Maintenance platform monolithic movement construction method

A technology for repairing platforms and construction methods, which is applied in building maintenance, industrial construction, construction, etc., can solve the problems of large labor and machinery costs, increased construction costs, and long construction periods, achieving low labor and machinery costs, Short construction period and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

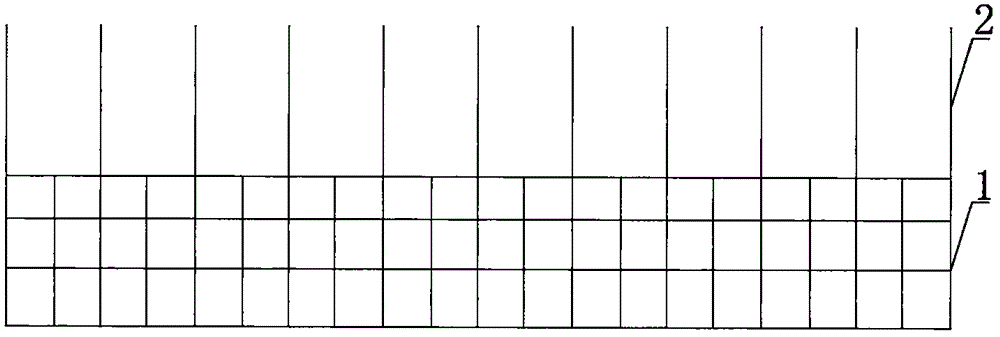

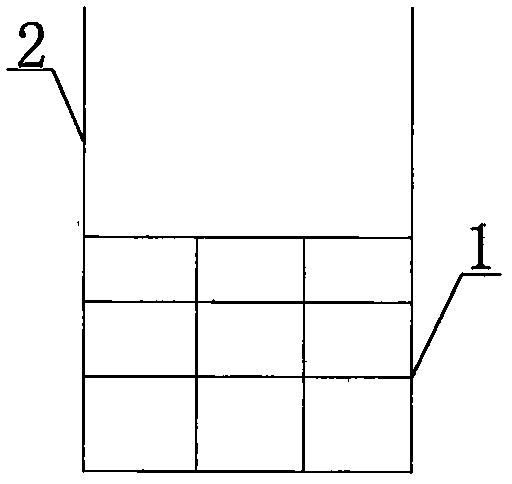

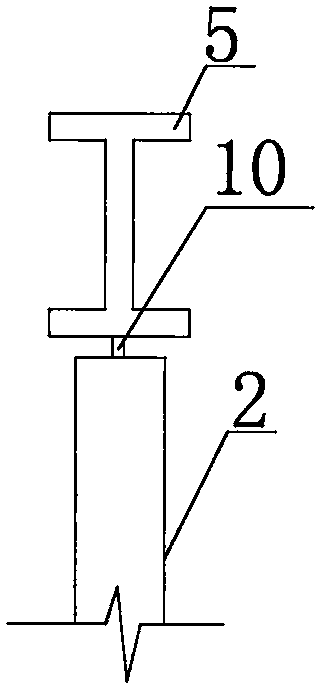

[0017] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , the present invention relates to an overall translational construction method of the maintenance platform. Firstly, a C-shaped load-bearing lifting lug 3 is connected to both sides of each suspender 2 connected to the maintenance platform 1, and the C-shaped load-bearing lifting lug 3 is processed by a steel plate. The middle part of its upper end is connected with a bearing 4 and installed on the lower flange of the roof beam 5, and its lower end is connected with the boom 2 connected to the maintenance platform 1; The middle part of the upper end of the rod 2 is connected with a traction lug 6, the traction lug 6 is processed by steel plate, a round hole is opened in the middle and an electric reverse chain 7 is connected to it; The two suspenders 2 corresponding to both sides are connected into one body, and all the struts 8 are connected into one body with the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com