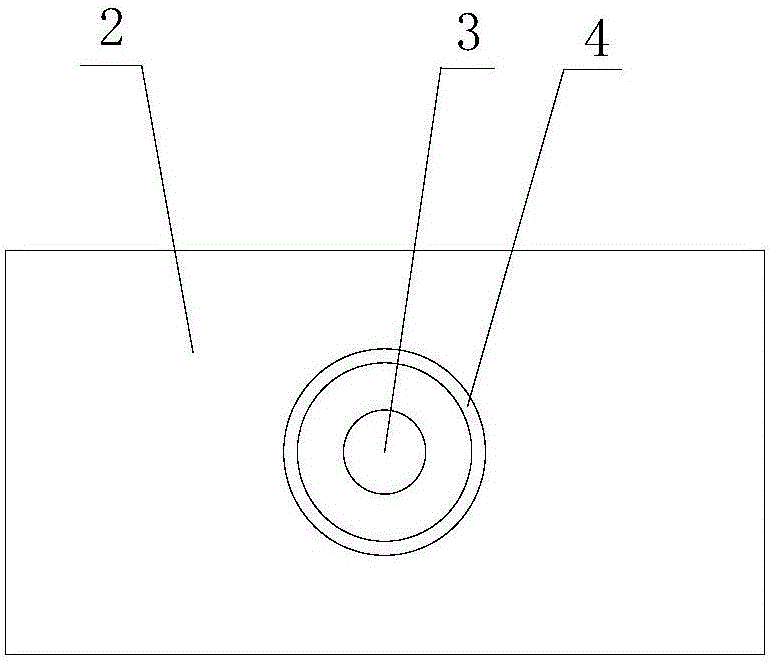

[0024] Such as figure 1 and figure 2The shown drilling and completion fluid backflow tank for automatically crushing internal deposits of debris includes a tank body 1, a plate 2 spanning the tank body 1 is erected at the upper end of the tank body 1, and a circular through hole 3 and a circular through hole 3 are opened in the center of the plate material 2. An annular groove 4, the groove 4 is concentric with the through hole 3, and the through hole 3 is located inside the ring of the groove 4; it also includes a stirring rod 5 passing through the through hole 3, the lower end of the stirring rod 5 The distance between the bottom of the tank body 1 is 5 to 10 cm; the stirring rod 5 is covered with a disc-shaped turntable 6, and the turntable 6 is fixedly connected to the stirring rod 5; the upper and lower surfaces of the turntable 6 are perpendicular to the stirring The axis of the stick 5, and the lower surface of the turntable 6 is provided with N rollers 7, and the N r...

Embodiment 2

[0026] Such as figure 1 and figure 2 The shown drilling and completion fluid return tank for automatically breaking the internal sedimentary debris, on the basis of Example 1, is aimed at the well wall with a diameter of 5 to 8 cm in the returned drilling fluid. Therefore, the lower end of the stirring rod 5 is set The distance from the bottom of the tank body 1 is 10 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com